A Surface Plasmon Resonance High Refractive Index Sensor Based on Porous Aluminum Film Structure and Its Application

A surface plasmon, high refractive index technology, applied in the field of sensors, can solve the problems of small contrast, low excitation efficiency, poor stability, etc., and achieve the effect of high productivity, low cost, and effective detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

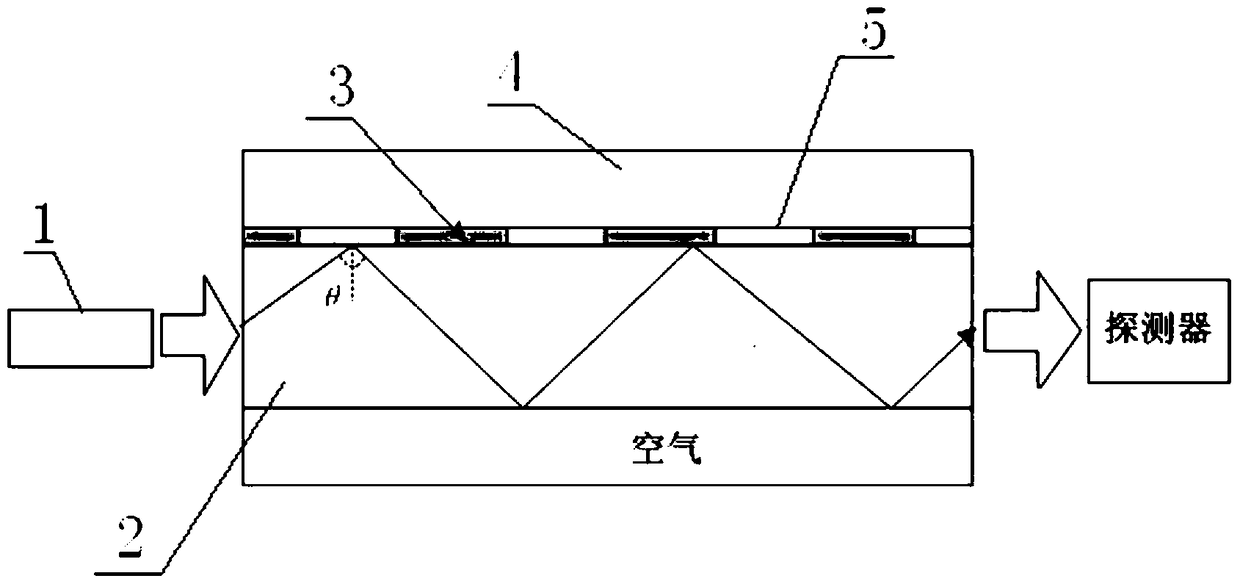

[0036] Such as figure 1 shown.

[0037] A surface plasmon resonance high-refractive index sensor based on a porous aluminum film structure comprises a quartz waveguide, a porous metal aluminum film layer arranged on the upper surface of the quartz waveguide, an incident light source and a detector.

[0038] The thickness of the porous metal aluminum film layer is 10-100nm.

[0039] The thickness of the quartz waveguide is 1-10mm.

[0040] The incident light source is an LED light source with an incident wavelength of 400-750nm.

[0041] Holes with a diameter of 100-200nm are arranged on the porous metal aluminum film layer, and the arrangement period of the holes is 200nm-400nm.

Embodiment 2

[0043] The preparation method of porous metal aluminum film layer as described in embodiment 1 comprises:

[0044] First, spin-coat photoresist on the upper surface of the quartz waveguide;

[0045] Secondly, the two-dimensional periodic hole pattern is directly written on the photoresist by electron beam lithography;

[0046] Then, use a coating machine to coat a layer of metal aluminum film;

[0047] Finally, the photoresist and the circular metal aluminum film layer attached to the photoresist are removed to obtain a porous metal aluminum film layer.

Embodiment 3

[0049] A sensing method utilizing a sensor as described in embodiment 1, comprising steps as follows:

[0050] 1) The incident light source is coupled into the quartz waveguide, and due to the total reflection effect, the incident light is transmitted under the constraint of the quartz waveguide;

[0051] 2) After the incident light reaches the porous metal aluminum film layer, the incident light is coupled out through the quartz waveguide, and forms a plasmon resonance effect on the surface of the porous metal aluminum film layer;

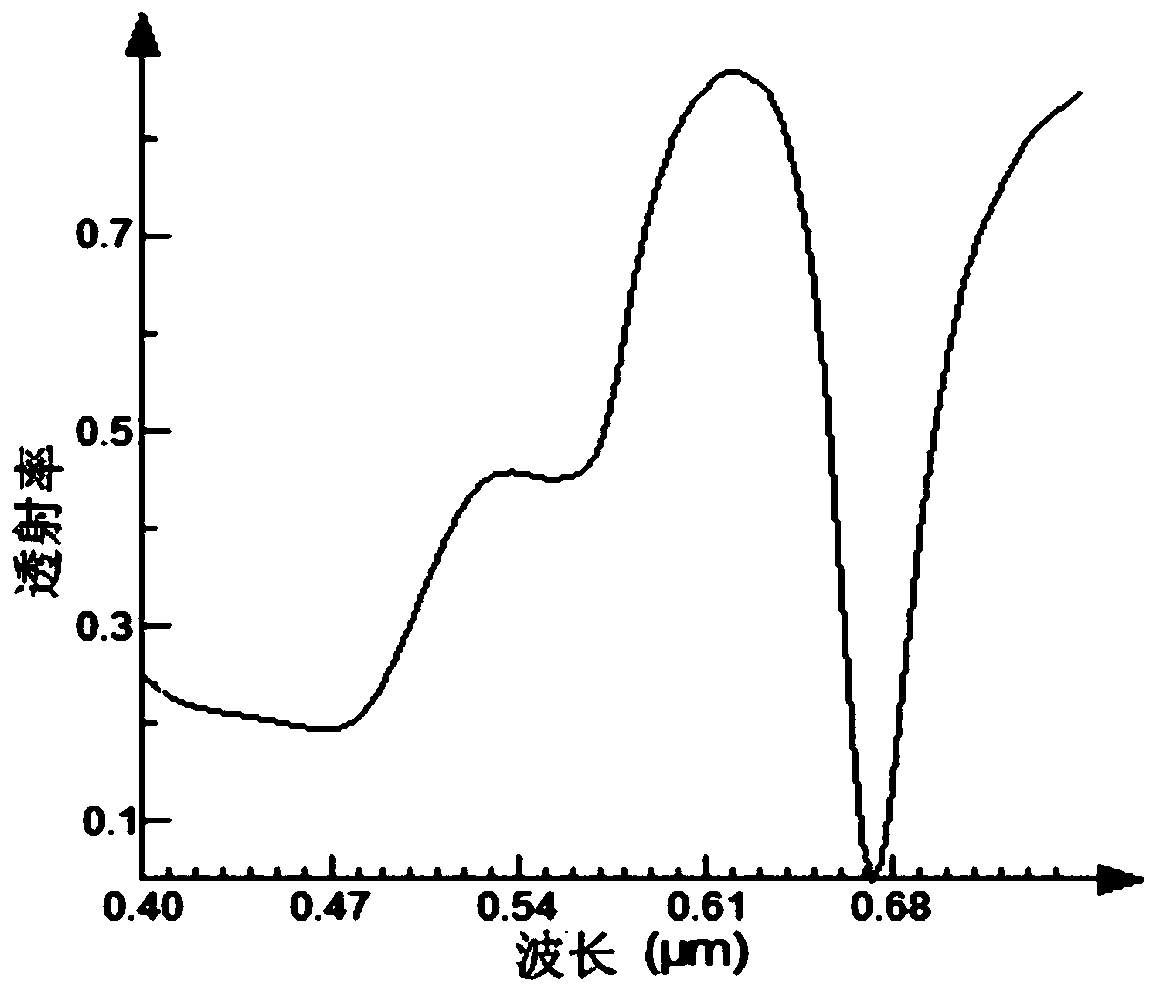

[0052] 3) Due to the limitation of matching conditions: under different wavelengths of incident light, the coupling efficiency of light is different; the coupling efficiency reaches the maximum at a specific wavelength of light, forming a spectral resonance absorption peak; The increase of the ambient refractive index moves to the long-wave direction, so as to realize the measurement of the refractive index of the environment where the sensor is l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com