Method for synthesizing monodisperse SiO<2> micrometer-size particles through one-step method

A micro-particle, monodisperse technology, applied in the direction of silicon oxide, can solve the problems of easy gelation of particles, time-consuming, troublesome operation, etc., and achieve the effect of good monodispersity and simple and effective synthesis method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

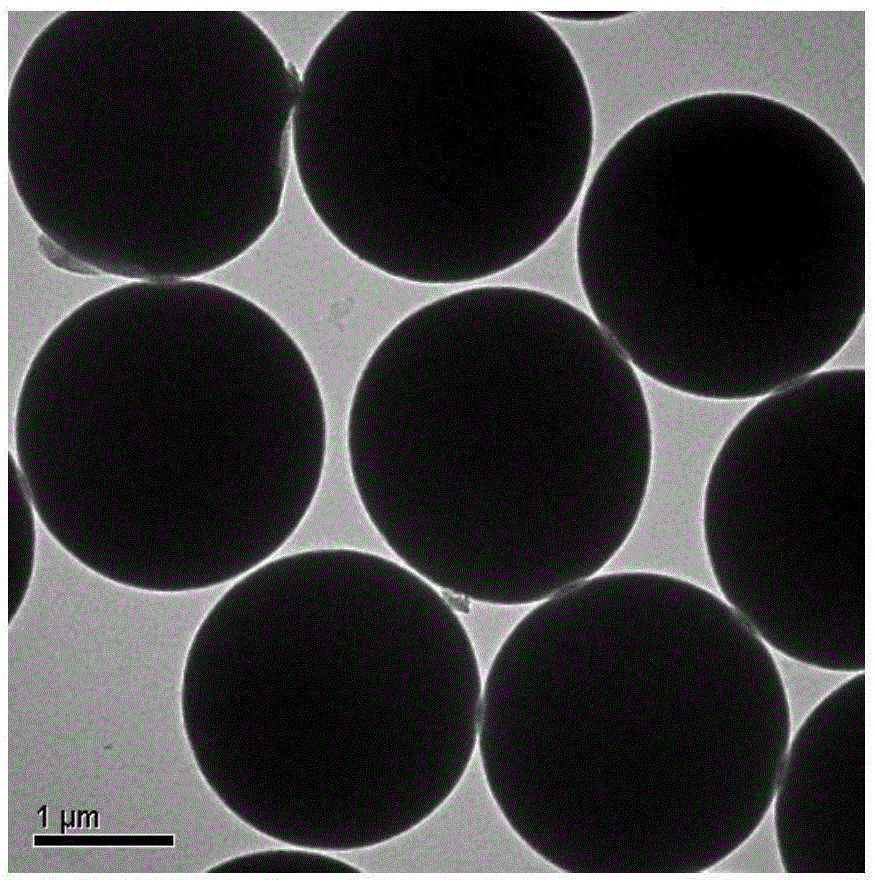

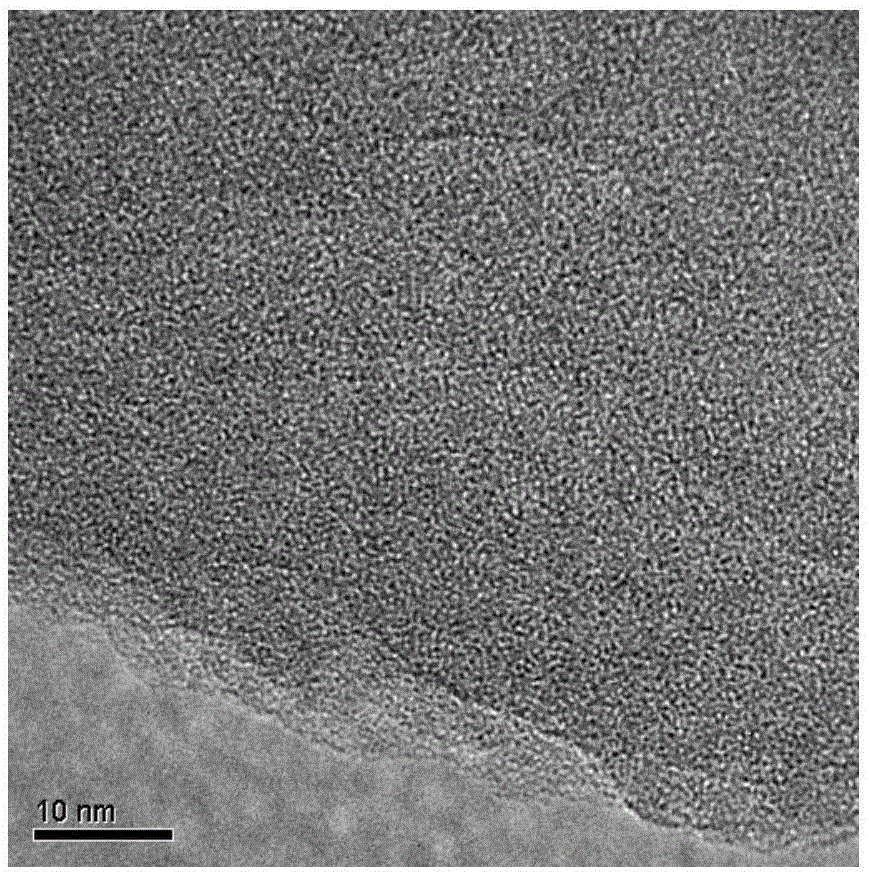

[0023] In 25mL ethanol system, add 15mL water, then add 0.5mL analytical pure ammonia solution (mass fraction 25-28%), 0.08g CTAB (analytical pure), when the reaction temperature is constant to 25°C, after CTAB is completely dissolved, add 0.5mL Tetraethyl orthosilicate, continue to stir at a constant temperature of 25°C for 3 hours, centrifuge to remove the supernatant after the reaction, wash twice, dry the particles at 120°C, and then calcinate at 550°C for 5 hours to remove impurities such as CTAB , to obtain 2 μm well monodispersed SiO 2 Micron particles, the TEM images of which are shown in figure 1 As shown, the HTEM map is shown as figure 2 shown, from figure 2 It can be seen that there is no ordered mesoporous structure in the microstructure of the particles, but a microporous structure.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com