A basket-type x-ray machine for measuring the cutting height of waste lead-acid batteries

A technology of lead-acid battery and X-ray machine, which is applied in the field of waste material recycling and processing, can solve the problems of complicated determination of division point, great manpower and material resources, and inability to distinguish cutting height, etc., so as to save manpower determination cost and reduce separation Difficulty, cutting height measurement work is convenient and direct effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

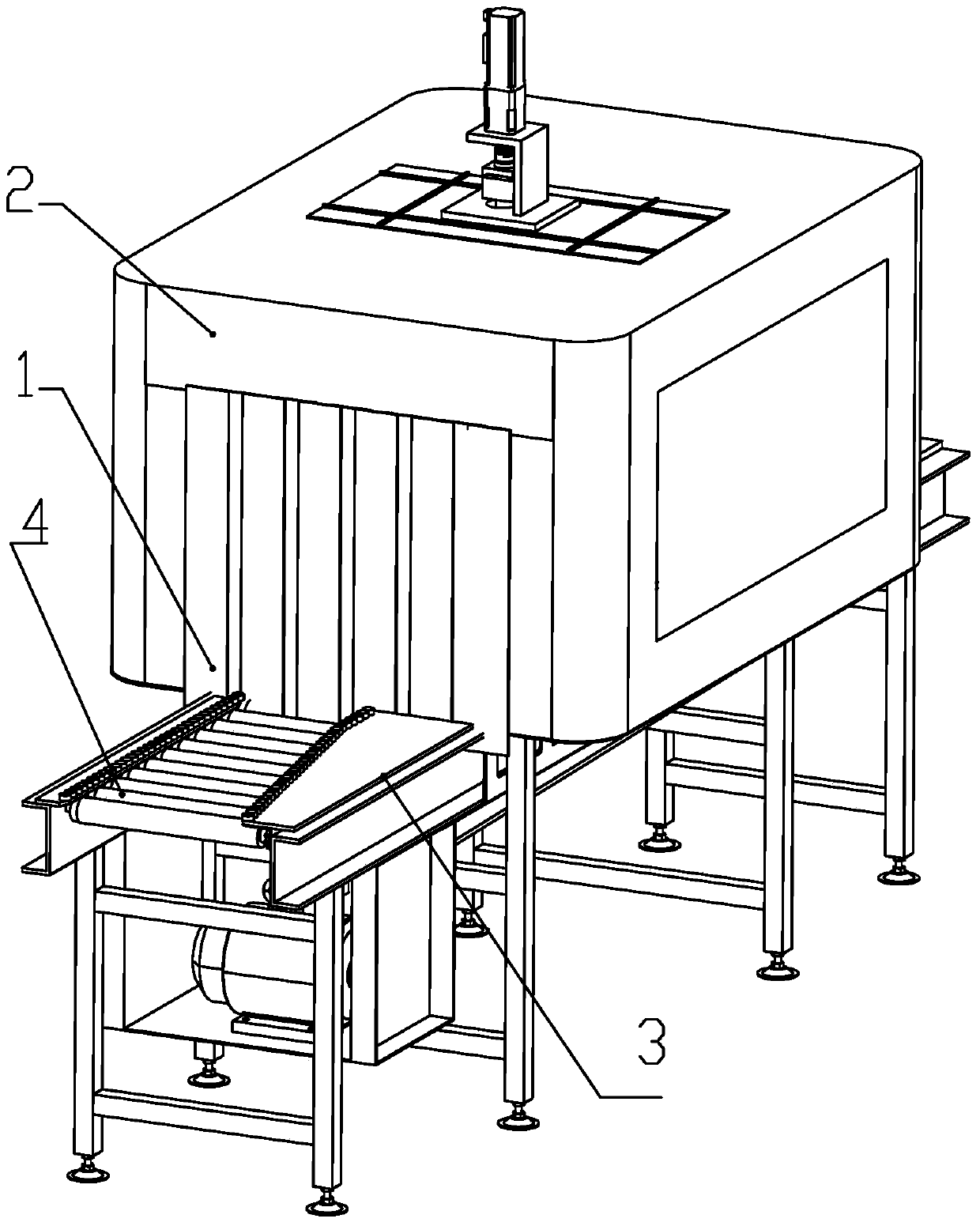

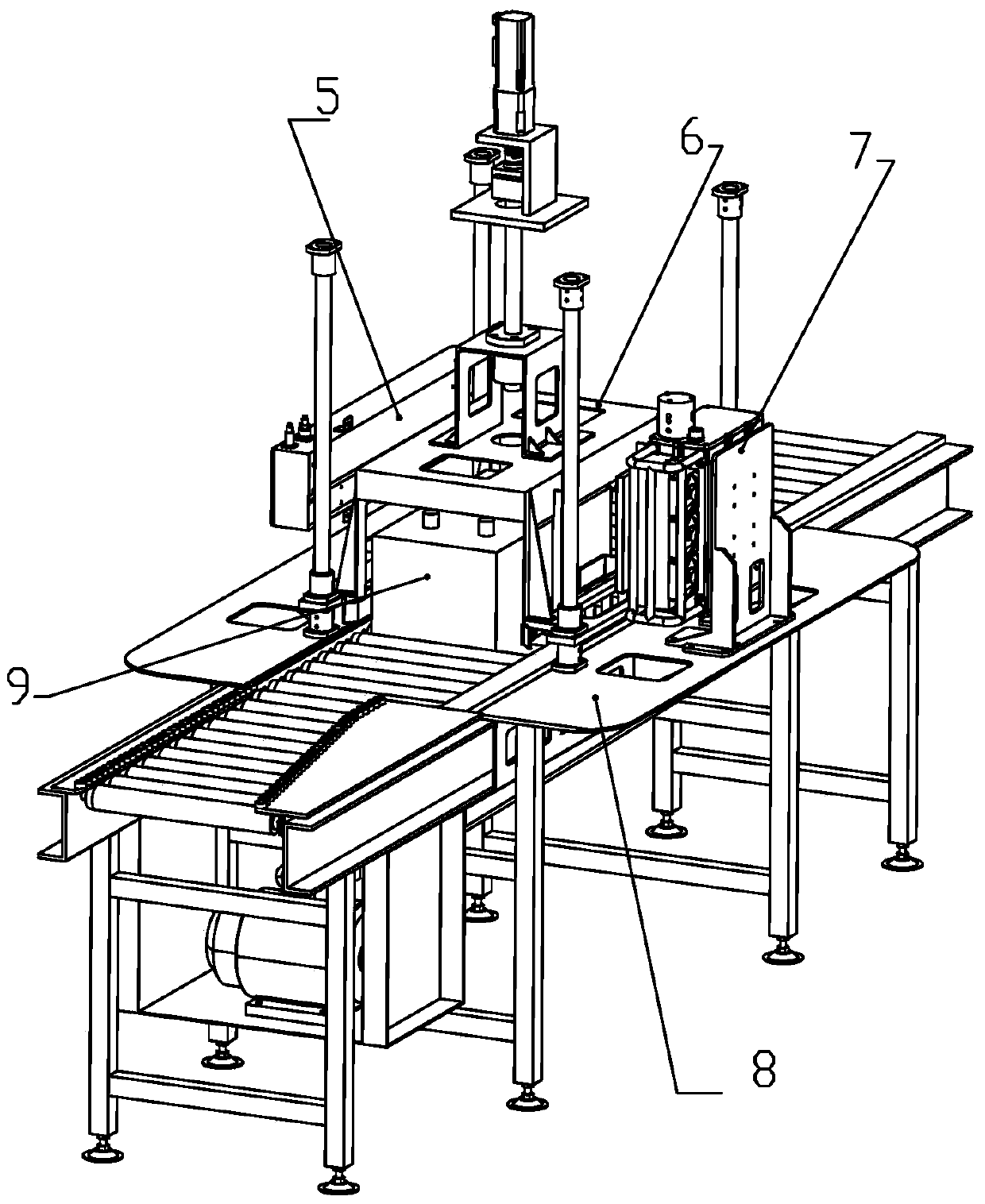

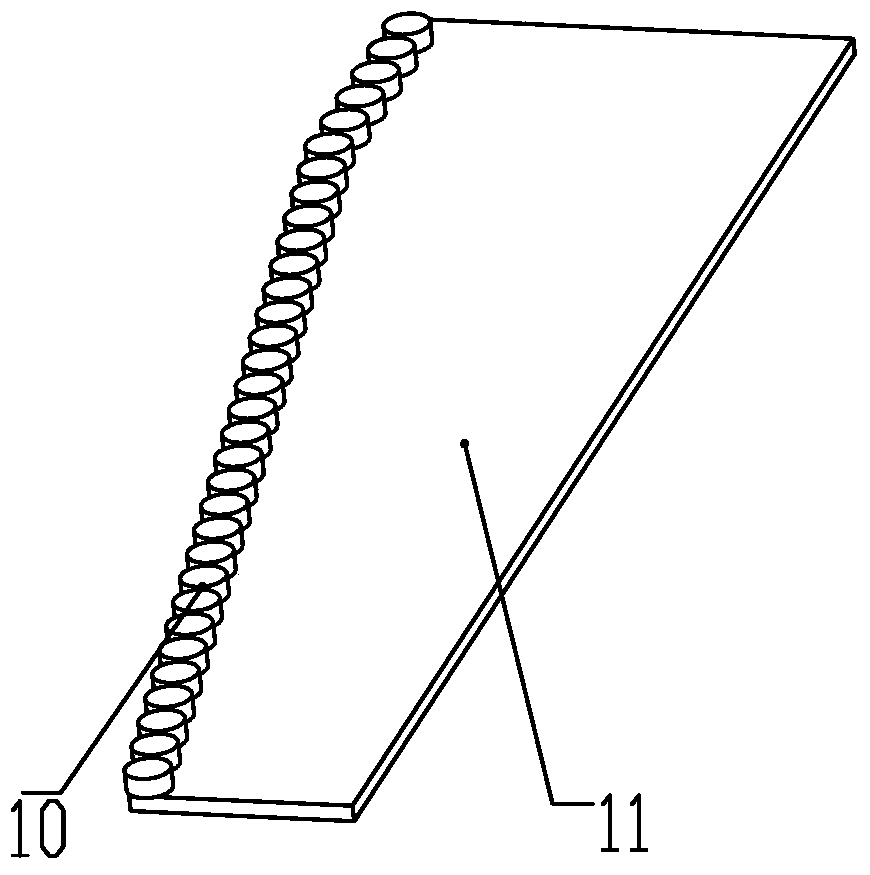

[0033] According to the implementation of the present invention, the basket-type X-ray machine used for the measurement of the cutting height of waste lead-acid batteries is as follows: Figure 1-9 As shown, it mainly includes: a roller conveyor 4 , a lead plate casing 2 , a lead curtain 1 , a linear array detector 5 , a lifting basket device 6 , and an X-ray source 7 . A lead sheet casing 2 is installed in the middle above the roller surface of the roller conveyor 4; along the transmission direction of the roller surface of the roller conveyor 4, lead curtains 1 are installed at the inlet and outlet positions of the lead sheet casing 2; inside the lead sheet casing 2 X-ray source 7 and line array detector 5 are respectively installed on both horizontal sides perpendicular to the direction of entrance and exit, and a lifting basket device for accommodating lead-acid batteries is installed between X-ray source 7 and line array detector 5 6. U-shaped frame stoppers 38 and U-shap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com