Pig raising method based on fermenting bed

A technology of fermentation bed and pig house, applied in the field of livestock breeding, can solve the problems of high breeding cost, poisoning of live pigs, inconvenient management, etc., and achieve the effect of reducing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The specific implementation method of this embodiment includes the following steps:

[0033] (1) Construction of the pig house: The pig house is set up in a rectangular shape with an aspect ratio of 3:1. The ground is made of concrete and is set in an arc shape. There is a fence around the pig house, the fence is 1.0-1.2m high, and a shed is set outside the pig house, and a plastic film roller shutter is placed on the top of the shed;

[0034] (2) Lay the fermentation bed: build the fermentation bed on the ground of the built pig house, pave the upper part of the fermentation bed flat, and the height of the fermentation bed is 30-50cm;

[0035] (3) Feeding piglets: Feed fattening pigs in the fermentation bed pig house, and alternately use the troughs and drinking fountains on both sides of the pig house to supply water and food to piglets.

[0036] Wherein, the drinking fountains arranged on both sides of the pig house are duckbill automatic drinking fountains, the len...

Embodiment 2

[0038] This embodiment further defines the specific construction steps of the fermentation bed on the basis of the above-mentioned embodiments:

[0039] (2.1) Filler: Lay sawdust and 65% rice husks with a weight ratio of 35% to 65% on the ground of the pig house, and lay flat, and the height of the filler at the fence is 40cm;

[0040] (2.2) Fermentation material addition: mix 3% fermented bacteria powder, 48% chaff, 6% activated carbon powder, and 43% peanut shell powder evenly by weight, add them to the filler on the ground of the pig house, stir and mix Uniformly; then sprinkle the aqueous solution containing 1-3% water agent fermentation bacteria evenly on the filler on the ground of the pig house through a watering can, and stir up and down to make it evenly mixed;

[0041] (2.3) Fermentation: continue to sprinkle water on the stuffing in the piggery until the water content in the stuffing reaches 40%, spread the stuffing flat, cover with fine canvas, and ferment for 10 t...

Embodiment 3

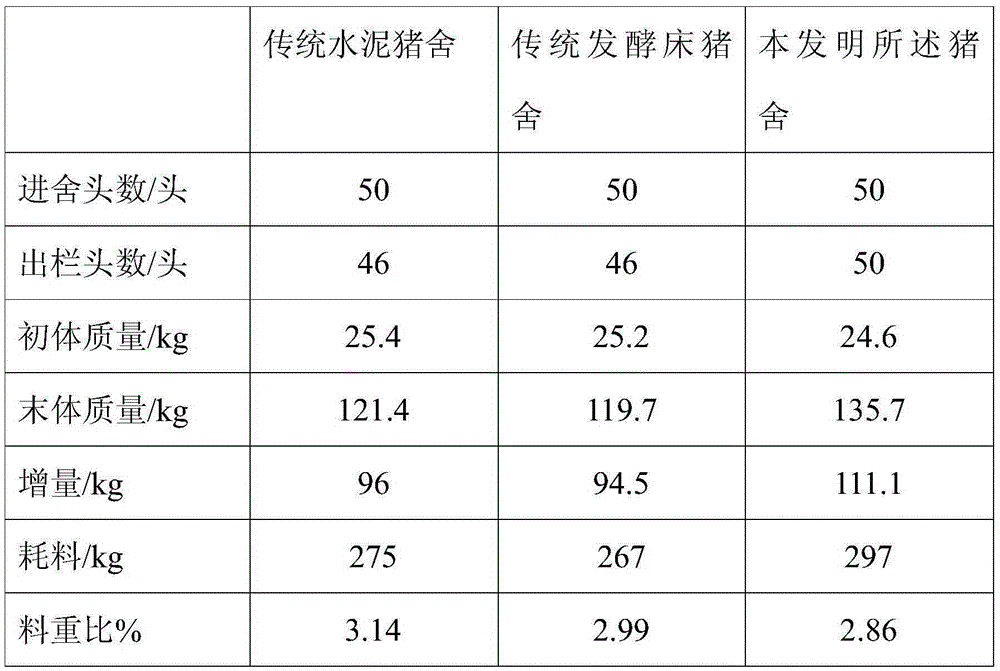

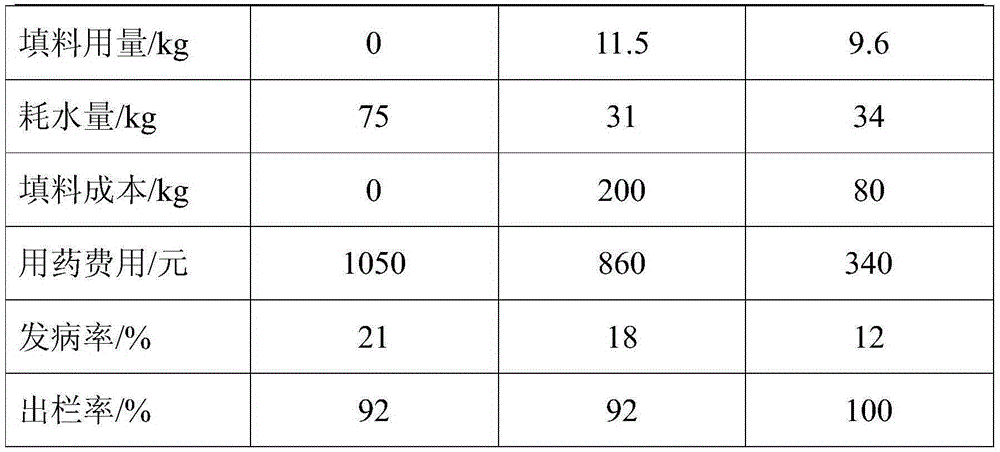

[0044] The present embodiment carries out comparative test for traditional cement pig raising, traditional fermentation bed pig raising and the method of this embodiment pig raising:

[0045] Design three kinds of pig houses, i.e. traditional cement ground pig house, traditional fermentation bed pig house and pig house of the present invention, three kinds of pig houses are all built according to the standard of 1.5m2 / head, and build automatic feeding trough and automatic drinking fountain. The pig houses are kept ventilated and well lit, and roller blinds are installed to adjust the wind and temperature. The traditional fermentation bed pig house digs 60-80 cm down on the ground of the pig living area and spreads bedding; the traditional cement floor pig house has a cement floor; the third type of pig house is built on the bank of the pig house according to the invention.

[0046]

[0047]

[0048] Compared with traditional pig raising on cement floor, the pig raising ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com