Terylene spinning oil

A technology of spinning oil and polyester, which is applied in the field of polyester spinning oil, which can solve the problems of thermal stability and coefficient of dynamic friction not reaching high-speed spinning, so as to reduce the generation of fuzz, achieve good evenness, Enhance the effect of hugging force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

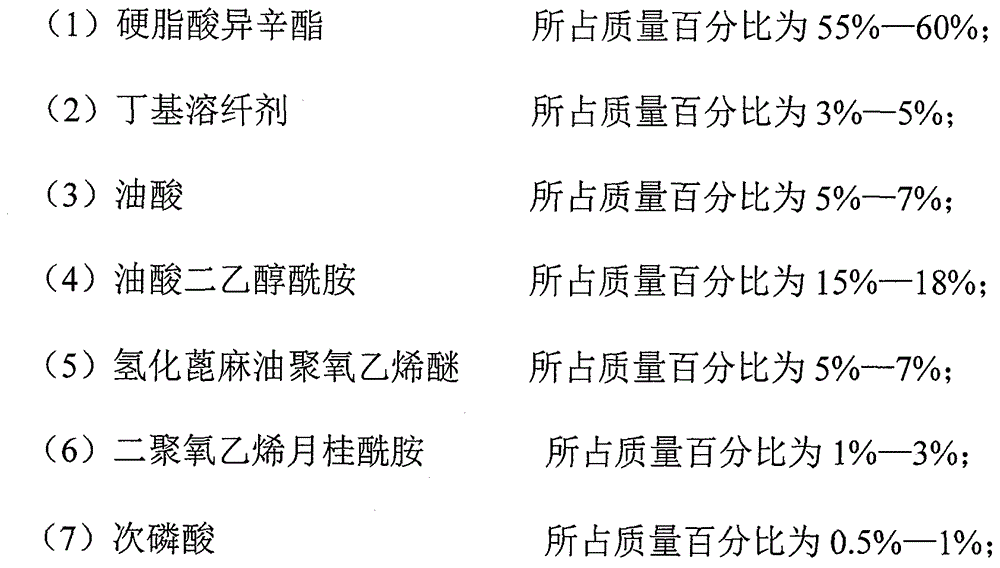

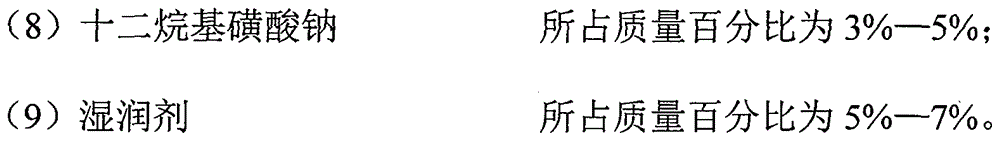

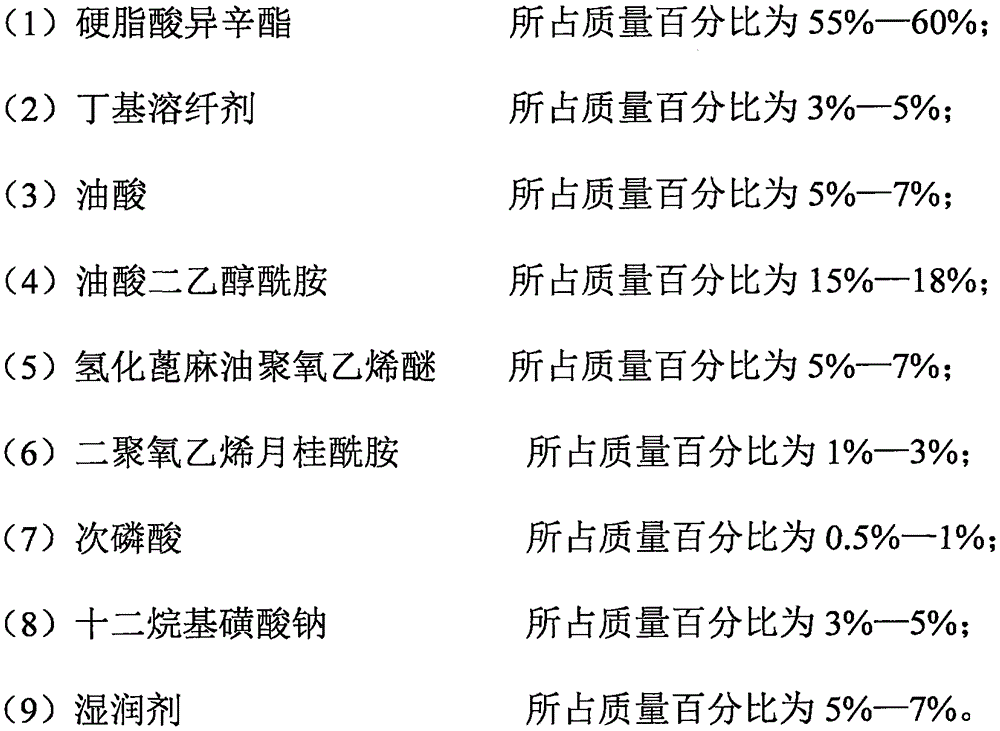

[0015] As an embodiment of the polyester spinning oil of the present invention, the proportion of each component is determined according to the mass percentage in this embodiment: the mass percentage of the isooctyl stearate is 60%; the mass percentage of the butyl cellosolve The percentage is 5%; the mass percentage of oleic acid is 5%; the mass percentage of oleic acid diethanolamide is 18%; the mass percentage of hydrogenated castor oil polyoxyethylene ether is 5%; The mass percentage is 3%; the mass percentage of hypophosphorous acid is 1%; the mass percentage of sodium dodecylsulfonate is 3%; the mass percentage of wetting agent is 5%.

Embodiment 2

[0017] As an embodiment of the polyester spinning oil of the present invention, the proportion of each component is determined according to the mass percentage in this embodiment: the mass percentage of the isooctyl stearate is 55%; the mass percentage of the butyl cellosolve The percentage is 3%; the mass percentage of oleic acid is 7%; the mass percentage of oleic acid diethanolamide is 15%; the mass percentage of hydrogenated castor oil polyoxyethylene ether is 7%; The mass percentage is 1%; the mass percentage of hypophosphorous acid is 0.5%; the mass percentage of sodium dodecylsulfonate is 4.5%; the mass percentage of wetting agent is 7%.

Embodiment 3

[0019] As an embodiment of the polyester spinning oil of the present invention, the proportion of each component is determined according to the mass percentage in this embodiment: the mass percentage of the isooctyl stearate is 57%; the mass percentage of the butyl cellosolve The percentage is 4%; the mass percentage of oleic acid is 6%; the mass percentage of oleic acid diethanolamide is 16%; the mass percentage of hydrogenated castor oil polyoxyethylene ether is 7%; The mass percentage is 1.5%; the mass percentage of hypophosphorous acid is 0.5%; the mass percentage of sodium dodecylsulfonate is 3%; the mass percentage of wetting agent is 5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com