Pure inorganic microporous desiccant and synthetic method thereof

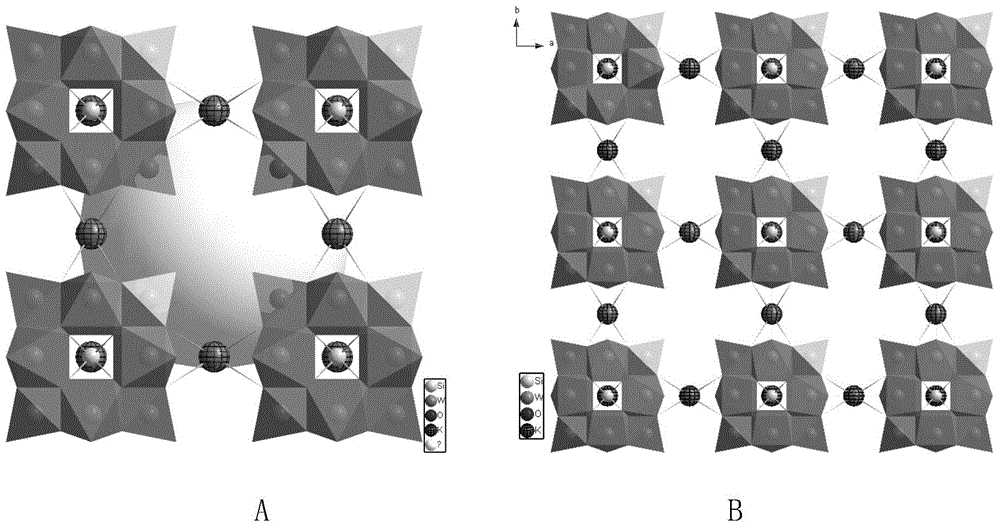

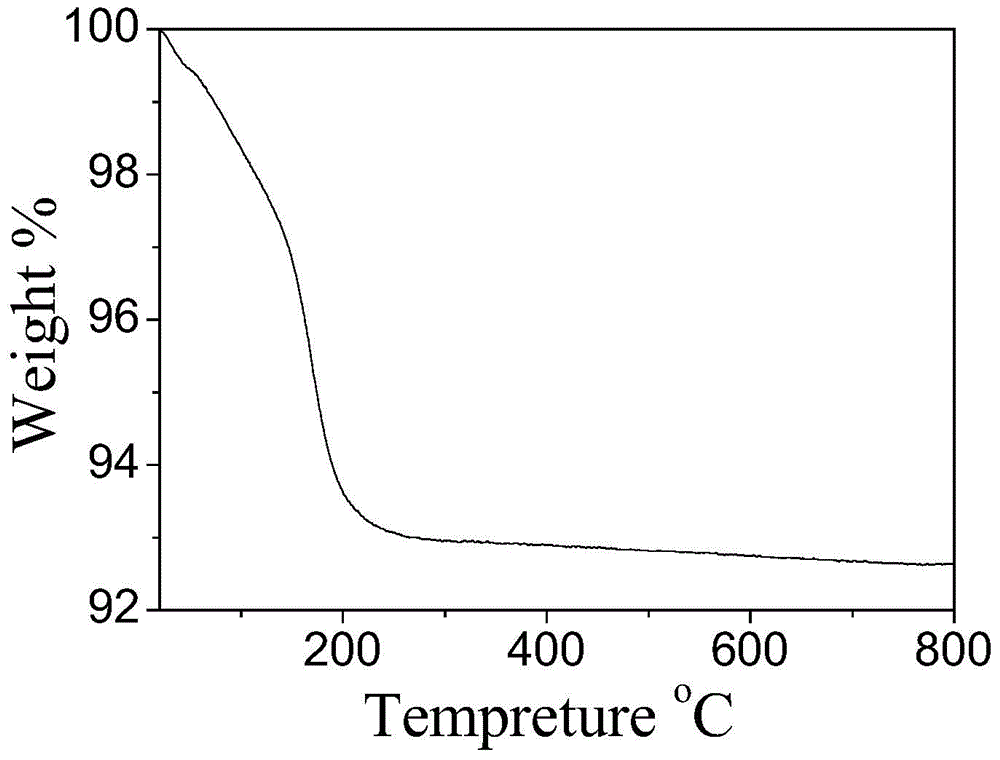

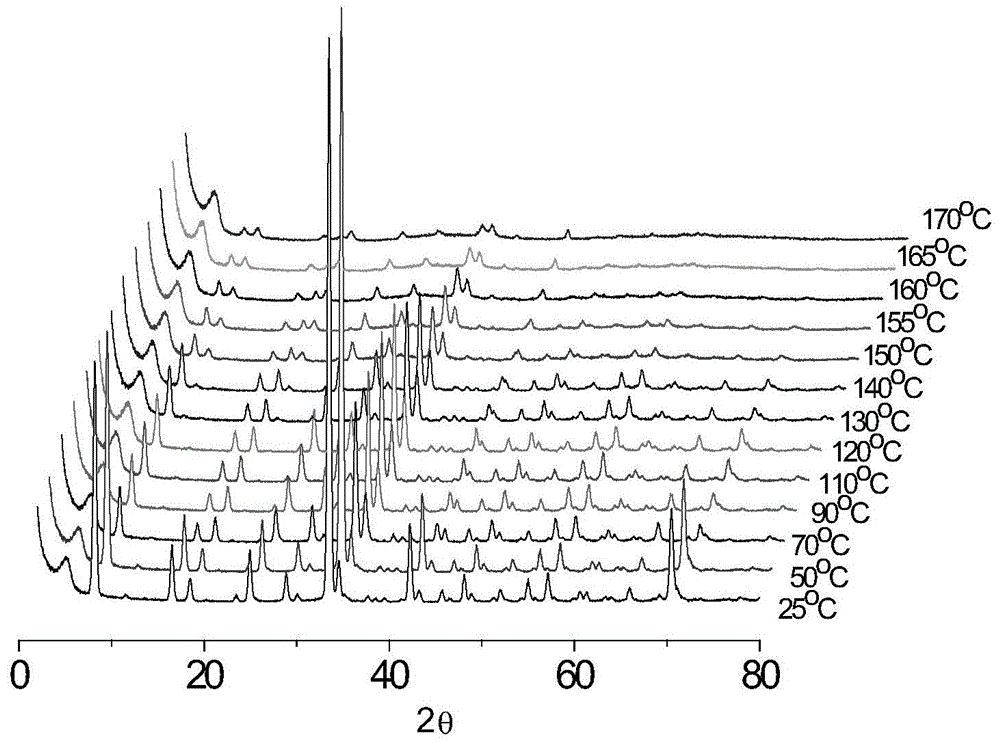

A synthesis method and desiccant technology, applied in the field of inorganic microporous new material desiccant, can solve the problems of rare reports of heteropolyacid microporous materials, and achieve the effects of high molecular weight, large molecular volume and enhanced adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] A synthetic method of pure inorganic microporous desiccant, comprising the following steps:

[0025] (1) Weigh 55mmol of Na 2 WO 4 ·2H 2 O18.2g was placed in a 100mL beaker, dissolved in 30mL distilled water, and under stirring at room temperature, 16.5mL of 4.0M hydrochloric acid was added dropwise to obtain solution A;

[0026] (2) Weigh 5mmolNa 2 SiO 3 1.1 g was dissolved in 10 mL of distilled water to obtain solution B;

[0027] (3) solution B is poured into solution A to obtain solution C;

[0028] (4) Under vigorous stirring, adjust the pH of solution C to 5.0-6.0 with 4.0M HCl, and then stir at room temperature for 100 min;

[0029] (5) under electromagnetic stirring then, add 9.0g solid KCl to the solution of step (4), separate out a large amount of white solid after 15min, vacuum pump suction filtration, place drying at room temperature to obtain white solid K 8 SiW 11 O 39 ;

[0030] (6) Weigh K with a weight of 1.0g 8 SiW 11 O 39 ·14H 2 O was di...

Embodiment 2

[0040] The remaining conditions are the same as in Example 1, the difference is that in step (8), the aqueous solution of 4mL2.0MKCl was added dropwise at a rate of 50 drops per minute, stirred at room temperature for 30min, filtered, and the filtrate was allowed to stand at room temperature for two days to separate out colorless tetragonal crystals , the yield was 84.2%.

Embodiment 3

[0042] The remaining conditions are the same as in Example 1, the difference is that in step (8), the aqueous solution of 6mL of 2.0MKCl was added dropwise at a rate of 50 drops per minute, stirred at room temperature for 30min, filtered, and the filtrate was allowed to stand at room temperature for two days to separate out colorless tetragonal crystals , the yield was 84.5%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com