Ecological textile auxiliary

An ecological additive and nano-titanium dioxide technology, applied in textiles and papermaking, biochemical fiber treatment, fiber treatment, etc., can solve the problems of poor antibacterial performance and poor strength, and achieve the effect of easy dyeing, simple use and delicate hand feeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

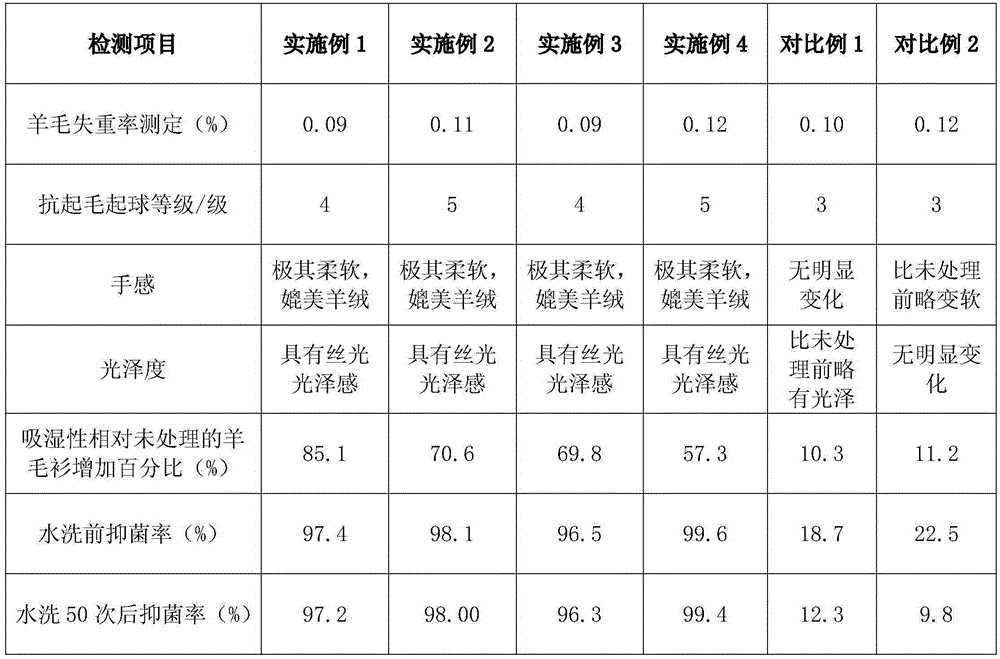

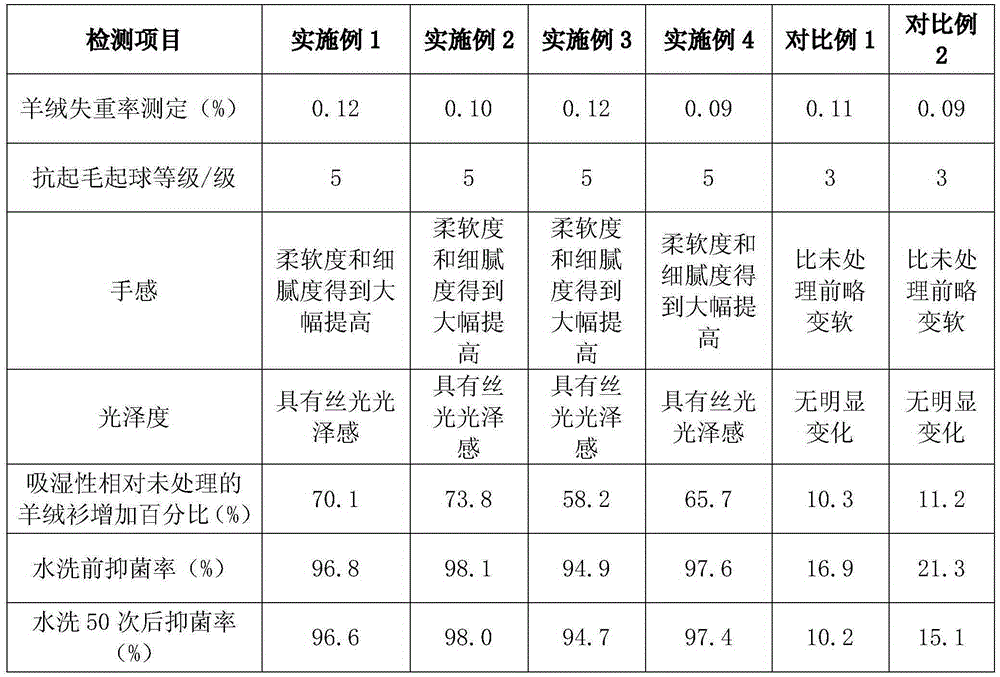

Examples

Embodiment 1

[0017] The application of ecological additives in woolen sweater finishing, the steps are as follows:

[0018] (1) Preparation of ecological additives:

[0019] Agent A: Mix acidophilus, Bacillus subtilis, and Candida according to the strain ratio of 1:0.3:0.5 to make 1*10 5 The bacterial suspension, the bacterial suspension also contains, according to the mass percentage, 0.3% trehalose, 0.2% stachyose, and 0.05% nano-titanium dioxide;

[0020] B agent: according to mass percentage, silk fibroin 1.5%, pigskin collagen 0.6%, water-soluble chitosan 0.2%, 0.08% nano-titanium dioxide;

[0021] (2) Finishing:

[0022] First, spray agent B evenly on the woolen sweater, the spraying weight is 0.1 times of the weight of the woolen sweater, then put it at 28°C for 12 hours, dry it at 30°C, and set it aside;

[0023] Then spray agent A evenly on the dried woolen sweater, the sprayed weight is 0.08 times the weight of the woolen sweater, and then put it at 35°C for 420min, keep const...

Embodiment 2

[0026] The application of ecological additives in woolen sweater finishing, the steps are as follows:

[0027] (1) Preparation of ecological additives:

[0028] Agent A: Prepare 1.5*10 by mixing Micrococcus acidophilus, Bacillus subtilis, and Candida according to the ratio of the number of strains: 1:0.3:0.5 5 The bacterial suspension, the bacterial suspension also contains, according to the mass percentage, 0.3% trehalose, 0.2% stachyose, and 0.05% nano-titanium dioxide;

[0029] B agent: according to mass percentage, silk fibroin 1.0%, pigskin collagen 0.9%, water-soluble chitosan 0.2%, 0.08% nano-titanium dioxide;

[0030] (2) Finishing:

[0031] First, spray agent B evenly on the woolen sweater, the spraying weight is 0.1 times the weight of the woolen sweater, then put it at 25°C for 15 hours, dry it at 30°C, and set it aside;

[0032] Then spray agent A evenly on the dried woolen sweater, the weight of the spray is 0.05 times the weight of the woolen sweater, and then...

Embodiment 3

[0035] The application of ecological additives in woolen sweater finishing, the steps are as follows:

[0036] (1) Preparation of ecological additives:

[0037] Agent A: Prepare 1.1*10 of Pediococcus acidophilus, Bacillus subtilis, and Candida according to the strain ratio of 1:0.3:0.5 5 The bacterial suspension, the bacterial suspension also contains, according to the mass percentage, 0.3% trehalose, 0.2% stachyose, and 0.05% nano-titanium dioxide;

[0038] B agent: according to mass percentage, silk fibroin 1.4%, pigskin collagen 0.7%, water-soluble chitosan 0.2%, 0.08% nano-titanium dioxide;

[0039] (2) Finishing:

[0040] First, spray agent B evenly on the woolen sweater, the spraying weight is 0.1 times the weight of the woolen sweater, and then put it at 27°C for 13 hours, dry it at 30°C, and set it aside;

[0041] Then spray agent A evenly on the dried woolen sweater, the sprayed weight is 0.07 times the weight of the woolen sweater, and then put it at 36°C for 400 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com