Treatment gun

A treatment gun and gun casing technology, applied in the field of treatment guns, can solve the problems of no risk control measures, performance impact of treatment guns, impact on treatment effects, etc., achieve optimal treatment temperature, achieve treatment time, and good treatment effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

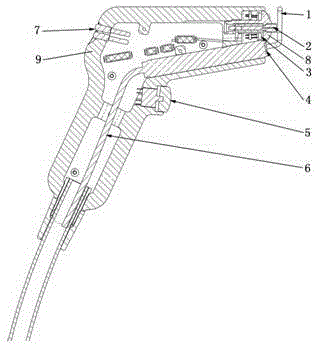

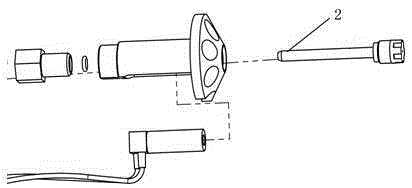

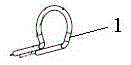

[0049] figure 1 It is a schematic diagram of the overall structure of the present invention. figure 1 Among them, in addition to the gun head 8, the gun shell 9, the switch 5, the gas pipe 6, and the LED warning light 7, the therapeutic gun is additionally equipped with a protective frame 1, a flow valve 2, a three-color LED light 3, a temperature sensor 4, and the like.

[0050] Gun head 8 is arranged on gun shell 9 front ends among the present invention, and air pipe 6 is installed in gun shell 2 afterbody, switch 5 is located at gun shell 9 waist side, and LED warning light 7 is located at gun shell 9 waist back side. Switch 5 is used to control the startup and shutdown of the treatment gun, after a long press, the CO 2 Can be sprayed continuously. CO 2 It is sprayed out from the gas cylinder and reaches the treatment gun after passing through the air pipe 6. The LED warning light 7 indicates whether the preset time is reached and whether it is below +4°C.

[0051] Suc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com