A kind of ohmic contact forming method of sic wafer

A technology of ohmic contact and wafer, which is applied in the direction of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problems of contact metal oxidation, device performance impact, and process complexity in SiC devices, and achieve positive characteristic improvement and removal Effect of carbon residue and simplified treatment process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

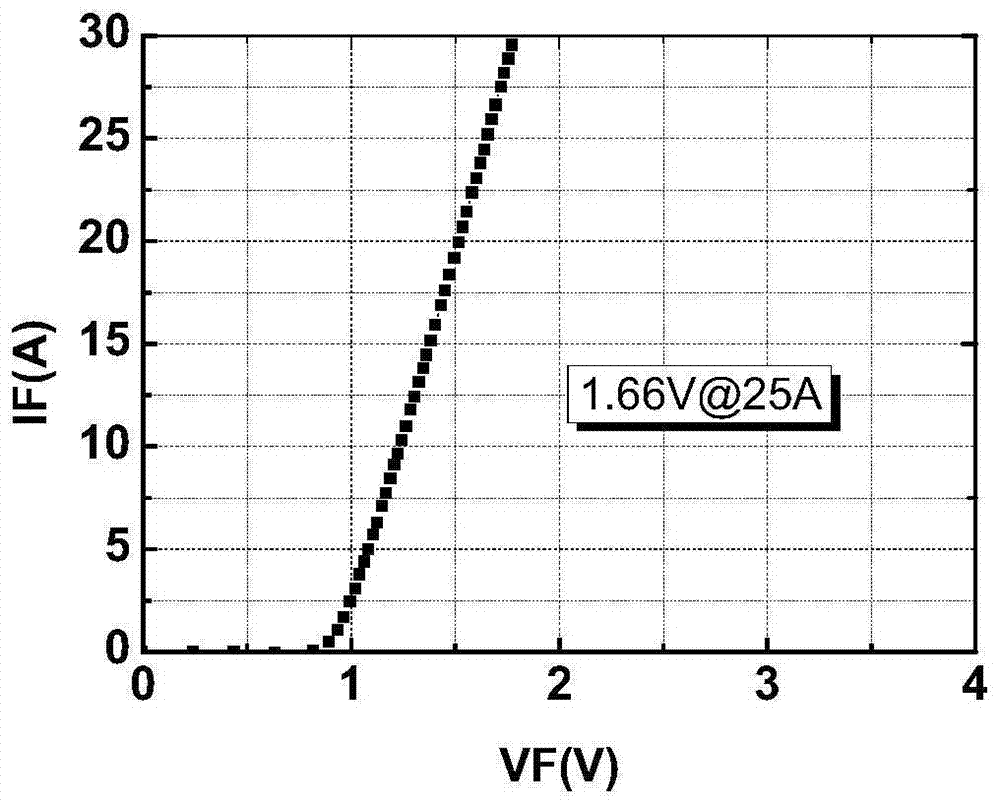

[0041] Fabrication of SiC wafers forming ohmic contacts

[0042] 1) Ohmic contact metal deposition: use magnetron sputtering method to deposit ohmic contact metal on the surface of SiC wafer (4 inches × 400μm), the target material is Ni, the sputtering pressure is set to 0.5 ~ 1Pa, and the magnetron sputtering ends After that, a SiC wafer with a Ni layer of 200-220 nm deposited on the surface is obtained.

[0043] 2) Metal alloying annealing: place the SiC wafer with a Ni layer deposited on the surface in a high-temperature rapid annealing furnace; pass in argon gas, and when the oxygen content monitoring system shows that the oxygen content inside the equipment cavity is less than 20-30ppm, start Heating, the temperature is raised to 950-975°C at a heating rate of 20°C / s, and maintained at this temperature for 5 minutes; the temperature is naturally lowered, and when the temperature drops to 200-300°C, CO is introduced into the annealing furnace 2 gas to fully expose the SiC...

Embodiment 2

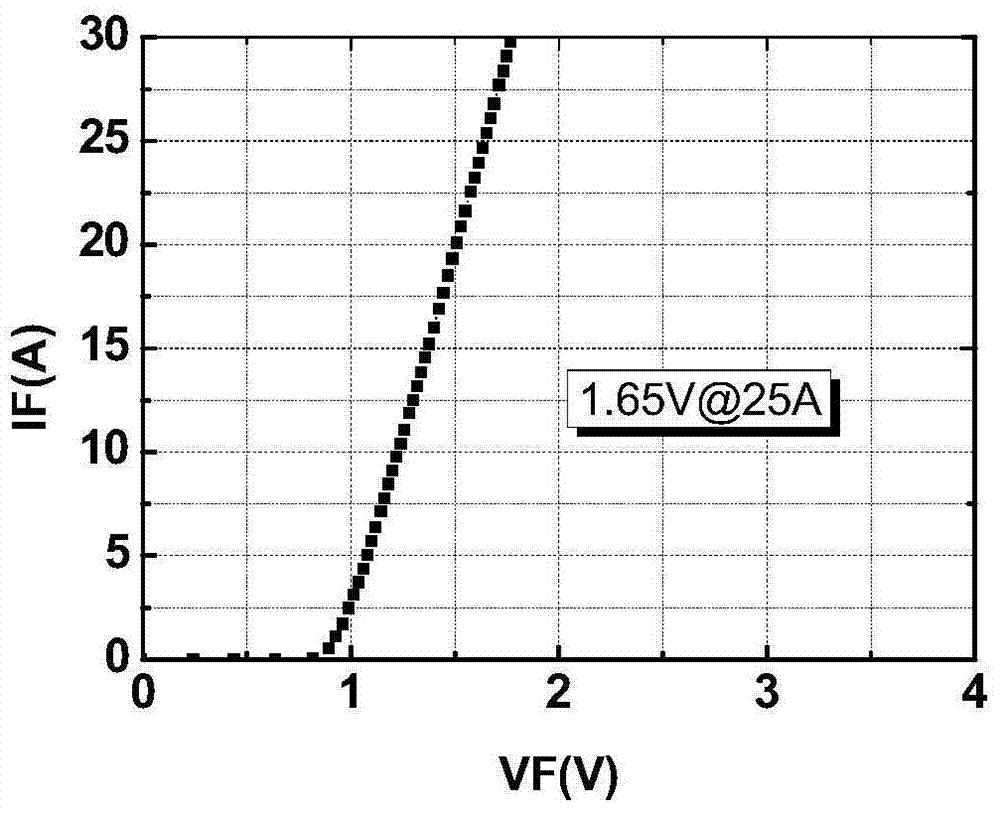

[0045] Fabrication of SiC wafers forming ohmic contacts

[0046] 1) Ohmic contact metal deposition: use magnetron sputtering method to deposit ohmic contact metal on the surface of SiC wafer (4 inches × 400μm), the target material is Ni, the sputtering pressure is set to 0.5 ~ 1Pa, and the magnetron sputtering ends After that, a SiC wafer with a Ni layer of 230-250 nm deposited on the surface is obtained.

[0047] 2) Metal alloying annealing: place the SiC wafer with a Ni layer deposited on the surface in a high-temperature rapid annealing furnace; pass in argon gas, and when the oxygen content monitoring system shows that the oxygen content inside the equipment cavity is less than 20-30ppm, start Heating, raise the temperature to 970-990°C at a heating rate of 25°C / s, and maintain at this temperature for 3 minutes; naturally cool down, when the temperature drops to 200-300°C, pass CO into the annealing furnace 2 gas to fully expose the SiC wafer to CO 2 In the atmosphere, m...

Embodiment 3

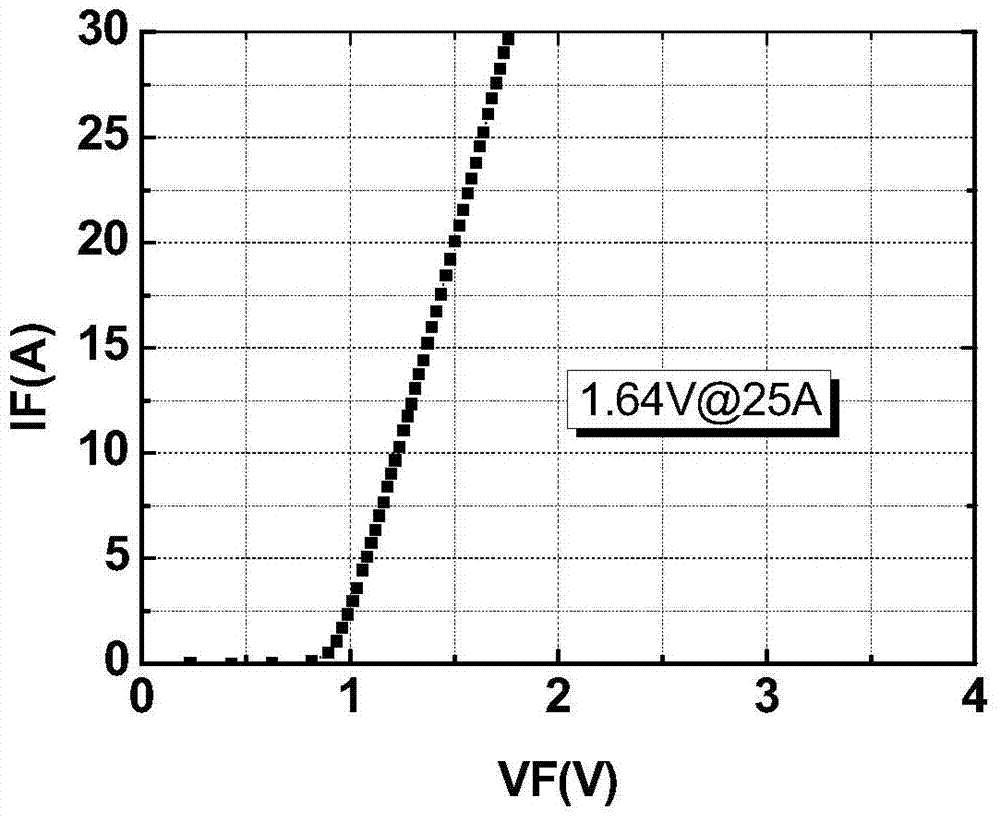

[0049] Fabrication of SiC wafers forming ohmic contacts

[0050] 1) Ohmic contact metal deposition: use magnetron sputtering method to deposit ohmic contact metal on the surface of SiC wafer (4 inches × 400μm), the target material is Ni, the sputtering pressure is set to 0.5 ~ 1Pa, and the magnetron sputtering ends After that, a SiC wafer with a Ni layer of 280-300 nm deposited on the surface is obtained.

[0051] 2) Metal alloying annealing: place the SiC wafer with a Ni layer deposited on the surface in a high-temperature rapid annealing furnace; pass in argon gas, and when the oxygen content monitoring system shows that the oxygen content inside the equipment cavity is less than 20-30ppm, start Heating, raise the temperature to 1025-1050°C at a heating rate of 30°C / s, and maintain at this temperature for 2 minutes; naturally cool down, when the temperature drops to 200-300°C, pass CO into the annealing furnace 2 gas to fully expose the SiC wafer to CO 2 In the atmosphere,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com