A kind of strongly basic anion exchange resin and preparation method thereof

An exchange resin and anion technology, applied in anion exchange, ion exchange, chemical instruments and methods, etc., can solve the problems of strong carcinogenicity, low boiling point, volatile, health threat to production operators, and impact on the sustainable development of the industry. Development prospects and practical significance, the effect of solving safety and environmental protection problems, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

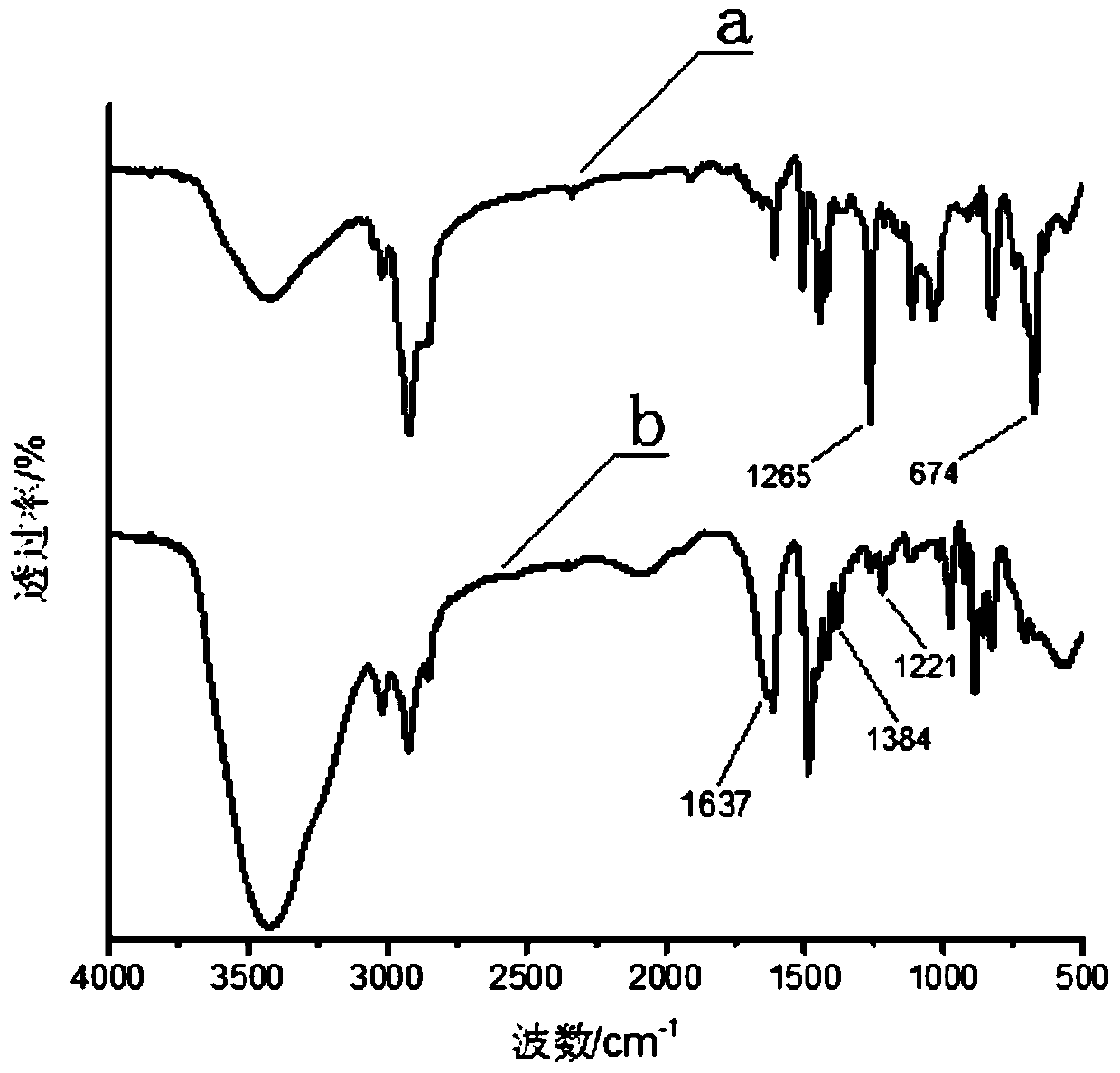

[0052] (1) Chloromethylation of cross-linked polystyrene

[0053] Add 53 parts of n-heptanol, 6 parts of paraformaldehyde, and 55 parts of dichloromethane into the reaction container in sequence, and drop 51 parts of thionyl chloride into the container. The dropping time is controlled at 3 hours, and the temperature is controlled at 3-5°C. After the dropwise addition, react at 3-10°C for 4h. After the reaction, add 10 parts of cross-linked polystyrene resin (cross-linking degree is 7%) swollen with 32 parts of dichloromethane in the system in advance, add dropwise 28 parts of tin tetrachloride under stirring, control at 3- 5°C, the dropwise addition was completed in 2h, and the reaction was continued for 20h, and the temperature was controlled at 15-22°C. After the reaction, the reaction solution was filtered, and the resulting filter balls were washed with hydrochloric acid aqueous solution, dioxane, and deionized water with a mass fraction of 10-33%, and dried in vacuum at ...

Embodiment 2

[0061] (1) Chloromethylation of cross-linked polystyrene

[0062] Add 24 parts of n-heptanol, 8 parts of paraformaldehyde, and 27 parts of dichloromethane into the reaction container in sequence, and drop 38 parts of thionyl chloride into the container. The dropping time is controlled at 3 hours, and the temperature is controlled at 3-5°C. After the dropwise addition, react at 3-10°C for 4h. After the reaction, add 9 parts of cross-linked polystyrene resin (cross-linking degree is 7%) swollen with 32 parts of dichloromethane in advance in the system, add dropwise 22 parts of tin tetrachloride under stirring, control at 3- 5°C, the dropwise addition was completed in 2h, and the reaction was continued for 20h, and the temperature was controlled at 15-22°C. After the reaction is finished, the reaction liquid is filtered, and the obtained filter balls are washed with 10-33 wt% hydrochloric acid aqueous solution, dioxane, and deionized water, and vacuum-dried at 60° C. to obtain c...

Embodiment 3

[0069] (1) Chloromethylation of cross-linked polystyrene

[0070] Add 25 parts of n-heptanol, 6 parts of paraformaldehyde, and 23 parts of dichloromethane into the reaction container in sequence, and drop 63 parts of thionyl chloride into the container. The total dropping time is controlled at 3 hours, and the temperature is controlled at 3-5°C , After the dropwise addition, react at 3-5°C for 4h. After the reaction, add 11 parts of cross-linked polystyrene resins swollen with 32 parts of dichloromethane in advance in the system (cross-linking degree is 7%), add dropwise 30 parts of tin tetrachloride under stirring, control at 3- 5°C, the dropwise addition was completed in 2h, and the reaction was continued for 20h, and the temperature was controlled at 10-15°C. After the reaction, the reaction solution was filtered, and the obtained filter balls were washed with 10-33 wt% hydrochloric acid aqueous solution, dioxane, and deionized water, and dried in vacuum at 60°C to obtain ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| cross-linking degree | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com