Method for preparing high-dispersion nitrogen-doped graphene

A nitrogen-doped graphene, highly dispersed technology, applied in the field of preparation of highly dispersed nitrogen-doped graphene, can solve the problems of graphene surface doping, nitrogen loss, and low nitrogen content in the product, so as to achieve less nitrogen loss and easy High-volume production and high-yield effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

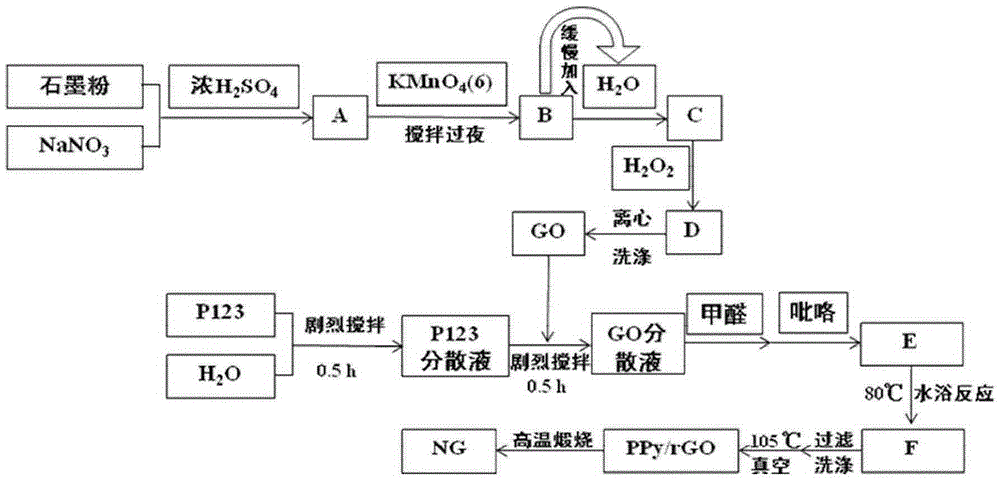

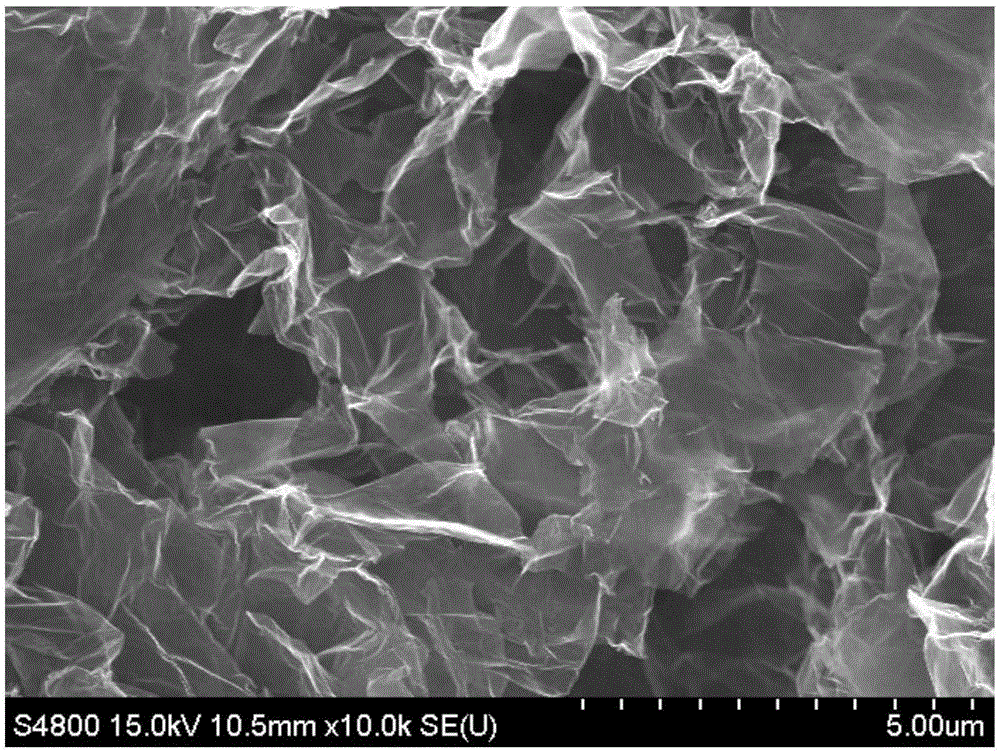

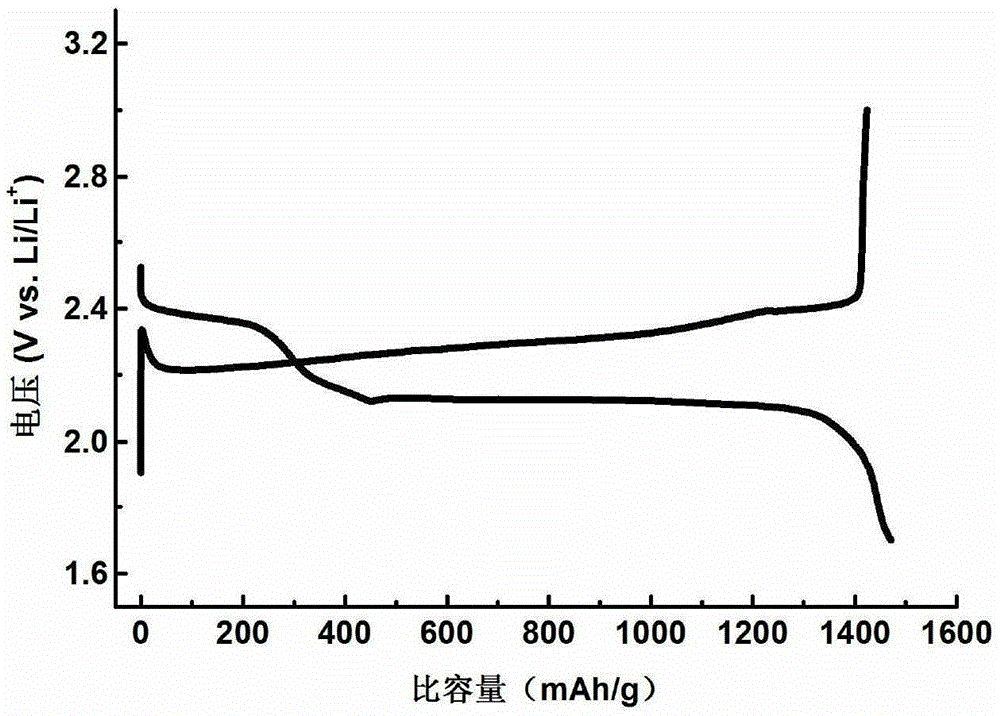

[0027] Weigh 1.0g expanded graphite, 1.0gNaNO 3 , 3.0 g KMnO 4 In a 100mL beaker, slowly add 60mL of concentrated sulfuric acid and stir for 12h. Remove the unreacted expanded graphite floating on the upper layer of the solution, pour the mixed solution into 400mL of water three times and stir, after the beaker is cooled, add hydrogen peroxide (30%, mass fraction) drop by drop until bright yellow graphene oxide (GO) solution is obtained ; centrifuged and washed 3 times with three times of water to obtain brown-yellow GO sol. Disperse 1.0g of P123 into 300mL of water, stir vigorously to produce a large amount of white foam, so that P123 can be fully dispersed. Then GO was added to the P123 dispersion, and the stirring was continued for 30 min to obtain a GO dispersion. 0.4g formaldehyde solution was added to the above GO dispersion; 0.5g pyrrole (Py) was dispersed in 30mL ethanol and 30mL water mixture, ultrasonically dispersed and added to the GO dispersion. The GO dispers...

Embodiment 2

[0031] Weigh 1.0g expanded graphite, 1.0gNaNO 3 , 3.0 g KMnO 4 In a 100mL beaker, slowly add 60mL of concentrated sulfuric acid and stir for 12h. Remove the unreacted expanded graphite floating on the upper layer of the solution, pour the mixed solution into 400mL of water three times and stir, after the beaker is cooled, add hydrogen peroxide (30%, mass fraction) drop by drop until bright yellow graphene oxide (GO) solution is obtained ; Centrifuged and washed 3 times with three times of water to obtain brown-yellow G0 sol. Disperse 1.0 g of P123 into 300 mL of water, stir vigorously to generate a large amount of white foam, so that P123 is fully dispersed, then add GO to the P123 dispersion, and continue stirring for 30 min to obtain a GO dispersion. 0.4g formaldehyde solution was added to the above GO dispersion; 0.5g pyrrole (Py) was dispersed in 30mL ethanol and 30mL water mixture, ultrasonically dispersed and added to the GO dispersion. The GO dispersion was transferr...

Embodiment 3

[0033] Weigh 1.0g expanded graphite, 1.0gNaNO 3 , 3.0 g KMnO 4In a 100mL beaker, slowly add 60mL of concentrated sulfuric acid and stir for 12h. Remove the unreacted expanded graphite floating on the upper layer of the solution, pour the mixed solution into 400mL of water three times and stir, after the beaker is cooled, add hydrogen peroxide (30%, mass fraction) drop by drop until bright yellow graphene oxide (GO) solution is obtained ; centrifuged and washed 3 times with three times of water to obtain brown-yellow GO sol. Disperse 1.0 g of P123 into 300 mL of water, stir vigorously to generate a large amount of white foam, so that P123 is fully dispersed, then add GO to the P123 dispersion, and continue stirring for 30 min to obtain a GO dispersion. 0.4g formaldehyde solution was added to the above GO dispersion; 0.4g pyrrole (Py) was dispersed in 30mL ethanol and 30mL water mixture, ultrasonically dispersed and added to the GO dispersion. The GO dispersion was transferre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com