Anti-high temperature, anti-high salinity and anti-condensate foaming agent and preparation method thereof

A high-salinity, anti-condensate oil technology, applied in chemical instruments and methods, drilling compositions, etc., can solve the problem of not being able to meet high temperature resistance, high-salinity anti-condensate oil, and foaming capabilities at the same time And stability reduction, poor foam stability and other problems, to achieve the effect of improving water carrying capacity, good foam stability, and strong foaming ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A foaming agent resistant to high temperature, high salinity and condensate oil. The foaming agent is composed of the following components by weight:

[0034] Anionic surfactant 30-50%;

[0035] Amphoteric surfactant 10-20%;

[0036] Fluorocarbon surfactant 1~2%;

[0037] Foam stabilizer 0.5~1.5%;

[0038] Triethanolamine 0.2~0.5%;

[0039] Ethylene glycol 0.2~0.5%;

[0040] Sodium salt 3~5%;

[0041] The rest is water.

[0042] A preparation method of a high-temperature-resistant, high-salinity-resistant and condensate-resistant foaming agent:

[0043] (1) Measure 30-50% of anionic surfactant, 10-20% of amphoteric surfactant, 1-2% of fluorocarbon surfactant, 0.5-1.5% of foam stabilizer, 0.2-0.5% triethanolamine, 0.2-0.5% ethylene glycol, and 3-5% sodium salt are used as raw materials for standby;

[0044] (2) Take the amount measured in step (1), add the anionic surfactant, amphoteric surfactant, fluorocarbon surfactant and sodium salt weighed in step (1) into ...

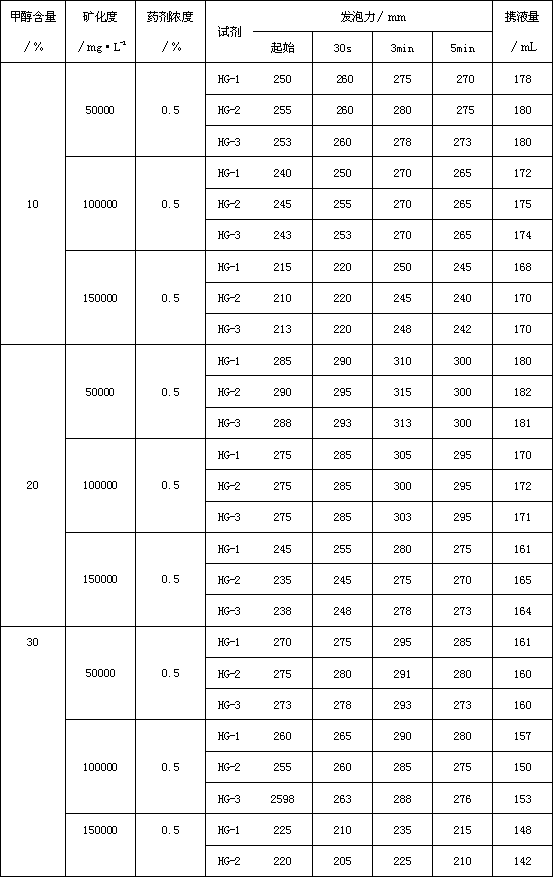

Embodiment 2

[0052] The foaming agent (code name HG-1) provided in this example is prepared according to the following raw material components:

[0053] (1) Take sodium alkylbenzene sulfonate with a weight ratio of 30, 20% cocophthaloaminopropyl betaine, 1% potassium perfluorohexyl sulfonate, 1.5% polyvinyl alcohol, and 0.3% Triethanolamine, the ethylene glycol of 0.3%, the sodium chloride of 3% is standby as raw material;

[0054] (2) Take the amount measured in step (1), add the sodium alkylbenzene sulfonate, cocophthalamidopropyl betaine, potassium perfluorohexyl sulfonate and sodium chloride weighed in step (1) respectively and stir Stir in the cylinder and heat to 30-50°C;

[0055] (3) Add the polyvinyl alcohol measured in step (1) into the mixing tank in step (2), and stir at a constant temperature until all the materials added to the mixing tank are dissolved;

[0056] (4) Take the triethanolamine, ethylene glycol and water measured in step (1) and add them to the mixing tank in s...

Embodiment 3

[0059] The foaming agent (code name HG-2) provided in this example is prepared according to the following raw material components:

[0060] 1) Take 40% sodium alkyl sulfonate, 15% dilauryl amidopropyl amine oxide, 2% ethyl perfluoroalkylamide, 1% sodium lauryl sulfate, 0.5 % triethanolamine, 0.2 ethylene glycol, and 5% sodium sulfate are standby as raw materials;

[0061] (2) Take the amount measured in step (1) and add the sodium alkylsulfonate, dilauryl amidopropyl amine oxide, ethyl perfluoroalkylamide and sodium sulfate weighed in step (1) into the mixing tank respectively Stir and heat to 30-50°C;

[0062] (3) Take the sodium lauryl sulfate measured in step (1) and add it to the mixing tank in step (2), and stir at a constant temperature until all the materials added to the mixing tank are dissolved;

[0063] (4) Take the triethanolamine, ethylene glycol and water measured in step (1) and add them to the mixing tank in step (3) in sequence, and stir at a constant temperat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com