Bi-functional adsorption rotating wheel achieving dehumidifying and VOCs removing

A dual-function, rotary wheel technology, applied to the separation of dispersed particles, air quality improvement, chemical instruments and methods, etc., can solve the problems of increasing costs, occupying space, increasing costs, etc., to save equipment space and reduce space occupation , to ensure the effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

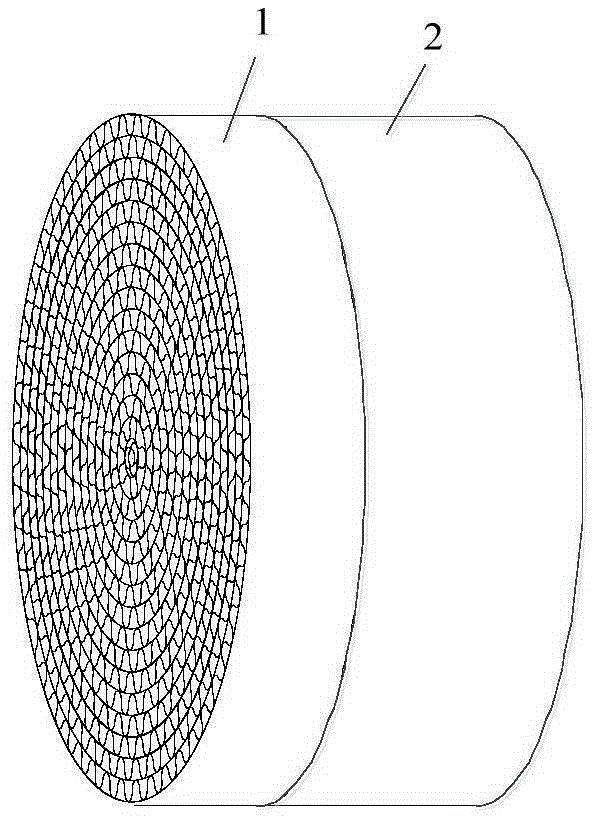

[0046] The method for preparing the dual-function adsorption runner with the above two runner structures specifically includes the following steps:

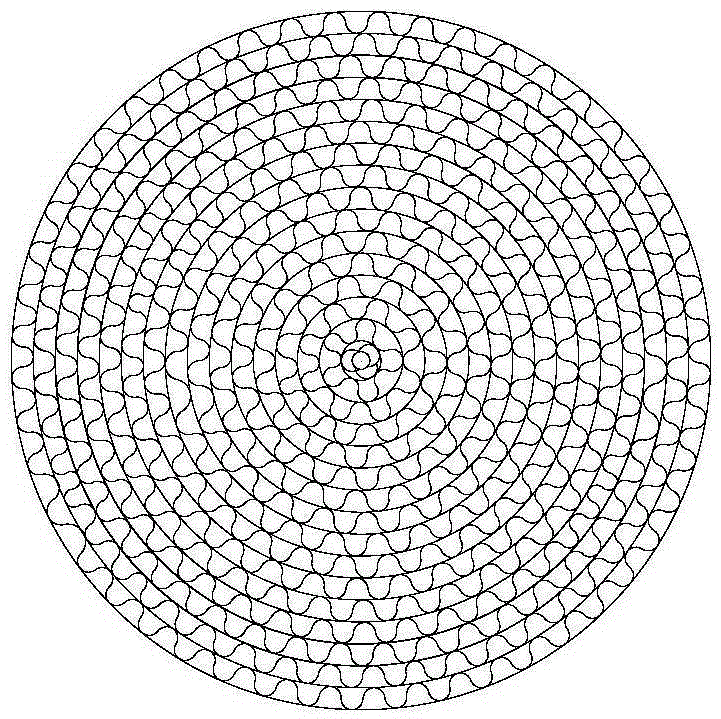

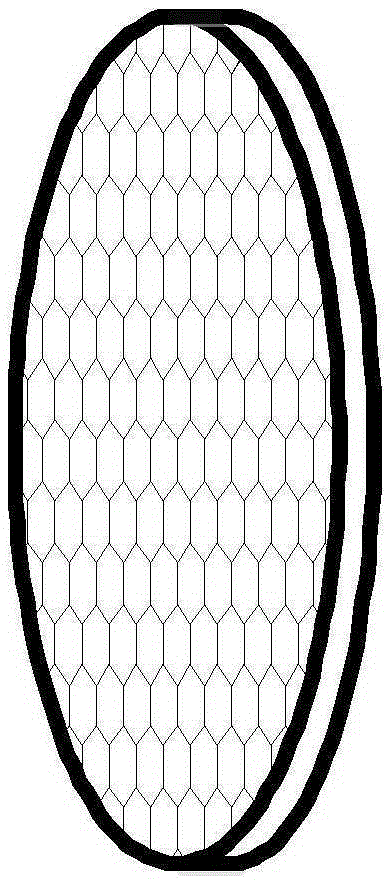

[0047] The first step is to use fiber material to make two porous honeycomb structure carriers, which are used as two runners for backup. The fiber material can be one or more of ceramic fiber, glass fiber, activated carbon fiber, and synthetic fiber. mixture;

[0048] Step 2. Mix 0.1-50 parts by weight of adsorbent molecular sieve, 0.1-50 parts of dehumidifier molecular sieve, respectively, with 0.1-80 parts of inorganic binder such as silica sol or aluminum sol, and 0.1-300 parts of water. , Respectively make adsorbent slurry and desiccant slurry;

[0049] Step 3: Choose dipping, spraying or rinsing to load the adsorbent slurry evenly on one of the runners, and load the dehumidifier slurry evenly on the other runner;

[0050] Step 4: Drying with hot air or microwave for 0.1-24 hours, and docking two runners to obtain a dual-function c...

Embodiment 1

[0064] Combine Figure 5 As shown, the VOCs exhaust gas 6 with a certain moisture content preferentially enters the dehumidification zone 1, the moisture in the exhaust gas is removed and then enters the molecular sieve runner adsorption zone 2, and the VOCs exhaust gas is adsorbed to obtain purified gas 9. In this process, the thickness ratio and total thickness of the dehumidification runner and the molecular sieve runner are designed and adjusted according to the moisture content of the exhaust gas and the site conditions, and various parameters are adjusted in time according to the operating conditions. When the adsorption is saturated, it enters the desorption zone. The air 3 and the outlet gas 7 of the cooling zone are heated by the electric heating device 8 to obtain high-temperature air with a temperature of 100-300℃. The molecular sieve runner is preferentially desorbed, and the high-temperature air passes After the molecular sieve runner, the temperature drops to 80-15...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com