Dust-removing modifying agent capable of efficiently capturing, adsorbing and removing smoke dust

A modifier and fume technology, which can be used in the use of liquid separation agents, other chemical processes, dispersed particle separation, etc., can solve the problems of poor dust removal effect, difficult to meet national emission standards, etc., to improve the critical micelle concentration, The effect of improving the capture and adsorption capacity and enhancing the wet strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

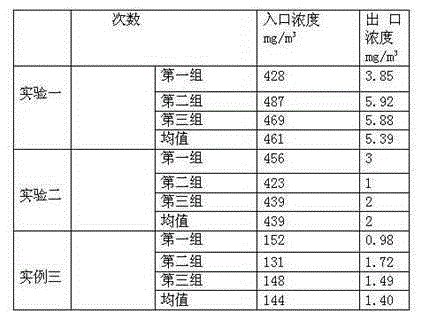

Embodiment 1

[0009] Example 1: A dust removal modifier that efficiently captures, absorbs, and removes soot. The dust removal modifier of this embodiment is suitable for the limestone gypsum method spray dust removal and desulfurization process. Specifically, the modifier of this embodiment is added to the diluted In the limestone solution, the amount added therein is to add 25g of the modifier of this embodiment for every ten tons of water according to the weight ratio. Polyoxyethylene ether 8g, lauryl dimethyl amine oxide 2.5g, alkyl polyglucoside 4g, anhydrous aluminum potassium sulfate 3g, fatty alcohol polyoxyethylene ether 2.5g.

Embodiment 2

[0010] Example 2: A dust removal modifier that efficiently captures, absorbs, and removes soot. The dust removal modifier of this embodiment is suitable for the process of double-alkali desulfurization and dust removal. Specifically, the modifier of this embodiment is added to the circulating water pool for dust removal and desulfurization Within the period, regular maintenance can be carried out according to the circulation cycle of the enterprise's circulating water. The amount to be added is 30 g of the modifier of this embodiment for every ten tons of water according to the weight ratio. 9g, 2.4g of dodecyl dimethyl amine oxide, 3g of alkyl polyglucoside, 4.5g of anhydrous aluminum potassium sulfate, 3.6g of fatty alcohol polyoxyethylene ether.

Embodiment 3

[0011] Example 3: A dust removal modifier that efficiently captures, absorbs and removes smoke and dust. The dust removal modifier of this embodiment is directly used for dust removal spraying. Specifically, the modifier of this embodiment is directly added to water for spraying, wherein the added The amount according to the weight ratio is to add 28g of the modifier of this embodiment for every ten tons of water, and the specific proportion of each component in the modifier is as follows: 4.2g of sodium secondary alkyl sulfonate, 9.8g of hydroxy synthetic alcohol polyoxyethylene ether , 4.2g of dodecyl dimethyl amine oxide, 5.6g of alkyl polyglucoside, 2.8g of anhydrous aluminum potassium sulfate, 1.4g of fatty alcohol polyoxyethylene ether.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com