High-strength titanium diboride particle-reinforced copper-based composite material and preparation method thereof

A technology of copper-based composite materials and titanium diboride, which is applied in the field of high-strength titanium diboride particle-reinforced copper-based composite materials, can solve the problems of heavy equipment application restrictions, and achieve the effects of high hardness, increased strength, and high melting point

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

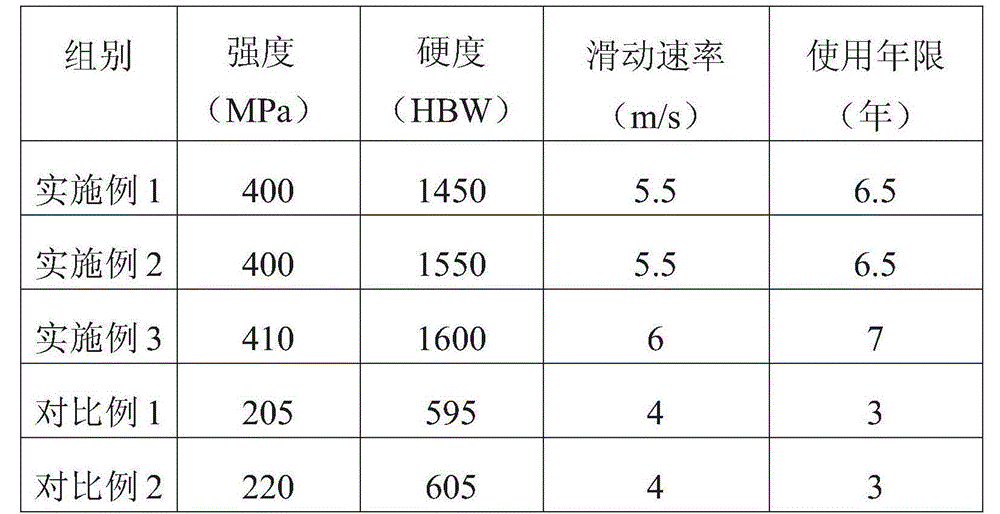

Examples

Embodiment 1

[0027] The high-strength titanium diboride particle-reinforced copper-based composite material for heavy equipment in Example 1 of the present invention is composed of the following components in volume percentage: 6% of high-purity titanium diboride with a purity>98%, copper alloy ZCuSn 5 Zn 5 Pb 5 94% where the copper alloy ZCuSn 5 Zn 5 Pb 5 It consists of the following components by mass percentage: tin ingot 4.0-6.0%, zinc 4.0-6.0%, lead ingot 4.0-6.0%, nickel ≤ 3.0%, impurities ≤ 1.0%, and the rest is copper.

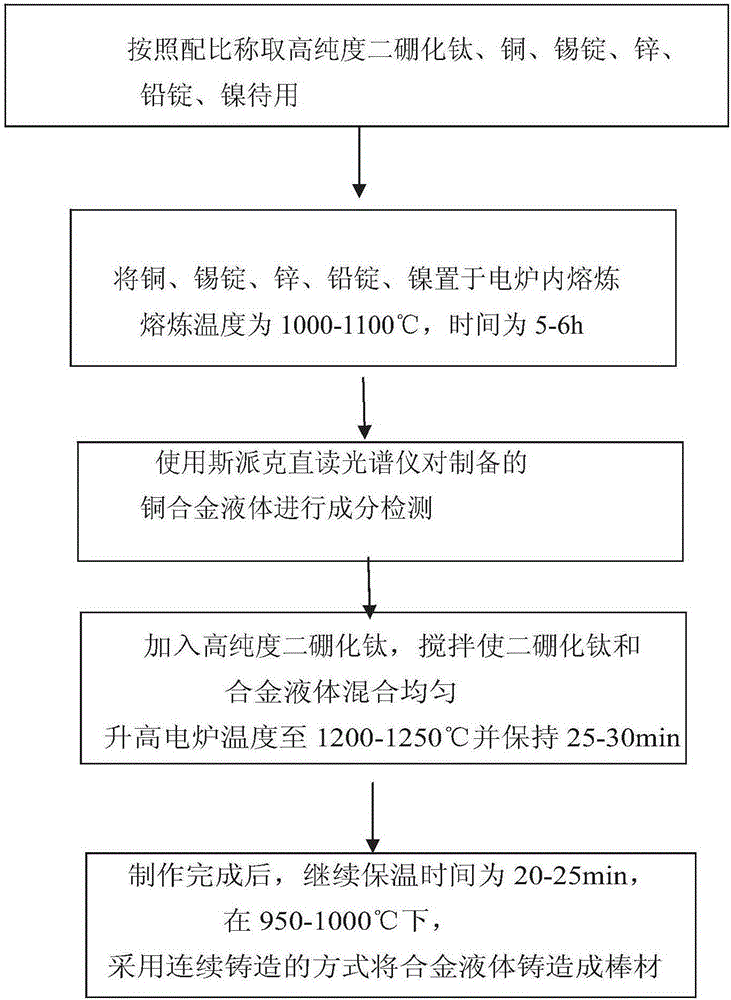

[0028] The preparation method of the high-strength titanium diboride particle reinforced copper-based composite material used for heavy equipment in Example 1 of the present invention has the following steps (such as figure 1 shown):

[0029] 1) Preparation of copper alloy ZCuSn 5 Zn 5 Pb 5 , putting electrolytic copper, tin ingots, zinc, lead ingots, and nickel into an electric furnace for melting according to the above weight ratios, the volume of the cop...

Embodiment 2

[0035] The high-strength titanium diboride particle-reinforced copper-based composite material for heavy equipment in Example 2 of the present invention is composed of the following components in volume percentage: 7% of high-purity titanium diboride with a purity>98%, copper alloy ZCuSn 5 Zn 5 Pb 5 93% where the copper alloy ZCuSn 5 Zn 5 Pb 5 It consists of the following components by mass percentage: tin ingot 4.0-6.0%, zinc 4.0-6.0%, lead ingot 4.0-6.0%, nickel ≤ 3.0%, impurities ≤ 1.0%, and the rest is copper.

[0036] The preparation method of the high-strength titanium diboride particle reinforced copper-based composite material used for heavy equipment in Example 2 of the present invention has the following steps (such as figure 1 shown):

[0037] 1) Preparation of copper alloy ZCuSn 5 Zn 5 Pb 5 , put electrolytic copper, tin ingots, zinc, lead ingots, and nickel into the electric furnace for melting according to the above weight ratio, the copper alloy liquid v...

Embodiment 3

[0043] The high-strength titanium diboride particle-reinforced copper-based composite material for heavy equipment in Example 3 of the present invention is composed of the following components in volume percentage: 9% of high-purity titanium diboride with a purity>98%, copper alloy ZCuSn 5 Zn 5 Pb 5 91% where the copper alloy ZCuSn 5 Zn 5 Pb 5 It consists of the following components by mass percentage: tin ingot 4.0-6.0%, zinc 4.0-6.0%, lead ingot 4.0-6.0%, nickel ≤ 3.0%, impurities ≤ 1.0%, and the rest is copper.

[0044] The preparation method of the high-strength titanium diboride particle reinforced copper-based composite material used for heavy equipment in Example 3 of the present invention has the following steps (such as figure 1 shown):

[0045] 1) Preparation of copper alloy ZCuSn 5 Zn 5 Pb 5 , putting electrolytic copper, tin ingots, zinc, lead ingots, and nickel into the electric furnace for melting according to the above weight ratio, the copper alloy liqu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| percent by volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com