Method and device for manufacturing compound eye lens

A manufacturing method and a technology of spectacle lenses, which are applied in the photoplate-making process exposure device, glasses/goggles, photoplate-making process of patterned surface, etc., can solve the problems of complex pattern processing and high cost on the surface of glasses, and meet the requirements of popularization, The effect of good quality and low processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

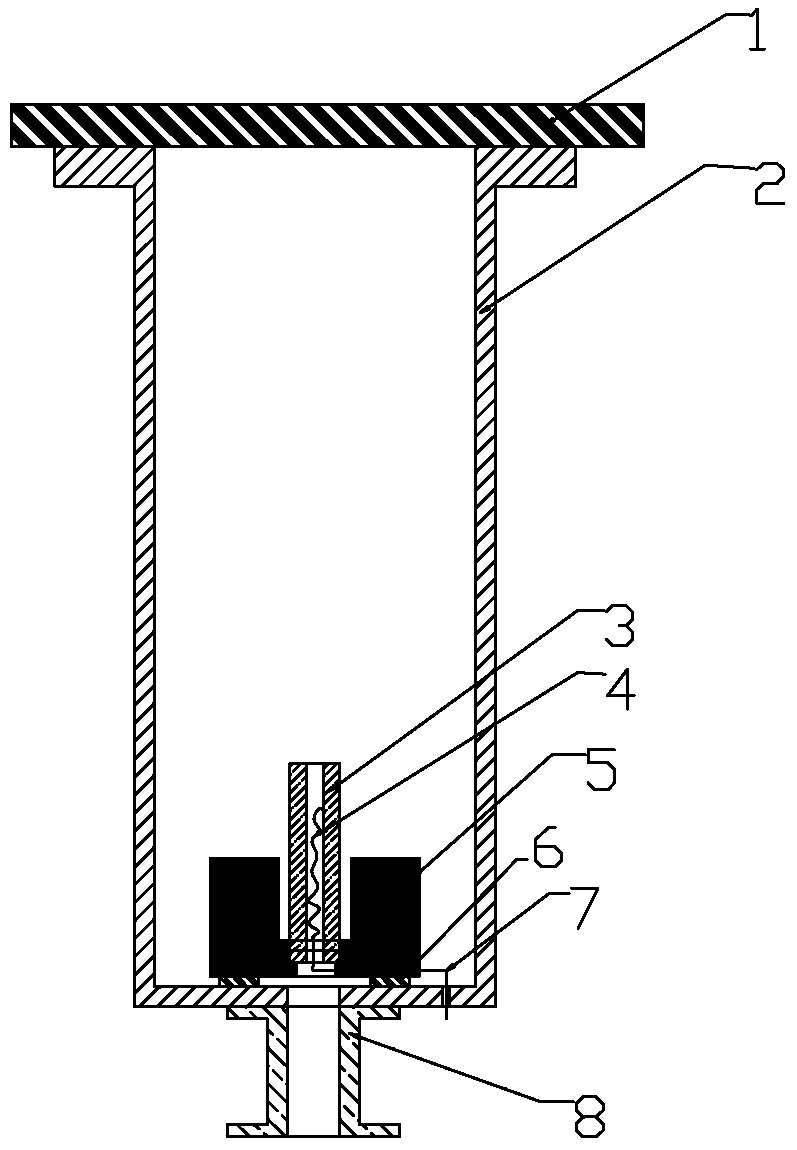

[0024] Such as figure 1 , 3 , as shown in 5.

[0025] A kind of plasma manufacturing method of fly eye lens, it comprises the following steps:

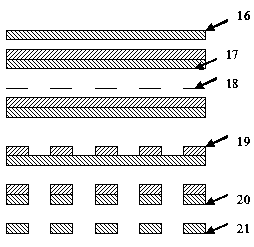

[0026] First, a layer of mask with patterns is formed on the surface of the spectacle lens; the forming process of the mask is as follows: image 3 As shown, first, a layer of photoresist 17 is coated on the mask material 16 such as a metal film material (thickness 100-200 microns) through a treatment process, and the mask 18 is covered on the photoresist 17. A pattern is formed on the resist, and then the metal film and the photoresist are sprayed with a photoresist developer to obtain a photoresist pattern 19, and the etching solution for metal treatment forms a pattern 20 on the metal film, and finally the photoresist is removed to obtain an etching pattern twenty one. This pattern is the mask used for plasma treatment, the top view of the mask is as follows Figure 5 shown.

[0027] Second, place the spectacle lens with the ...

Embodiment 2

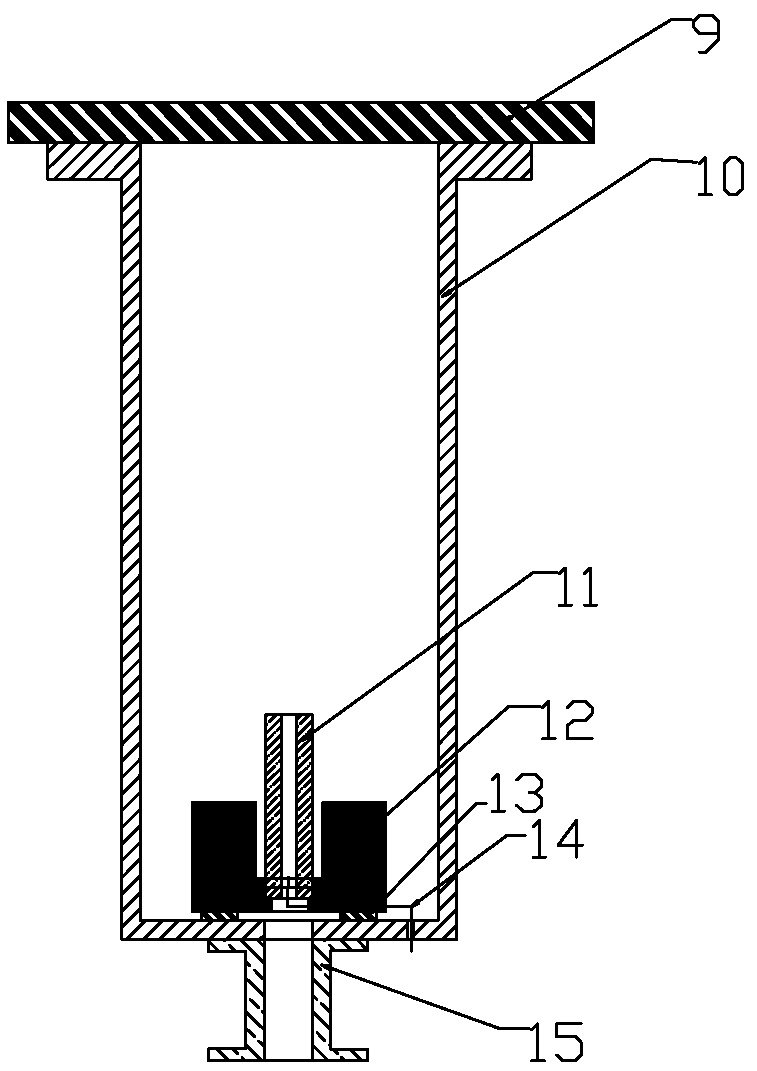

[0029] Such as figure 2 , 3 , 5 shown.

[0030] A method for manufacturing fly eye lenses by ultraviolet irradiation, which comprises the following steps:

[0031] First, a layer of mask with patterns is formed on the surface of the spectacle lens; the forming process of the mask is as follows: image 3 As shown, first, a layer of photoresist 17 is coated on the mask material 16 such as a metal film material (thickness 100-200 microns) through a treatment process, and the mask 18 is covered on the photoresist 17. A pattern is formed on the resist, and then the metal film and the photoresist are sprayed with a photoresist developer to obtain a photoresist pattern 19, and the etching solution for metal treatment forms a pattern 20 on the metal film, and finally the photoresist is removed to obtain an etching pattern twenty one. This pattern is the mask used for ultraviolet irradiation treatment. The top view of the mask is as follows: Figure 5 shown.

[0032] Second, pla...

Embodiment 3

[0034] Such as figure 1 , 4 , 5 shown.

[0035] A kind of plasma manufacturing method of fly eye lens, it comprises the following steps:

[0036] First, on the lens material 22, a layer of photoresist 23 is coated by a process, and the mask 24 of the resist is covered on the photoresist 23, and after ultraviolet irradiation, a pattern is formed on the photoresist, and then the photoresist is passed through Spray the photoresist developer to obtain the photoresist pattern 25, put the photoresist pattern on the lens surface together in plasma or ultraviolet equipment, form a pattern on the lens surface, and finally remove the photoresist to obtain the pattern 26, such as Figure 4 , the figure 26 is the mask used for plasma treatment, the top view is as Figure 5 shown.

[0037] Second, place the spectacle lens with the mask on such as figure 1 Plasma treatment is performed on the shown plasma treatment device, and finally a plasma layer is deposited on the surface of the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com