Power distribution cabinet with functions of heat dissipation and dust removal

A power distribution cabinet and function technology, which is applied in the substation/distribution device shell, electrical components, substation/switch layout details, etc. Equipment short circuit and other problems, to achieve good heat dissipation and dust removal, improve dust removal effect, and reduce energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

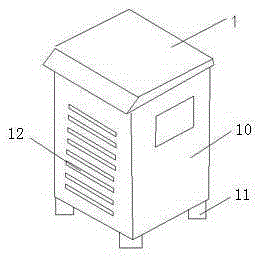

[0023] The power distribution cabinet with the function of heat dissipation and dust removal includes a cabinet body 1 and a cabinet door 10 connected to each other. The bottom of the cabinet body 1 is provided with a foot 11 , and the cabinet body 1 is provided with a heat dissipation port 12 . The cooling outlet 12 is 15 strip-shaped cooling holes juxtaposed, and the size of the cooling outlet 12 is 20cm*0.5cm.

Embodiment 2

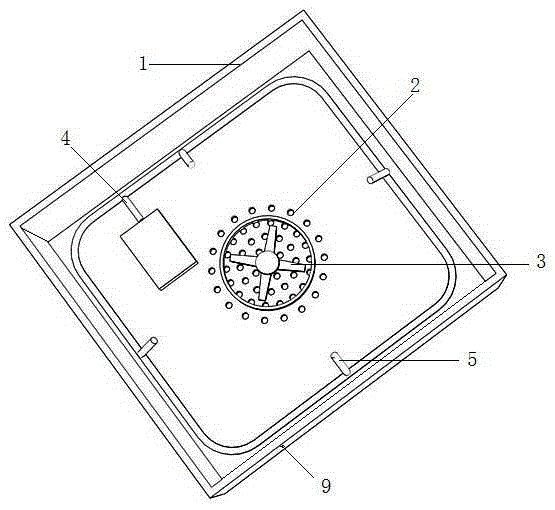

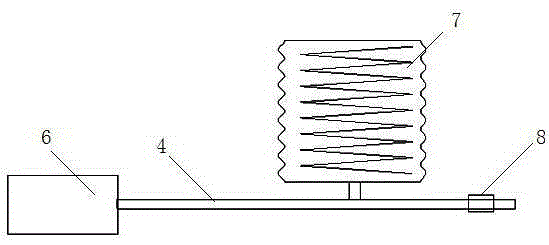

[0025] On the basis of Embodiment 1, the power distribution cabinet with heat dissipation and dust removal function also includes: the heat dissipation port 12 is a plurality of uniformly distributed heat dissipation holes 2, and an exhaust fan 3 is installed in the cabinet corresponding to the heat dissipation port; The air fan 3 is evenly fixed with four spray pipes 5 communicated with the air guide tube 4; the air guide tube 4 is connected with an air pump 6; The electromagnetic switch valve 8 is installed at the end; the electromagnetic switch valve 8, the air pump 6 and the exhaust fan 3 are electrically connected in series, and are connected to the power supply circuit of the power distribution cabinet through the dust removal switch 9; the air injection pipe 5 is a serpentine positioning hose; The dust removal switch 9 is installed on the outer surface of the cabinet 1 .

[0026] The utility model adopts the combination of air injection and exhaust, uses the air injecti...

Embodiment 3

[0029] The surface of the cabinet body 1 in embodiment 1 or 2 is provided with a heat-dissipating paint.

[0030] A method for preparing a heat-dissipating paint, comprising the following steps: mixing 40 parts of polyvinyl butyral, 60 parts of aluminum tripolyphosphate, 55 parts of ethyl acetate, 50 parts of phenyltriethoxysilane, and triglycidyl isocyanurate 60 parts of ester, 80 parts of propylene glycol sebacate polyester, 45 parts of isoprene, 30 parts of tert-butyl hydroperoxide, 60 parts of m-aminomethylamine, 70 parts of dibutyltin dilaurate, 60 parts of N-methylpyrrolidone 50 parts of pentachlorobiphenyl, 55 parts of acetyl tri-n-hexyl citrate, mix well, heat to 40-50°C, add 50 parts of hexadecyltrimethylammonium bromide, 25 parts of epoxidized soybean oil, 50 parts of simethicone oil, stir evenly.

[0031] The stirring speed is 400 revolutions per minute, and the stirring time is 15 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com