Transverse-butt-joint welding method for hull structural steel and forged steel

A technology of structural steel and welding methods, applied in welding equipment, welding/welding/cutting items, arc welding equipment, etc., can solve problems such as low weld strength and heavy welding workload, so as to ensure welding quality and eliminate welding Effects of reducing stress and reducing welding workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Embodiment 1, comprises the following steps:

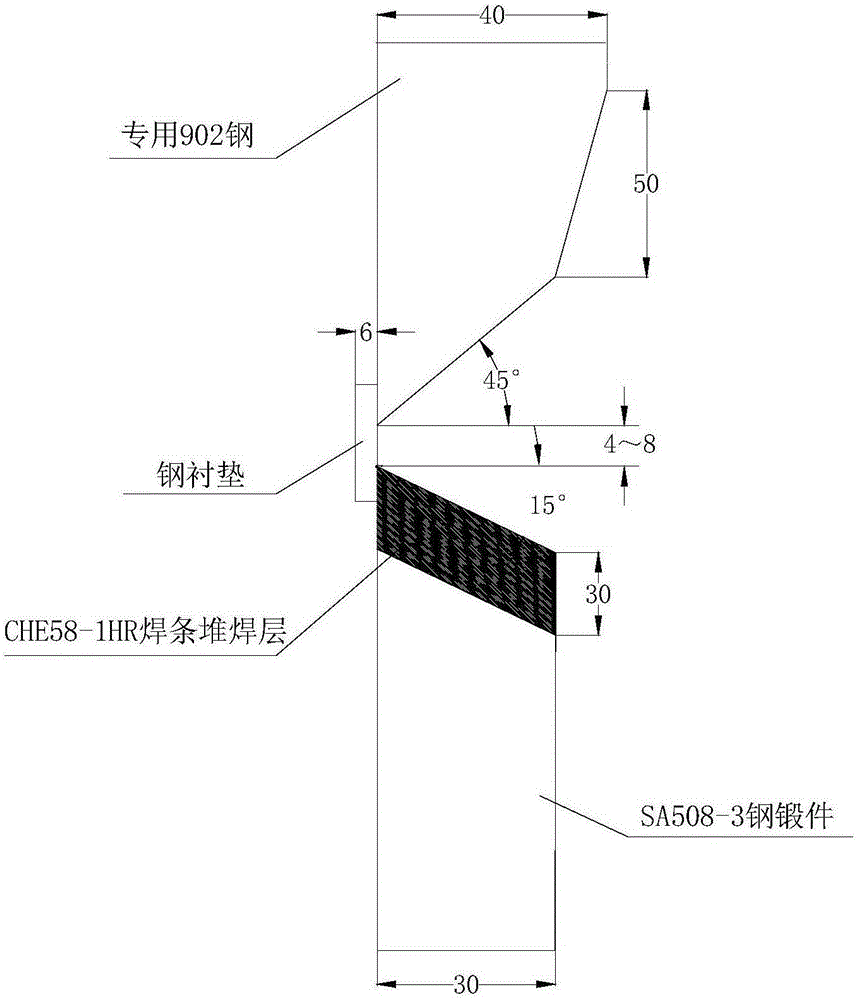

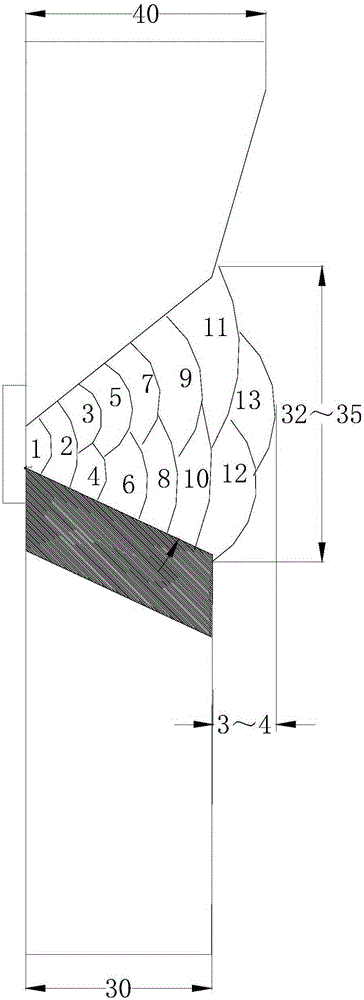

[0022] (1) Groove forming steps: such as figure 1 As shown, grooves are formed on the butt joints of special 902 steel with a thickness of 40mm and SA508-3 forged steel with a thickness of 30mm without leaving roots. 30°, forming a single V-shaped butt joint groove when butt joint, the butt joint groove angle is 60 °, the part of the special 902 steel side thicker than the SA508-3 forged steel is beveled, and the bevel length is 50mm, so that the two sides of the butt joint bevel Contour height; water stains, oil stains, rust, hanging slag and other sundries that affect the welding quality should be removed from the end faces within 50mm of the groove and both sides of the groove;

[0023] (2) One-side surfacing welding step: Preheat the SA508-3 forged steel groove area to 120°C, and then use manual arc welding and φ4mm CHE58-1HR electrode to perform surfacing welding on the SA508-3 forged steel groove. The shape of the l...

Embodiment 2

[0029] Embodiment 2, is exactly the same as the step of embodiment 1, and difference is only in the process parameter in each step:

[0030] In the groove forming step, the inclination angle of the special 902 steel side bevel is 20° larger than that of the SA508-3 forged steel side bevel, the angle of the butt joint groove is 55°, and the beveling length is 45mm;

[0031] In the surfacing step on one side, preheat to 80°C;

[0032] Preheating step The gap between the butt groove and the groove is 4mm, the angle of the butt groove is 55°, and a Q345R steel liner with a thickness of 4mm is installed; the preheating temperature reaches 80°C and starts welding;

[0033] In the welding step, the temperature between passes during welding is controlled at 80°C.

[0034] In the single-side surfacing welding step and welding step of each of the above-mentioned embodiments, the electrodes involved need to be baked at 380-400°C for 1-2 hours before welding, and put them into the heat p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com