Anti-stain clear varnish and preparation method thereof

A transparent varnish and stain-resistant technology, which is applied to biocide-containing paints, anti-fouling/underwater coatings, wax coatings, etc., can solve the problems of low stain resistance and stains that cannot be easily cleaned, and achieve a fine and smooth paint film. High cost performance, good water and alkali resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

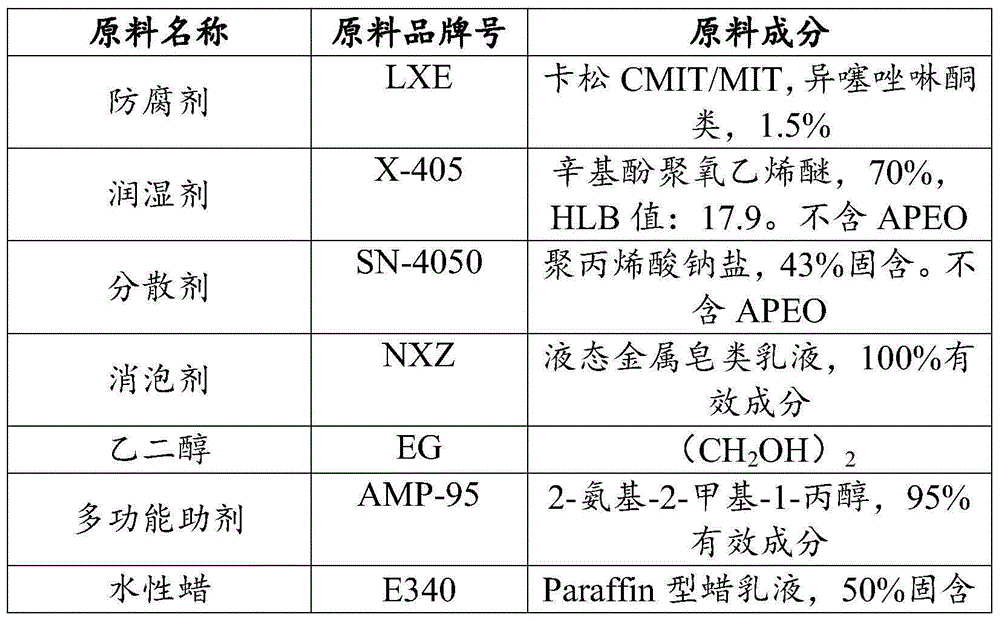

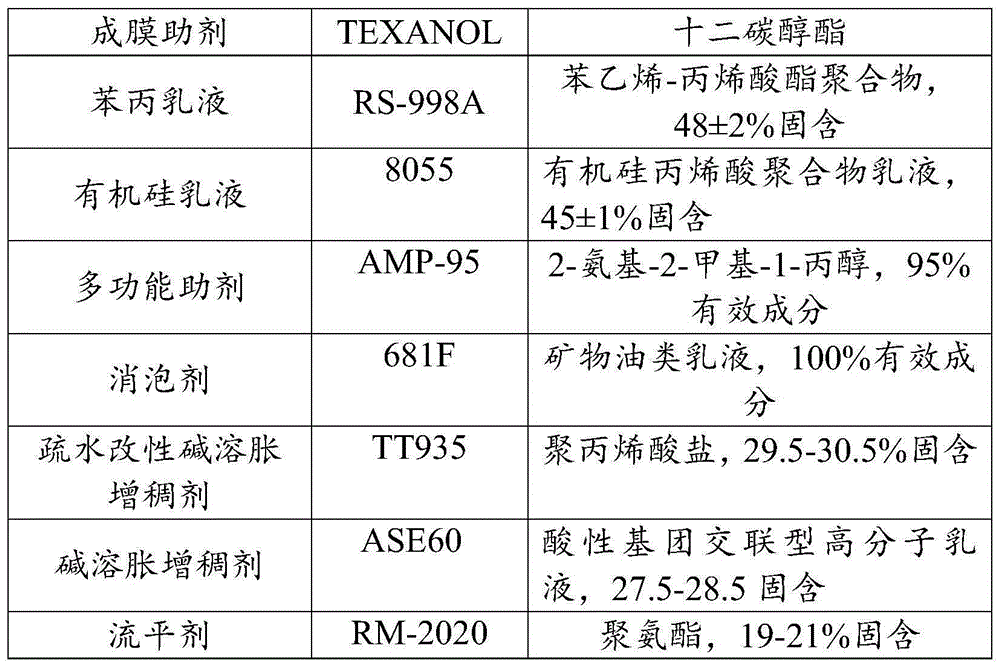

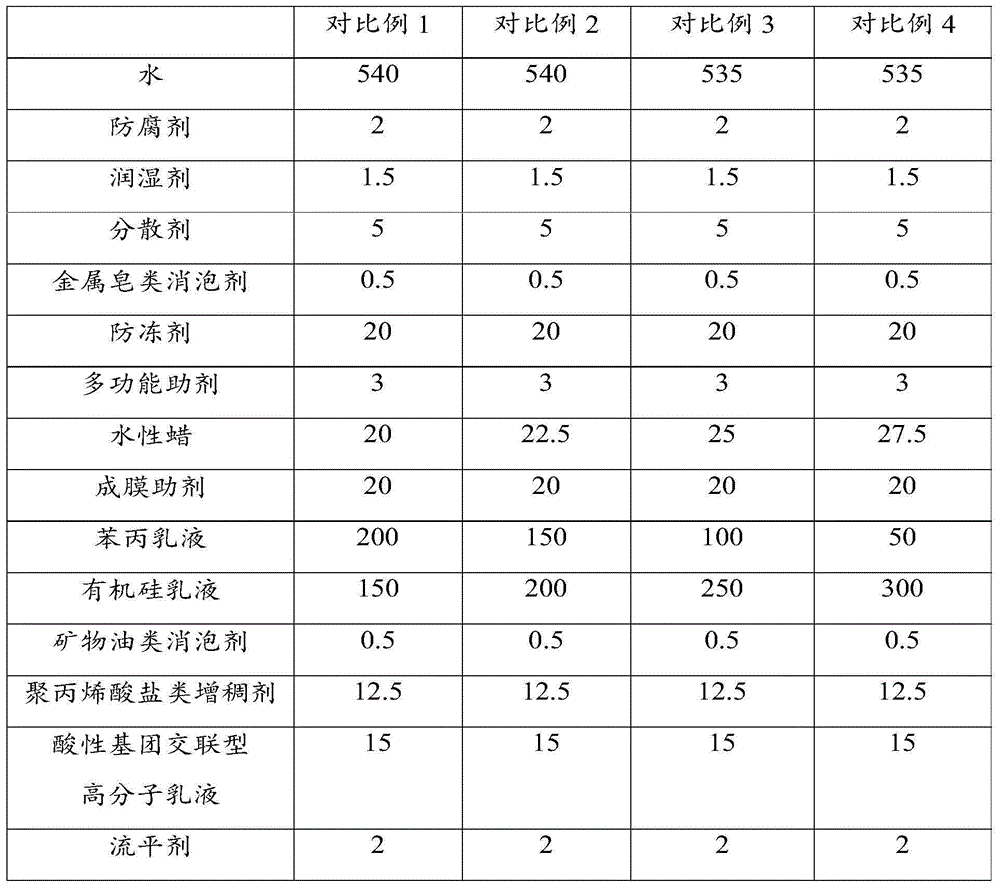

[0033] A kind of transparent varnish provided in this embodiment is mainly prepared from the following components:

[0034] Emulsion: styrene-acrylic emulsion 50kg and silicone emulsion 300kg, additives 80kg (including preservative 2512kg, wetting agent 15002kg, dispersant 32004kg, metal soap defoamer NXZ1kg, antifreeze agent propylene glycol 15kg, multifunctional additive TCP-953kg , film-forming aid Texnol20kg, mineral oil defoamer 681F1kg, thickener HEC620kg and leveling agent RM-20202kg), water-based wax 30kg and water 500kg.

[0035] Its preparation method comprises the following steps:

[0036] At a stirring speed of 350r / min, disperse preservatives, wetting agents, dispersants, metal soap defoamers, antifreeze and two-thirds of multifunctional additives into water. Stir at a certain stirring rate until all dissolve;

[0037] Adjust the stirring rate to 600r / min, add water-based wax, and disperse evenly, then add film-forming aids, emulsion, remaining multi-functional ...

Embodiment 2

[0039] A kind of transparent varnish provided in this embodiment is mainly prepared from the following components:

[0040] Emulsion: styrene-acrylic emulsion 100kg and silicone emulsion 300kg, additives 90kg (including preservative LXE 2kg, wetting agent X-4054kg, dispersant SN-40505kg, metal soap defoamer NXZ1kg, antifreeze agent ethylene glycol 20kg, more Functional additive AMP-953kg, film-forming additive Texnol 20kg, mineral oil defoamer 681F1kg, thickener including: TT93515kg and ASE6015kg, leveling agent RM-20204kg), water-based wax 40kg and water 530kg.

[0041] Its preparation method comprises the following steps:

[0042] At a stirring speed of 300r / min, disperse preservatives, wetting agents, dispersants, metal soap defoamers, antifreeze agents and two-thirds of multifunctional additives into water, after adding all Stir at a certain stirring rate until all dissolve;

[0043] Adjust the stirring rate to 500r / min, add water-based wax, and after dispersing evenly, ad...

Embodiment 3

[0045] A kind of transparent varnish provided in this embodiment is mainly prepared from the following components:

[0046] Emulsion: silicone emulsion 360kg, additives 85kg (including preservative LXE 2kg, wetting agent X-4052kg, dispersant SN-40505kg, metal soap defoamer NXZ0.5kg, antifreeze ethylene glycol 15kg, multifunctional additives AMP-953kg, film-forming aid Texnol30kg, mineral oil defoamer 681F1kg, thickeners include: TT93510kg and ASE6015kg, leveling agent RM-20202kg), water-based wax 33kg and water 530kg.

[0047] Its preparation method comprises the following steps:

[0048] At a stirring speed of 300r / min, disperse preservatives, wetting agents, dispersants, metal soap defoamers, antifreeze agents and two-thirds of multifunctional additives into water, after adding all Stir at a certain stirring rate until all dissolve;

[0049] Adjust the stirring rate to 500r / min, add water-based wax, and after dispersing evenly, add film-forming aids, emulsions, remaining m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com