High-strength aluminum alloy fin material as well as preparation method and application thereof

An aluminum alloy, high-strength technology, which is applied in the field of ultra-thin, high-temperature-resistant and high-strength aluminum alloy fin materials containing light and heavy rare earths and its preparation, can solve the problem of not describing the disadvantages of magnesium and copper, disadvantageous brazing performance, and reduced corrosion resistance, etc. problem, to achieve the effect of improving corrosion resistance, heat resistance, good corrosion resistance and good electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

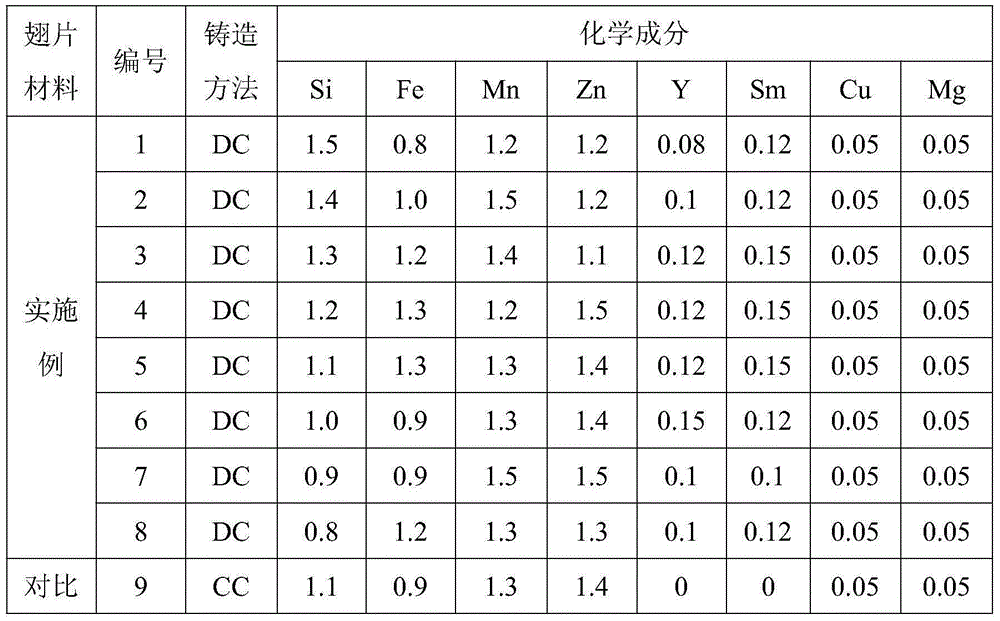

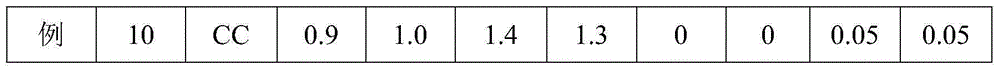

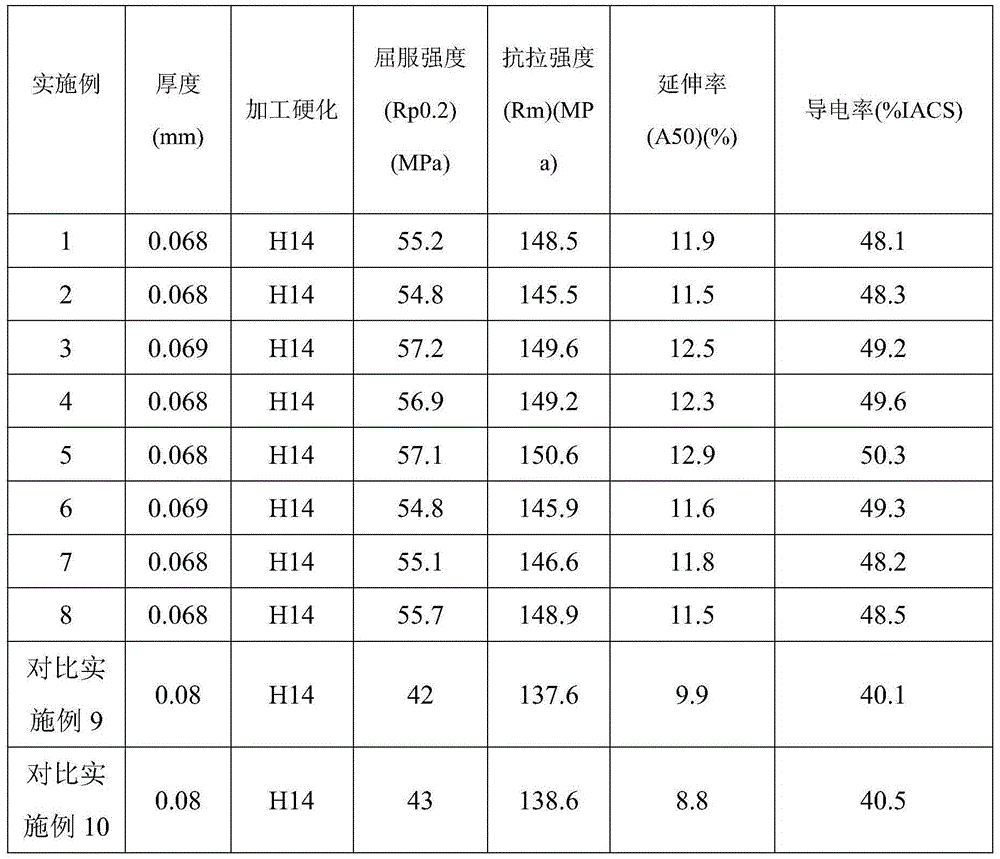

Embodiment 1-8 and comparative example 9-10

[0032] According to the alloy composition of Examples 1-8 shown in Table 1, the specific steps for smelting using a common aluminum alloy smelting process are as follows:

[0033] (1) The alloy is smelted according to the proportioning ratio, and cast into an ingot by a direct quenching casting method;

[0034] (2) hot rolling the product of step (1) after heat treatment annealing, annealing, and then cold rolling;

[0035] (3) Annealing to obtain the used state of the fin material.

[0036] in:

[0037] In step (1), in Examples 1 to 4, the casting speed of the ingot is 55mm / min, and the water velocity at the head of the ingot is 800m 3 / h, the water velocity at the tail of the ingot is 2500m 3 / h, the water velocity at the tail of the ingot is 2000m 3 / h;

Embodiment 5~8

[0038] In Examples 5-8, the casting speed of the ingot is 40mm / min, and the water velocity at the head of the ingot is 800m 3 / h, the water velocity at the tail of the ingot is 3000m 3 / h;

[0039] In step (2), in Examples 1-4, heat treatment and annealing at 480°C for 2 hours, after annealing, enter the rolling mill for hot rolling at 480°C, the final rolling temperature is 310°C, and the final thickness of hot rolling is 3mm; annealing before cold rolling, annealing The temperature is 360°C, and the time is 1h;

[0040] Examples 5-8, heat treatment and annealing at 500°C for 4 hours, after annealing, enter the rolling mill for hot rolling at 500°C, the final rolling temperature is 340°C, and the final thickness of hot rolling is 5mm; the annealing before cold rolling, the annealing temperature is 380°C, the time 4h;

[0041] In step (3):

[0042] Examples 1-4, the annealing time at 200°C is 2.5h; the pass processing rate of the cold-rolled finished product is 40%, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com