Morinda officinalis oligosaccharides and preparation method therefor

A technology of Morinda officinalis oligosaccharide and Morinda officinalis, applied in the field of medicine, can solve the problems of complex preparation process and low yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

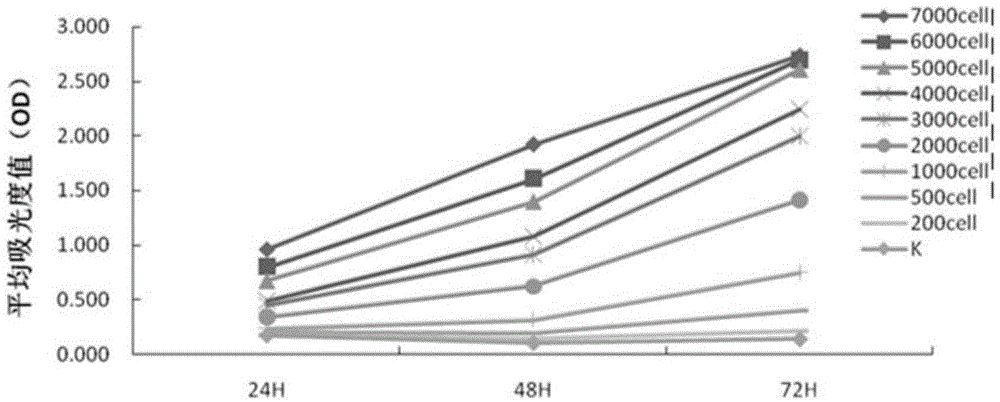

Image

Examples

Embodiment 1

[0162] 500g of Morinda officinalis medicinal material, crushed into coarse powder, add 6 times the amount of water to extract three times, each time for 1h, combine the extracts, concentrate to 500mL, the relative density is about 1.2g / mL. Let cool, add 95% ethanol to ethanol concentration of 60%, let it stand overnight, filter, recover ethanol, concentrate to 250mL, relative density is about 1.4g / mL. Add water to dilute to 1L, add 100g activated carbon to absorb overnight, filter, and the filtrate is absorbed by D101 macroporous resin column, eluted with water for 4 column volumes, combined eluents, concentrated and then freeze-dried to obtain the total extract of Morinda officinalis oligosaccharides 217g, Morinda officinalis oligosaccharides 205g, including disaccharides 14.94g, trisaccharides 9.14g, tetrasaccharides 13.00g, pentasaccharides 12.98g.

Embodiment 2

[0164] 500g of Morinda officinalis medicinal material, crushed into coarse powder, added 7 times the amount of water to extract three times, 1.5h each time, combined the extracts, concentrated to 500mL, and the relative density was about 1.2g / mL. Let it cool, add 95% ethanol until the ethanol concentration is 65%, let stand overnight, filter, recover ethanol, concentrate to 250mL, and the relative density is about 1.4g / mL. Add water to dilute to 1L, add 150g activated carbon to absorb overnight, filter, and the filtrate is absorbed by D101 macroporous resin column, eluted with water for 5 column volumes, combined eluents, concentrated and freeze-dried to obtain the total extract of Morinda officinalis oligosaccharides 209g, Morinda officinalis oligosaccharides 207g, including disaccharides 18.63g, trisaccharides 14.49g, tetrasaccharides 18.62g, pentasaccharides 18.57g.

Embodiment 3

[0166]500g of Morinda officinalis medicinal material, crushed into coarse powder, added 8 times the amount of water to extract three times, 2 hours each time, combined the extracts, concentrated to 500mL, and the relative density was about 1.2g / mL. Let cool, add 95% ethanol to ethanol concentration of 70%, let it stand overnight, filter, recover ethanol, concentrate to 250mL, relative density is about 1.4g / mL. Add water to dilute to 1L, add 200g activated carbon to adsorb overnight, filter, and the filtrate is adsorbed by D101 macroporous resin column, eluted with water for 6 column volumes, combined eluents, concentrated and then freeze-dried to obtain the total extract of Morinda officinalis oligosaccharides 201g, Morinda officinalis oligosaccharides 161g, including 9.67g disaccharides, 8.05g trisaccharides, 8.05g tetrasaccharides, and 8.07g pentasaccharides.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com