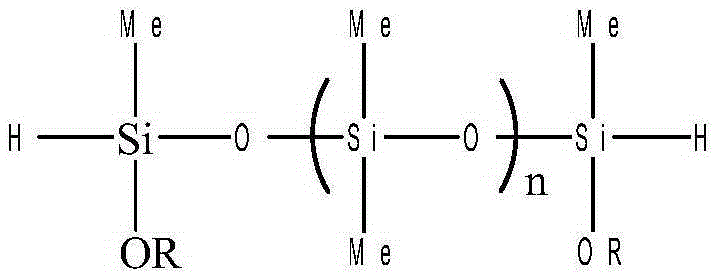

Hydrogen-containing silicone oil and preparation method thereof

A technology containing hydrogen-containing silicon and potassium hydroxide, applied in the field of hydrogen-containing silicone oil and its preparation, can solve the problems of high price and sharp increase in raw material cost, and achieve the effect of low price and good cost advantage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

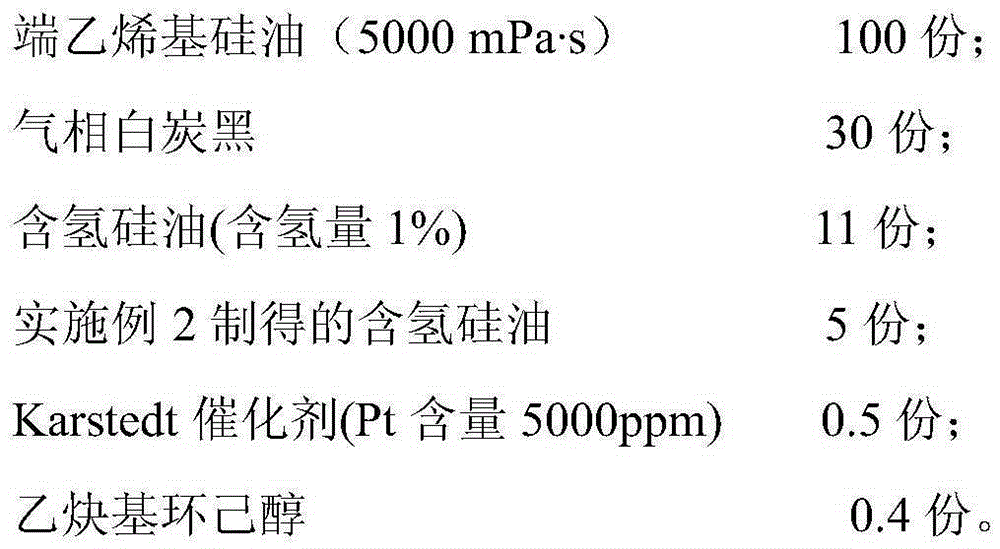

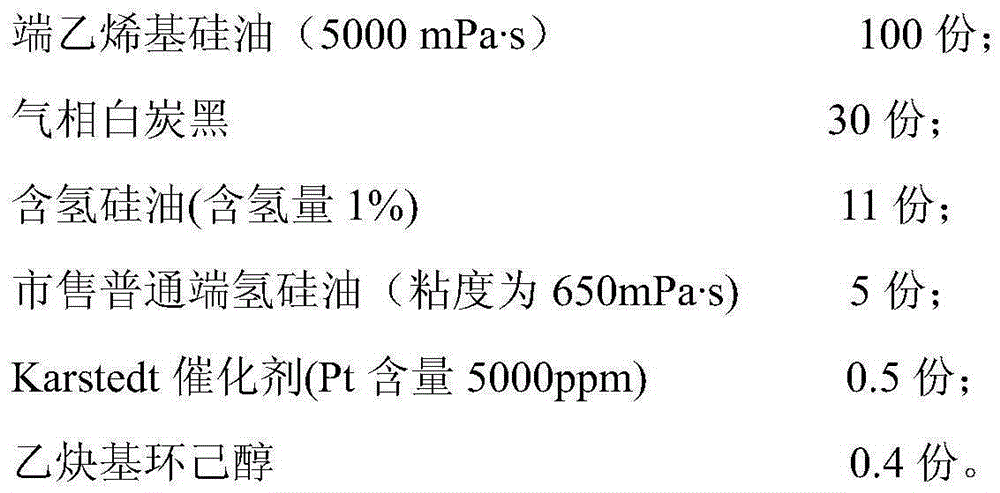

Examples

Embodiment 1

[0031] Add 1000g of linear body into the reaction kettle, stir, heat up to 130°C, add 0.025g of potassium hydroxide, keep the temperature at 130°C, vacuumize, check the viscosity online, when the viscosity reaches 10000mPa·s, return to normal pressure, add phosphoric acid 0.03 g, neutralize for 1 hour, then lower the temperature to 80°C, add 30g of methyldiethoxysilane and 10g of triethylamine, stir the reaction for 1 hour, raise the temperature to 140°C, remove the low molecular weight by vacuuming for 2 hours, and obtain the hydrogen-containing Silicone oil, viscosity 984mPa·s, hydrogen content (mass content) 0.0054%.

Embodiment 2

[0033] Add 1000g of linear body into the reaction kettle, stir, raise the temperature to 135°C, add 0.015g of potassium hydroxide, keep the temperature at 135°C, vacuumize, check the viscosity online, when the viscosity reaches 5000mPa·s, return to normal pressure, add silicon base Phosphate (calculated as phosphoric acid) 0.023g was neutralized for 0.8h, then cooled to 70°C, added 35g of methyldiethoxysilane and 20g of dipropylamine, stirred for 3h, heated to 120°C, vacuumed to remove low molecular weight for 4h , to obtain the hydrogen-containing silicone oil with a viscosity of 4930mPa·s and a hydrogen content (mass content) of 0.0066%.

Embodiment 3

[0035] Add 1000g of linear body into the reaction kettle, stir, raise the temperature to 140°C, add 0.008g of potassium hydroxide, keep the temperature at 140°C, vacuumize, check the viscosity online, when the viscosity reaches 650mPa·s, return to normal pressure, add silicon base Phosphate ester (calculated as phosphoric acid) 0.014g was neutralized for 0.5h, then the temperature was lowered to 60°C, 50g of methyldiethoxysilane and 30g of cyclohexanone oxime were added, stirred for 2h, the temperature was raised to 130°C, vacuum removed Molecule 3h, the hydrogen-containing silicone oil is obtained, the viscosity is 4930mPa·s, and the hydrogen content (mass content) is 0.0135%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com