Cable sheath tube preparation method

A cable sheathing and sheathing technology, which is applied to insulated cables, cables, circuits, etc., can solve problems such as unsatisfactory, and achieve the effects of strong flame retardant performance, reduced production costs, and reduced environmental pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A high-flame-retardant and high-strength cable, which includes a core, an insulating layer, an inner sheath, and a sheath tube from the inside to the outside. The raw materials for the sheath tube, in parts by weight, include:

[0039] Ethylene-octene copolymer (Foshan Jinzeqiang Plastic Materials Co., Ltd. ENGAG8003) 90 copies

[0040] 5 parts of plant ash

[0041] 3 parts gum

[0042] 0.8 parts of butadienyl triethoxysilane

[0043] 2 parts stearic acid

[0044] 0.8 parts of white carbon black

[0045] 5 parts of electrolytic zinc acid leaching residue;

[0046] Preparation method: including the following steps:

[0047] (1) Melt blending: mix polyolefin, plant ash, silane coupling agent, stearic acid, and electrolytic zinc acid leaching residue in the above proportions, stir at 600r / min for 10min, and then melt and blend for 10min at 170℃ , Get the rubber;

[0048] (2) Cross-linking: After cross-linking the rubber compound obtained in step (1) at 170° C. for 30 minutes, add gum an...

Embodiment 2

[0053] A high-flame-retardant and high-strength cable, which includes a core, an insulating layer, an inner sheath, and a sheath tube from the inside to the outside. The raw materials for the sheath tube, in parts by weight, include:

[0054] Ethylene-octene copolymer (Foshan Jinzeqiang Plastic Materials Co., Ltd. ENGAG8003) 80 copies

[0055] 2 parts of plant ash

[0056] 1 part gum

[0057] 0.5 part of butadienyl triethoxy silane

[0058] 1 part stearic acid

[0059] 0.6 parts of white carbon black

[0060] 3 parts of electrolytic zinc acid leaching residue;

[0061] Preparation method: including the following steps:

[0062] (1) Melt blending: mix polyolefin, plant ash, silane coupling agent, stearic acid, and electrolytic zinc acid leaching residue in the above proportions, stir at 600r / min for 10min, and then melt and blend for 10min at 170℃ , Get the rubber;

[0063] (2) Cross-linking: After cross-linking the rubber compound obtained in step (1) at 170° C. for 30 minutes, add gum and ...

Embodiment 3

[0068] A high-flame-retardant and high-strength cable, which includes a core, an insulating layer, an inner sheath, and a sheath tube from the inside to the outside. The raw materials for the sheath tube, in parts by weight, include:

[0069] Ethylene-octene copolymer (Foshan Jinzeqiang Plastic Materials Co., Ltd. ENGAG8003) 85 copies

[0070] 3 parts of plant ash

[0071] 2 parts gum

[0072] 0.6 parts of butadienyl triethoxysilane

[0073] 1.5 parts of stearic acid

[0074] 0.7 parts of white carbon black

[0075] 4 parts of electrolytic zinc acid leaching residue;

[0076] Preparation method: including the following steps:

[0077] (1) Melt blending: mix polyolefin, plant ash, silane coupling agent, stearic acid, and electrolytic zinc acid leaching residue in the above proportions, stir at 600r / min for 10min, and then melt and blend for 10min at 170℃ , Get the rubber;

[0078] (2) Cross-linking: After cross-linking the rubber compound obtained in step (1) at 170° C. for 30 minutes, add g...

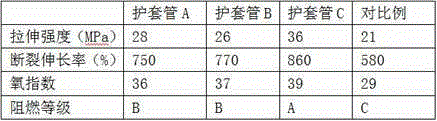

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com