Treatment method for oil field acidic sewage

A technology of acid sewage and treatment method, applied in the field of oilfield sewage treatment, can solve the problems of slow speed, use of chemical agents, and high cost, and achieve the effects of reducing the tendency of sewage to scale, inhibiting the growth of anaerobic bacteria, and controlling the content of active oxygen.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

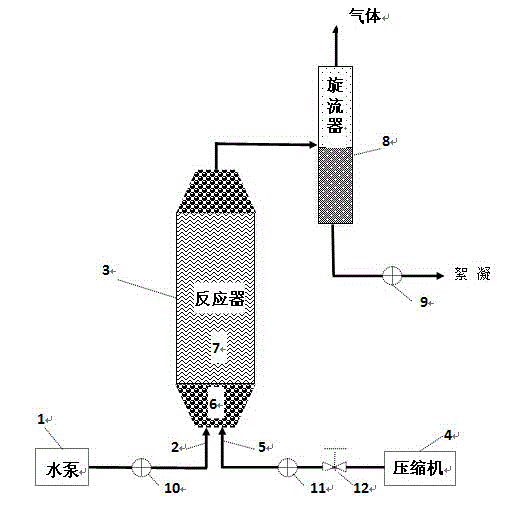

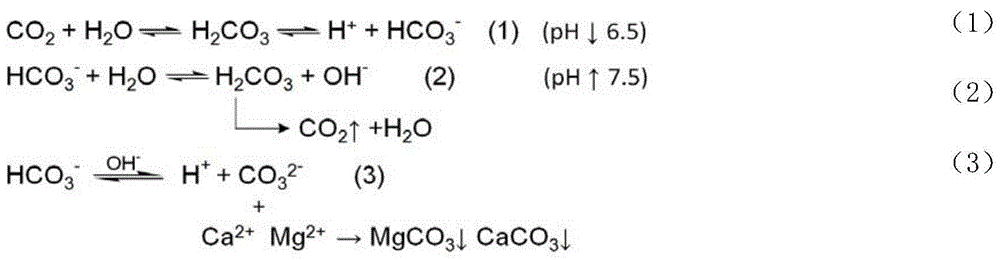

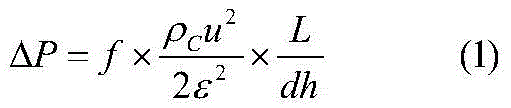

[0042] First, the air or nitrogen and the acidic sewage from the oilfield flow together through the tubular static mixer for gas-liquid mixing, and the gas-liquid volume ratio is controlled to be 3.0 at 55°C. The time for passing through the tubular static mixer is 2 seconds, and the pH value is increased to 7.0, and then through the gas-liquid cyclone separation, the sewage desorbed from the acid gas is sent to the flocculation and sedimentation process, and finally the water from the flocculation and sedimentation to separate the sediment is discharged. The gas-liquid dispersion is less than 0.5 mm; the Reynolds number of the gas-liquid mixed flow state is greater than 3000.

[0043] In this embodiment, the method of the present invention is used to carry out rapid and efficient gas-liquid mixing for the oilfield acid sewage obtained through the three-phase separator, after the first oil removal tank, the sewage oil content is low. Use a compressor to press the air into the ...

Embodiment 2

[0050]First, the air or nitrogen and the acidic sewage from the oilfield flow together through the tubular static mixer for gas-liquid mixing, and the gas-liquid volume ratio is controlled at 65°C to be 2.5. The time for passing through the tubular static mixer is 5 seconds, and the pH value is increased to 7.5, then through the gas-liquid cyclone separation, the sewage desorbed from the acid gas is sent to the flocculation and sedimentation process, and finally the water from the flocculation and sedimentation to separate the sediment is discharged. The gas-liquid dispersion is less than 0.5 mm; the Reynolds number of the gas-liquid mixed flow state is greater than 3000.

[0051] In this embodiment, the method of the present invention is used for rapid and efficient gas-liquid mixing in the case where the oilfield acid sewage obtained through the three-phase separator has a high oil content before the primary oil removal tank. At this time, the sewage has a higher oil content...

Embodiment 3

[0057] First, the air or nitrogen and the acidic sewage from the oilfield flow together through the tubular static mixer for gas-liquid mixing, and the gas-liquid volume ratio is controlled at 58°C to be 2.8. The time for passing through the tubular static mixer is 4 seconds, and the pH value is increased to 7.1, then through the gas-liquid cyclone separation, the sewage that desorbs the acid gas is sent to the flocculation and sedimentation process, and finally the water from the flocculation and sedimentation to separate the sediment is discharged. The gas-liquid dispersion is less than 0.5 mm; the Reynolds number of the gas-liquid mixed flow state is greater than 3000.

[0058] In this example, the oil field acid sewage contains CO 2 and H 2 S, and in the case of a lower pH value, the method of the present invention is used to carry out rapid and efficient gas-liquid mixing before the primary oil removal tank. Use a compressor to press the air into the SV-type static mixe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Reynolds number | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com