Evaluation method for dimension expansion and contraction of glass fiber fabric base layer pressing plate

An evaluation method and technology of glass fiber cloth, which can be used in measuring devices, instruments, scientific instruments, etc., which can solve the problem that the shape and area of glass fiber cloth weaving nodes cannot be solved, and the dimensional stability or expansion and shrinkage changes of glass fiber cloth-based laminates cannot be applied. It can avoid the high sampling cost, the detection method is simple and easy to implement, and the test cost can be reduced.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

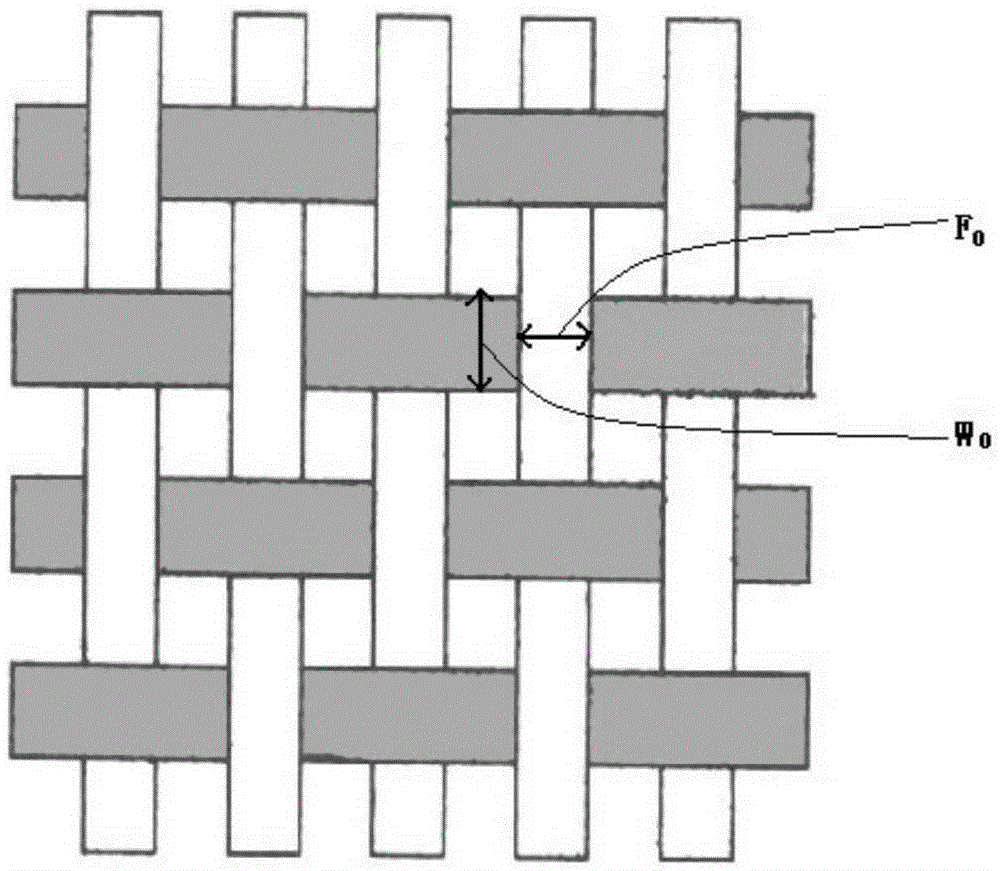

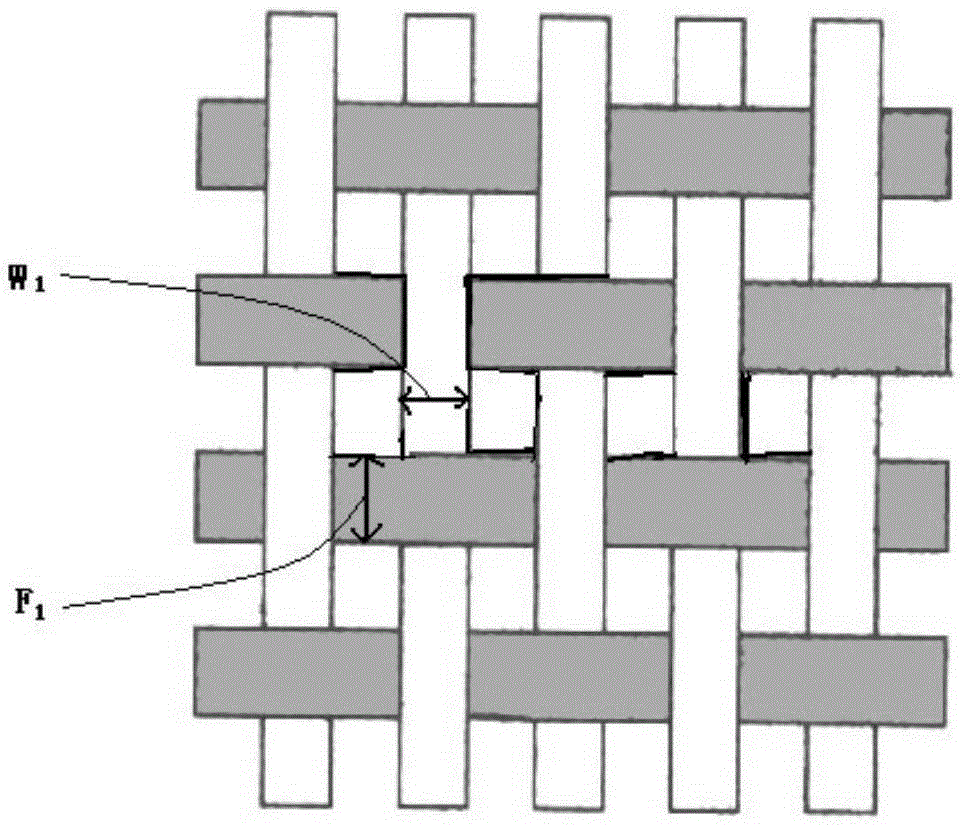

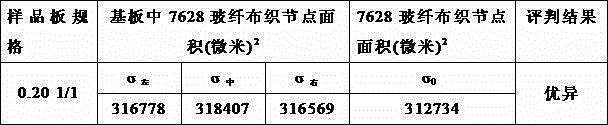

[0045] See attached Figure 1~2 As shown, a method for evaluating the size expansion and contraction of glass fiber cloth-based laminates,

[0046] The manufacturing process of the glass fiber cloth-based copper-clad laminate comprises the following steps: taking Taiwan Huber, model 7628 (basis weight 210g / m 2 ) glass fiber cloth is unrolled and then moved into the glue tank, impregnated with a resin mixture mainly composed of epoxy resin and other thermosetting resins, the resin content is precisely controlled by metering rollers, heated and dried in an oven, and a prepreg is obtained; After the 7628 prepregs are combined according to the process specifications, they are covered with 1OZ copper foil up and down, and the mirror steel plates are used to separate the laminates, and sent to the vacuum lamination machine, and the sheet laminates are made under a certain temperature, pressure and vacuum degree. The thickness of the substrate is 0.20mm, and both sides are covered w...

Embodiment 2

[0056] This example is basically similar to Example 1, the difference is that Shanghai Honghe, model 106 glass fiber cloth is unrolled to make 106 prepreg, and a single sheet 106 is used to press the substrate with a thickness of 0.05mm, and both sides are covered with 1 / 3OZ (abbreviated TOZ, the same below) copper foil.

[0057] The performance of the dimensional stability of the 0.05T / T substrate was evaluated by the same method as in Example 1. The relevant test data and evaluation standards are shown in Table 2 below.

[0058] Table 20. Summary of Dimensional Stability Evaluation Data for 05T / T Thin Fiberglass Cloth-Based Laminates

[0059]

[0060] It can be seen from Table 2 that the difference between the standard deviation of the node area of the 106 fiberglass cloth at the left, middle and right positions of the 0.05T / T base material and the standard deviation of the original area of the 106 fiberglass cloth of this specification is 3.09% and 2.15% respectively...

Embodiment 3

[0062] On the basis of Example 1, the test sample was baked at the glass transition temperature Tg+5°C of the material, that is, the baking temperature was 155°C, and the baking time was 2 hours. details as follows:

[0063] Take the sample of the thin glass fiber cloth-based laminate to be tested, chemically etch away the copper foil coated on both sides, then wash, dry, and perform baking treatment, punching at different positions along the warp or weft edge of the substrate Take the test sample block;

[0064] Under the CCD lens, read the yarn width and yarn distance data of the glass fiber cloth in the warp and weft directions of 10 groups of substrates, and then calculate the area of the glass fiber cloth weaving nodes; the randomly read continuous ten tissue node area data Minitab analysis software, Find the standard deviation of the area of the fiberglass cloth weaving nodes in this piece of test sample;

[0065] Further, compare the standard deviation of the area...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com