Wine deacidification method

A wine and acid-reducing technology, which is applied in the field of wine acid-reducing treatment, can solve the problems of acid taste of the original wine, low acid-reducing utilization rate and long duration, and achieves novel method, good acid-reducing effect and little impact on sensory quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Acid-reducing treatment of longan dry white wine:

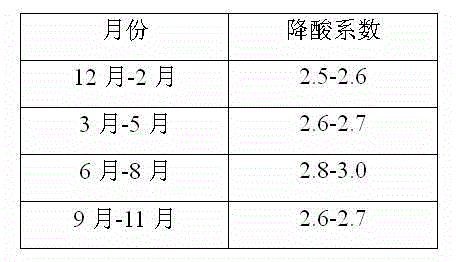

[0024] The quantity of original wine is 30 tons, the initial titration acid value of original wine is 7.9g / l, the target value is 6.2±0.2g / l, and the time is April. The calculation formula is as follows (assuming that the acid reduction coefficient is 2.7, refer to Table 1 for the selection method of the acid reduction coefficient):

[0025] Potassium hydrogen tartrate dosage = (original titration acid value 7.9g / l-target titration acid value 6.2g / l) × 2.7 × Original wine volume 30000 (L) ÷ 1000 = 137.7kg

[0026] The amount of potassium carbonate = the amount of potassium hydrogen tartrate / 2.7=137.7kg / 2.7=51kg

[0027] The acid reduction coefficient is selected between 2.5-3.0 due to the difference in ambient temperature. When the temperature is high in summer, the solubility of hydrogen tartrate is high, which is not conducive to sedimentation, so the acid reduction coefficient is taken at a higher value; when the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com