Preparation method of anti-metal nickel copper zinc ferrite separating magnetic sheet material

A technology of nickel-copper-zinc ferrite and magnetic isolation sheet, which is applied in the field of electronic materials, can solve the problems of reducing material permeability, resource waste environment, and low crystallinity, so as to reduce magnetic domain resonance loss, improve crystallization degree, Effect of Improving Magnetic Permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

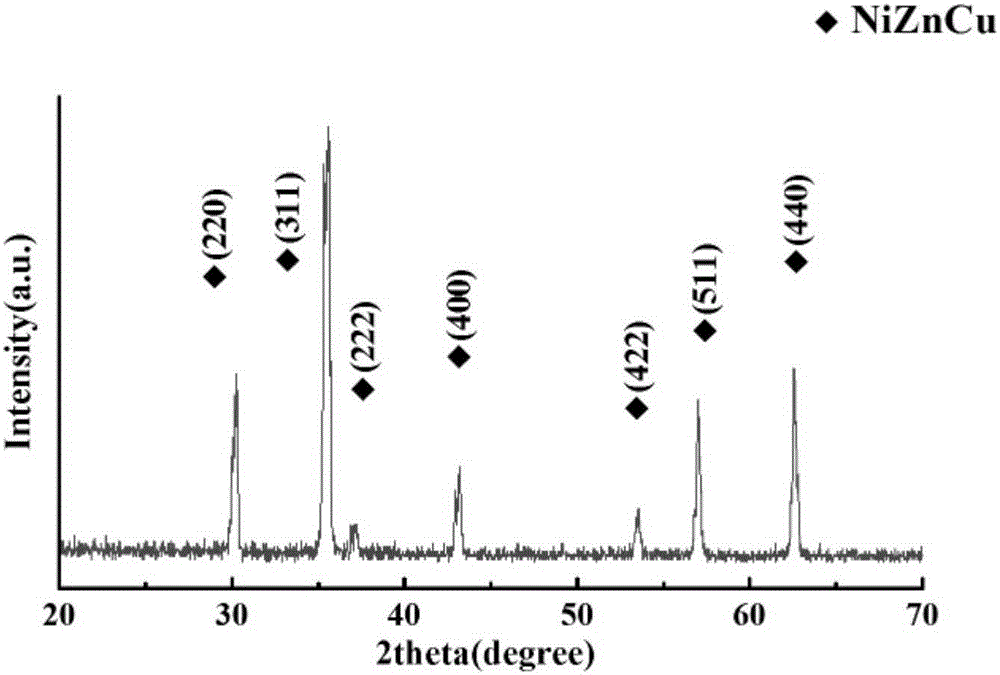

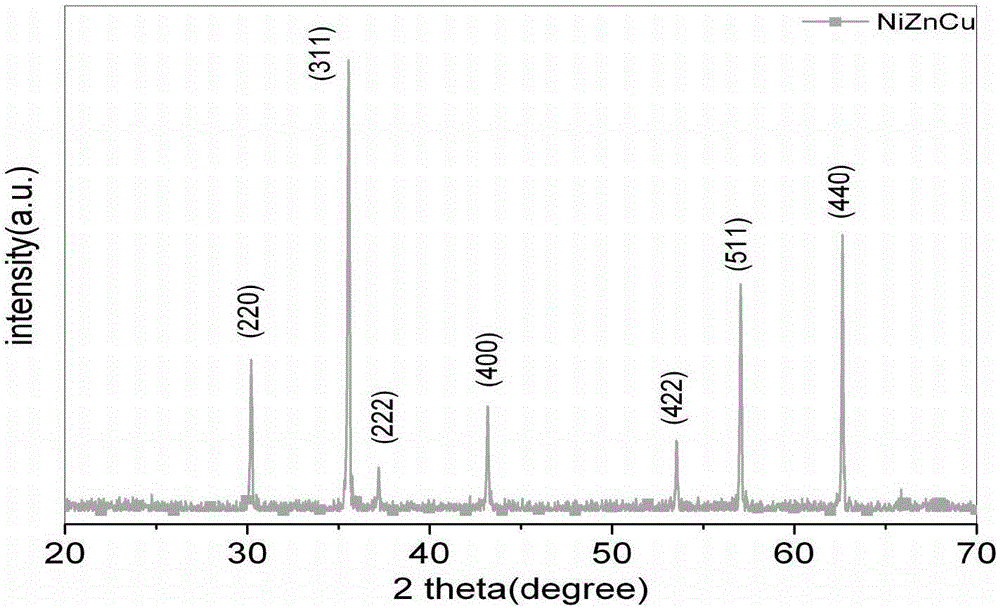

Image

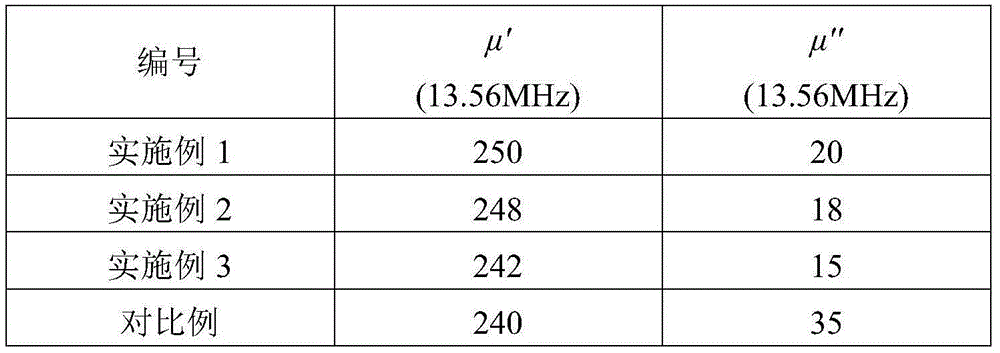

Examples

Embodiment 1

[0032] A method for preparing a metal-resistant nickel-copper-zinc ferrite magnetic isolation sheet material, comprising the following steps:

[0033] Step 1: Weigh the raw materials of the main components in proportion, and the content of the main components in terms of their respective standards is: 49.6mol% Fe 2 o 3 , 16.7mol% NiO, 25.2mol% ZnO, 8.5mol% CuO; the raw materials were ball milled in a planetary ball mill for 2h at a speed of 250r / min, and the mass ratio of raw materials, water and steel balls was 1:1.5:3, of which steel The diameter of the ball is 6.5mm;

[0034] Step 2: Dry the powder obtained in step 1 at 80°C in an oven, grind and pulverize it, and then place it in a sintering container for pre-sintering treatment at a pre-sintering temperature of 850°C and a holding time of 3 hours to obtain a pre-sintered material;

[0035]Step 3: Processing of magnetic fragments: Wash and dry the magnetic fragments, and ball mill them in a planetary ball mill for 10 hou...

Embodiment 2

[0046] The difference between this embodiment and embodiment 1 is that when mixing and ball milling in step 4, the mass percentage of the main component is 80 wt%, and the mass percentage of the magnetic scrap is 20 wt%, and the rest of the steps are the same as in embodiment 1.

Embodiment 3

[0048] The difference between this embodiment and embodiment 1 is that when mixing and ball milling in step 4, the mass percentage of the main component is 71.4 wt%, and the mass percentage of the magnetic fragments is 28.6 wt%, and the rest of the steps are the same as in embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com