Laser head, laser including the laser head and use method

A laser head and laser technology, applied in the field of lasers, can solve the problems affecting the service life of the laser head, high heat, restricting the development prospect of laser cladding technology, etc., and achieve the effects of improving operability, high safety factor, and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

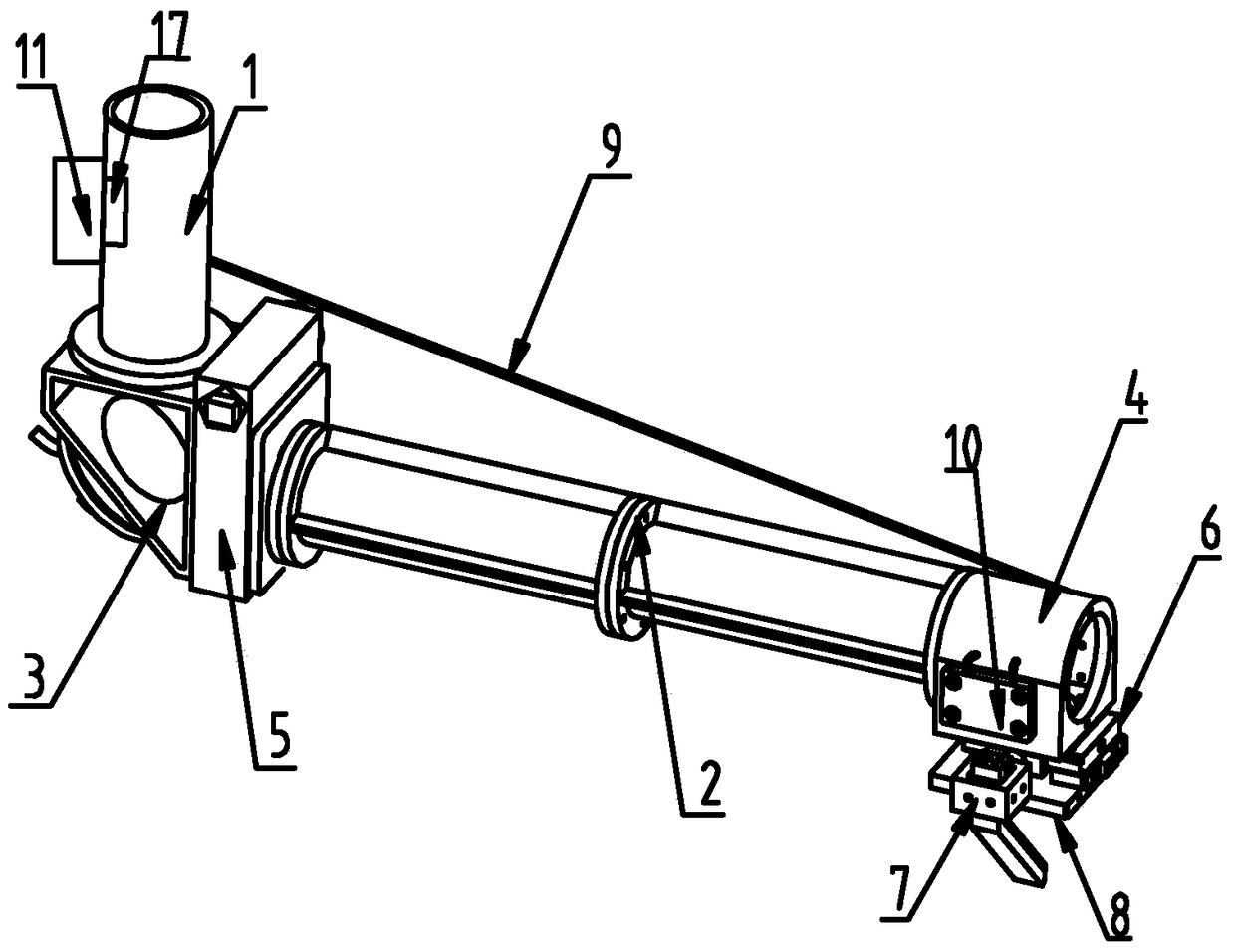

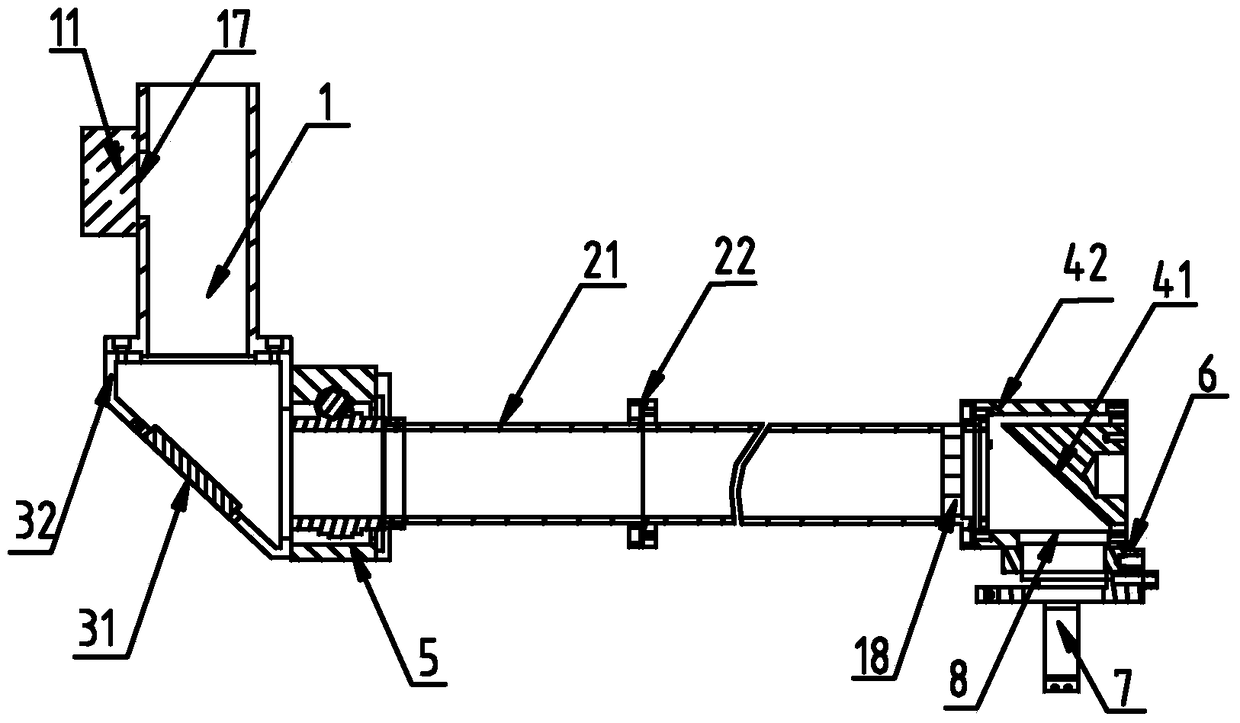

[0042] Such as figure 1 As shown, a laser head includes a transition tube 1, a light guide part 2 and a light outlet 8. One end of the light guide part 2 is provided with a transition tube 1, and the other end is provided with a light outlet 8. The light outlet 8 A powder feeding device 7 and a shielding gas device 6 are provided at the place, the powder feeding device 7 includes a powder feeding head and a fixed part, a cooling part 10 is arranged inside the powder feeding head, and the powder feeding head can slide along the fixing part , it is convenient to adjust the powder feeding angle. The protective gas device 6 includes an air curtain part and a light shielding part in turn from top to bottom. A cooling part 10 is arranged inside the light shielding part, and the light shielding part can effectively prevent the cladding process The slag generated in the process is splashed into the laser head to avoid damage to various components.

[0043] The transition cylinder 1 a...

Embodiment 2

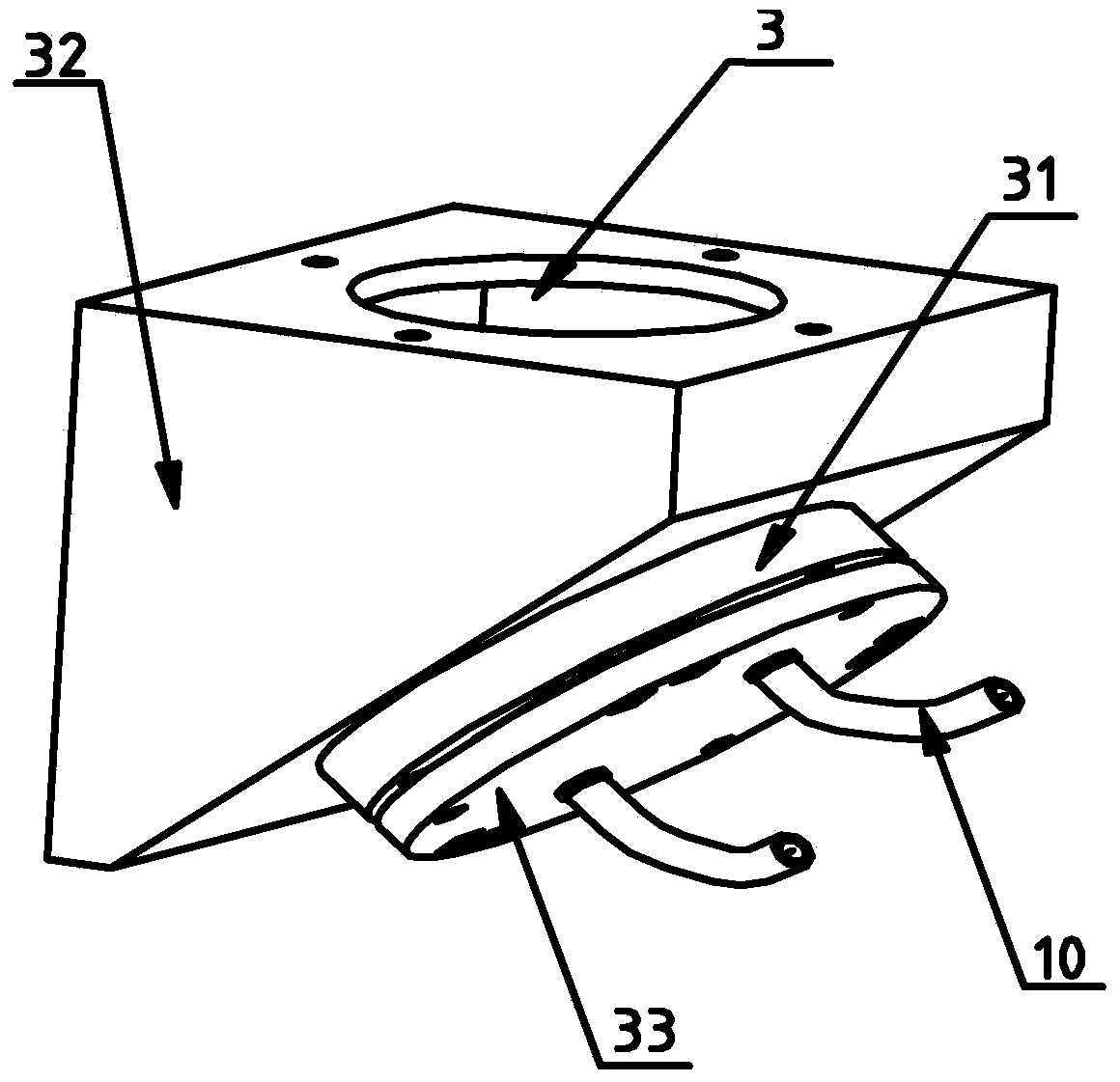

[0049] Such as figure 2 , image 3 As shown, the reflector group 3 includes a mirror base 32 and a reflector 31, the reflector 31 is arranged in the mirror base 32, and the angle between the reflector 31 and the horizontal plane is 44-46°, the reflector A reflector cover 33 is provided on the back of the mirror 31, and a molybdenum film is provided on the reflective surface of the reflector 31 to effectively prevent the laser from dissipating heat.

[0050] Such as Figure 3-6 As shown, the inside of the mirror base 32 and the reflector 31 are provided with an adjustment hole 15, the inside of the reflector cover 33 and the reflector 31 are provided with an adjustment hole 16, and the inside of the adjustment hole 15 is provided with an internal thread , the reflector group 3 also includes an adjustment member, the surface of the adjustment member is provided with an external thread matching the internal thread, the adjustment member includes an adjustment member 12, an adj...

Embodiment 3

[0059] Such as figure 1 , Figure 7 , Figure 8 As shown, an adjustment device 5 is provided at the joint between the light guide part 2 and the reflector group 3, and the adjustment device 5 includes a matching scroll 51 and a turbine 52, and the turbine 52 is connected with the light guide part 2, A worm rod 51 is arranged above the turbine 52, and the turbine 52 is driven to rotate by twisting the worm rod 51, and then drives the light guide part 2 and the integrator mirror group 4 to realize a 360° rotation, and adjusts the exit angle of the laser light. Improve the operability of cladding inside hollow components, with high flexibility and strong practicability.

[0060] Such as figure 2 As shown, the junction of the integrator mirror group 4 and the light guide part 2 is provided with a heat insulation part 18, which effectively prevents the heat generated during the laser cladding process from being transferred to the light guide part 2 and the reflector group 3, fu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com