Lithium base grease and preparation method of lithium base grease

A lithium-based lubricating grease and lubricating grease technology, applied in lubricating compositions, petroleum industry, etc., can solve the problems of large water leaching loss, poor water resistance, large oil separation of steel mesh, etc., and achieve small water leaching loss , high dropping point, and small oil separation effect on the steel mesh

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

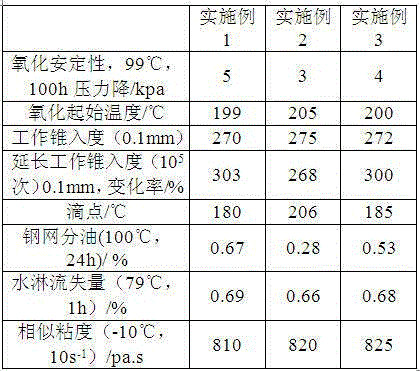

Embodiment 1

[0032] Embodiment 1 A kind of lithium base lubricating grease

[0033] Described lithium base lubricating grease, the mass ratio of each raw material component is:

[0034] 80 parts of base oil, 20 parts of intermediate oil, 2.2 parts of lithium hydroxide, 8 parts of acid for saponification, 1.5 parts of antioxidant, 0.5 parts of additives, 1.5 parts of rust inhibitor, and 9 parts of water.

[0035] The base oil, the model is 60N, the kinematic viscosity (40°C) is 10mm 2 / s, the viscosity index is 94, the flash point is 190°C, and the pour point is -30°C.

[0036] The intermediate oil, model is 250SN, 100 ℃ kinematic viscosity is 8mm 2 / s, the flash point is 230°C, the pour point is -18°C, and the viscosity index is 100.

[0037] The saponification acid includes stearic acid, salicylic acid and boric acid, and the mass ratio is 3:1:1.

[0038] The antioxidant includes 4-hydroxydodecanoic acid anilide, 4,4'-di-tert-octyl diphenylamine, dioctadecyl pentaerythritol diphosphit...

Embodiment 2

[0043] Embodiment 2 A kind of lithium base lubricating grease

[0044] Adopt the raw material described in embodiment 1, only change the raw material composition of lubricating grease, change into:

[0045] Described lithium base lubricating grease, the mass ratio of each raw material component is:

[0046] 81 parts of base oil, 21 parts of intermediate oil, 2.3 parts of lithium hydroxide, 10 parts of acid for saponification, 1.7 parts of antioxidant, 0.6 parts of additives, 1.6 parts of rust inhibitor, and 11 parts of water.

Embodiment 3

[0047] Embodiment 3 A kind of lithium base lubricating grease

[0048] Adopt the raw material described in embodiment 1, only change the raw material composition of lubricating grease, change into:

[0049] Described lithium base lubricating grease, the mass ratio of each raw material component is:

[0050] 83 parts of base oil, 25 parts of intermediate oil, 2.5 parts of lithium hydroxide, 11 parts of acid for saponification, 1.8 parts of antioxidant, 0.9 parts of additives, 1.9 parts of rust inhibitor, and 12 parts of water.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| drop melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com