A device and method for preparing superhard and supersmooth tetrahedral carbon films by magnetron sputtering

A technology of magnetron sputtering and tetrahedral carbon, which is applied in sputtering coating, metal material coating process, vacuum evaporation coating, etc., and can solve the problem that magnetron sputtering cannot prepare superhard carbon films and can not be prepared at one time Smooth superhard carbon film and other problems, to achieve the effect of good surface finish

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

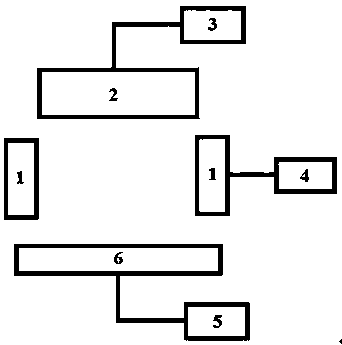

[0030] Such as figure 1 As shown, a device for preparing ultra-hard and ultra-smooth tetrahedral carbon films by magnetron sputtering, the device includes a workpiece disk 6 powered by a bias power supply 5 and a magnetron sputtering target 2 powered by a power supply II3, the magnetron In front of the sputtering target 2 is provided a coil 1 powered by a power supply III4.

[0031] Coil 1 is 5cm high and has 1800 turns.

[0032] Both the bias power supply 5 and the power supply II 3 are DC power supply, AC power supply, high frequency, medium frequency pulse power supply, radio frequency power supply or microwave power supply.

[0033] Power supply III4 is a high-power pulse power supply. When the power is turned on, the magnetic field rises instantly, and when the power is not turned on, the magnetic field first rises and then disappears. The strong magnetic field will compress the plasma, increase the collision probability and electron temperature, and make the ionization...

Embodiment 2

[0036] The method for preparing super-hard and ultra-smooth tetrahedral carbon films by magnetron sputtering of the above-mentioned device, the coating material is provided by the magnetron sputtering target 2, and a direct current of 3-10A is provided to the magnetron sputtering target 2, and the sputtered carbon ions are When passing through the electromagnetic field, the transient magnetic field generated by the current with a peak value of 8-12A provided by the high-power pulse is compressed and heated to further ionize the passing carbon ions and particles, and the electron temperature reaches 8-10eV, and the high-energy carbon ions fly to the workpiece Disk 6 is deposited under the action of a DC bias of 100V to obtain a smooth carbon film. The film is prepared by magnetron sputtering without post-processing.

[0037] Prepare superhard and supersmooth pure carbon film on silicon substrate, the specific implementation is as follows:

[0038] 1) Routine cleaning: degreasi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| surface smoothness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com