Fertilizer for conditioning soil quality and preparation method thereof

A technology for conditioning soil fertilizers and main materials, applied in fertilizer mixtures, fertilization devices, applications, etc., can solve problems such as straw burning, and achieve the effect of prolonging fertilizer efficiency, reducing fertilizer loss and weeding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

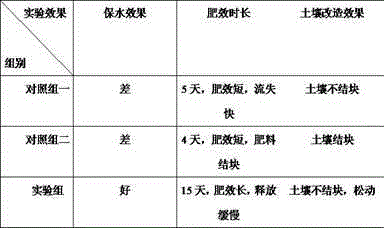

Image

Examples

Embodiment 1

[0025] A fertilizer for conditioning soil, including the following main materials in parts by weight: 40 parts of pond mud, 15 parts of deer vine, 17 parts of attapulgite, 12 parts of blast furnace slag, 14 parts of bone meal and 30 parts of corn stalks, including the following parts by weight Additives: 10 parts of acrylate, 6 parts of sodium humate, 2 parts of hydrogen sulfide, 1 part of Bacillus subtilis, 4 parts of urease inhibitor, 5 parts of diazepam, 7 parts of potassium dihydrogen phosphate and brassin 12 parts of lactone.

[0026] A preparation method for conditioning soil fertilizer, comprising the following steps:

[0027] 1) Take 30 parts of deervine and 30 parts of corn stalks and grind them through a grinder to completely destroy the fibers of the roots, branches and leaves, and then cut the fibers into pieces with a rotary cutter for later use;

[0028] 2) Take 17 parts of attapulgite, first grind and pulverize attapulgite, filter and dry to obtain purified att...

Embodiment 2

[0037] A fertilizer for conditioning soil, including the following main materials in parts by weight: 35 parts of pond mud, 22 parts of deer vine, 22 parts of attapulgite, 15 parts of blast furnace slag, 17 parts of bone meal and 33 parts of corn stalks, including the following parts by weight Additives: 12 parts of acrylate, 8 parts of sodium humate, 4 parts of hydrogen sulfide, 2 parts of Bacillus subtilis, 5 parts of urease inhibitor, 6 parts of diazepam, 9 parts of potassium dihydrogen phosphate and brassin 14 parts of lactones.

[0038] A preparation method for conditioning soil fertilizer, comprising the following steps:

[0039] 1) Take 20 parts of deervine and 33 parts of corn stalks and grind them through a grinder to completely destroy the fibers of the roots, branches and leaves, and then cut the fibers into pieces with a rotary cutter for later use;

[0040] 2) Take 22 parts of attapulgite, first grind and pulverize attapulgite, filter and dry to obtain purified a...

Embodiment 3

[0050] A fertilizer for conditioning soil, including the following main materials in parts by weight: 30 parts of pond mud, 30 parts of deer vine, 29 parts of attapulgite, 18 parts of blast furnace slag, 20 parts of bone meal and 36 parts of corn stalks, including the following parts by weight Additives: 14 parts of acrylate, 9 parts of sodium humate, 5 parts of hydrogen sulfide, 3 parts of Bacillus subtilis, 6 parts of urease inhibitor, 7 parts of diazepam, 11 parts of potassium dihydrogen phosphate and brassin 16 parts of lactones A kind of preparation method of conditioner soil quality fertilizer, comprises the following steps:

[0051] 1) Take 30 parts of deervine and 36 parts of corn stalks and grind them through a grinder to completely destroy the fibers of the roots, branches and leaves, and then cut the fibers into pieces with a rotary cutter for later use;

[0052] 2) Take 29 parts of attapulgite, first grind and pulverize attapulgite, filter and dry to obtain purifie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com