Double-helix device for recovering heavy metals from sludge by adopting electrochemical removal method

A spiral, electrochemical technology, applied in the field of waste treatment and recycling, can solve the problems of insufficient contact between electrodes and sludge, low electrolysis efficiency, and inability to make full use of current efficiency, achieving both environmental value and economic benefits. , High utilization rate of electric energy, the effect of reducing ion migration distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

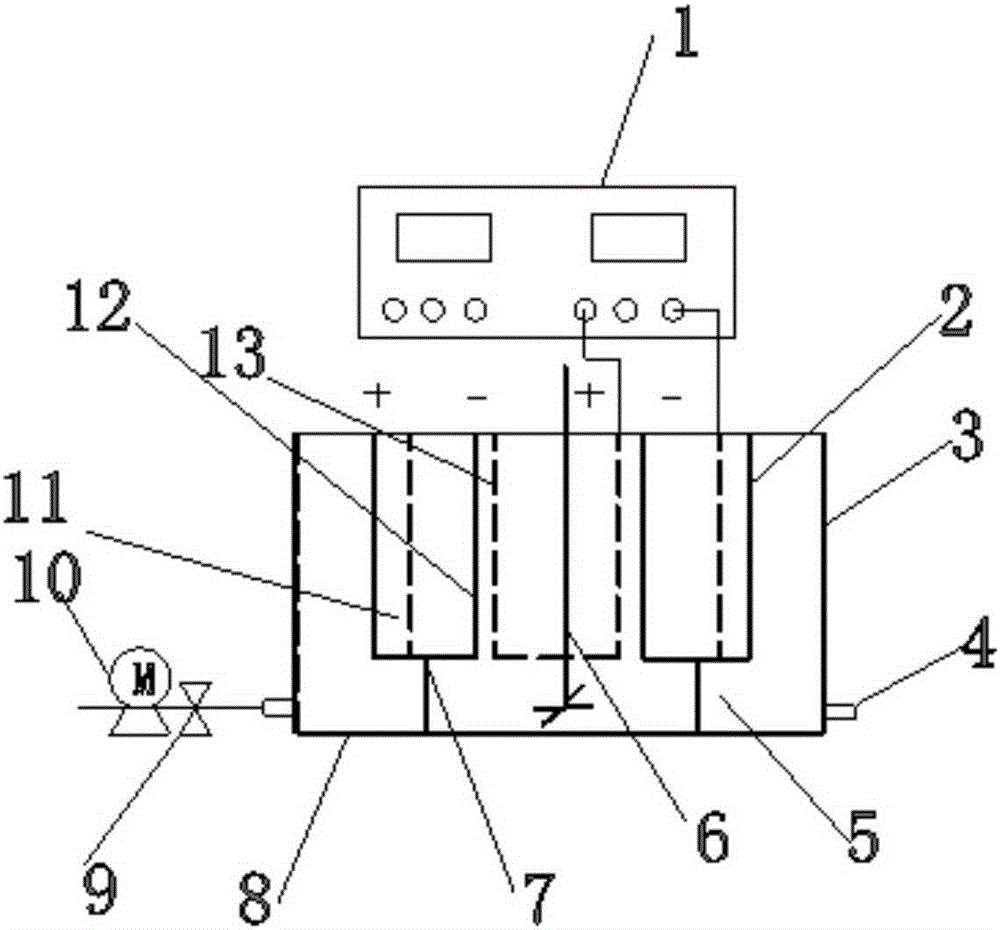

[0018] like figure 1 As shown, a double-layer spiral electrochemical removal and recovery of heavy metals in sludge device, including spiral electrochemical reactor, regulated DC power supply 1, cathode electrode 11, anode electrode 13, mechanical stirrer 6 and ion exchange membrane ;

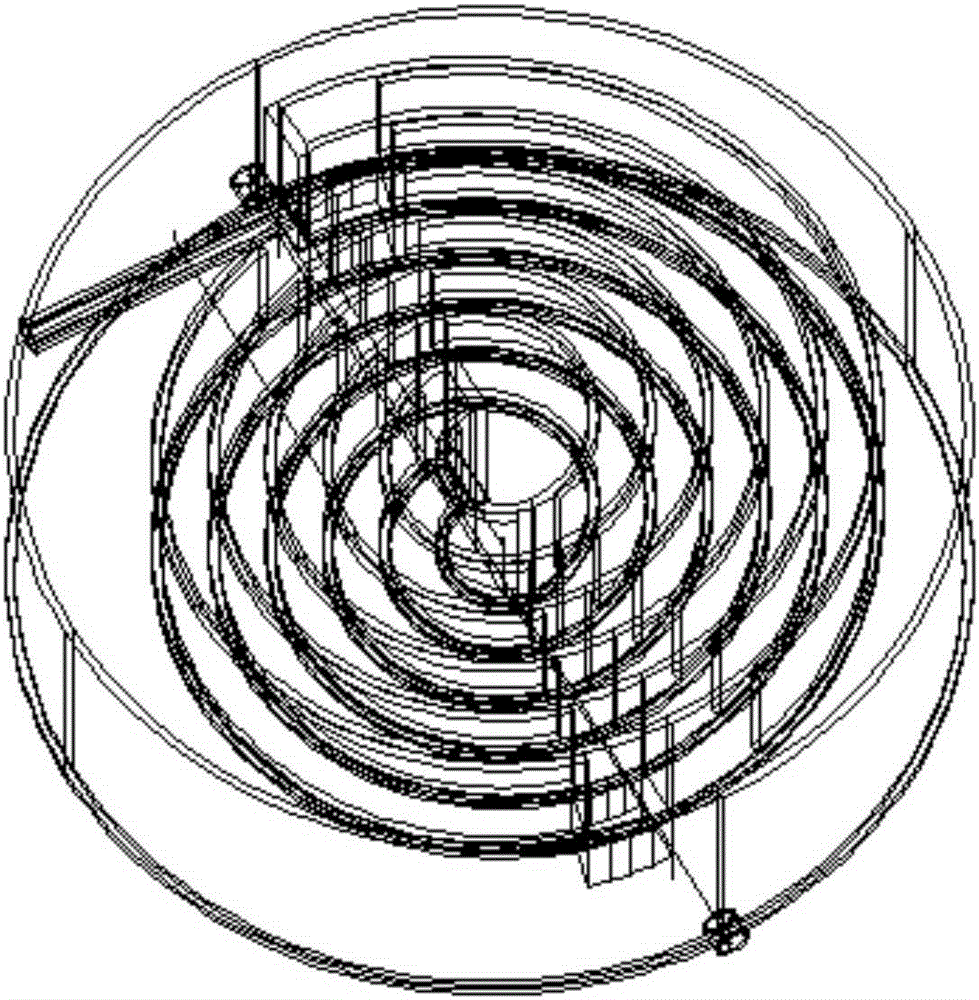

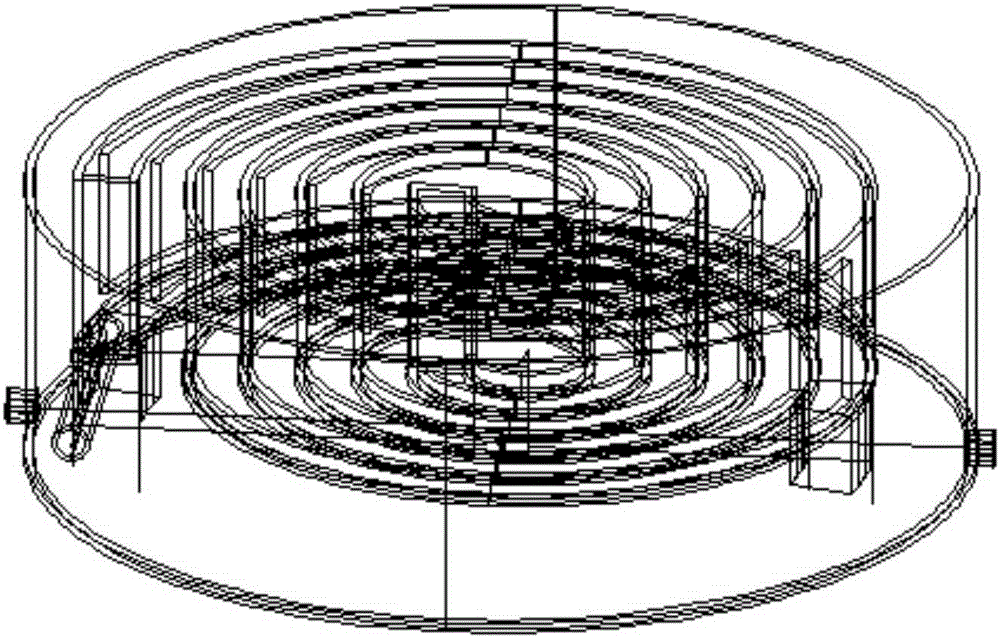

[0019] like figure 2 , 3 , 4, and 5, the described electrochemical reactor is made up of an outer cylinder 3, a middle spiral barrel 2, an inner spiral barrel 12, a circular lower bottom plate 8, a spiral opening upper bottom plate 7 and a support 5; the middle spiral The barrel, the inner spiral barrel and the upper bottom plate of the spiral opening can be disassembled and assembled. Among them, the inner spiral cylinder, the middle spiral cylinder and the spiral opening upper bottom plate are located on the upper layer, surrounded by the outer cylindrical cylinder, and stand on the circular lower bottom plate supported by brackets, forming a double-layer structure. Both the bottom of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com