Zsm-5/silicalite-1 core-shell molecular sieves with shell-oriented epitaxial intergrowth

A core-shell molecular sieve and epitaxial symbiosis technology, which is applied in the direction of molecular sieve catalysts, bulk chemical production, chemical/physical processes, etc., can solve the problem of waste of shell raw materials and templates, poor catalyst activity and stability, and non-epitaxial symbiosis of shells and other problems, to achieve the effect of simplifying the preparation method, simplifying the symbiosis control of orientation and epitaxy, and having a strong tendency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Dissolve 360 grams of silica sol (wt.40%) in 200 grams of water to configure solution A; dissolve 7 grams of aluminum sulfate in 100 grams of water to configure solution B; dissolve 3 grams of potassium sulfate in 240 grams of water to configure into solution C. Slowly add solution B to solution A dropwise, stir well, then add solution C, the formed reaction mixture is crystallized at 170°C for 2 days, filtered, and dried at low temperature to obtain large-grain nuclear phase ZSM-5 molecular sieves.

[0023] 320 grams of unroasted ZSM-5 raw powder is used as a nuclear phase molecular sieve, with a molar silicon-aluminum ratio of 100, added to 0.05 mol / liter urea aqueous solution, heated to 80°C under stirring and kept for 2 hours, filtered and heated at 120°C The ZSM-5 nuclear phase molecular sieve after outer surface treatment is obtained by drying in the air atmosphere.

[0024] 120 grams of white carbon black, 10 grams of silicon tetrafluoride, 800 grams of tetrae...

Embodiment 2

[0026] Dissolve 600 grams of water glass in 900 grams of water to form solution A; dissolve 25 grams of aluminum sulfate in 300 grams of water to form solution B; dissolve 20 grams of sodium sulfate in 200 grams of water to form solution C. Slowly add solution B to solution A dropwise, stir well, then add solution C, and the formed reaction mixture is crystallized at 140°C for 4 days, filtered, and dried at low temperature to obtain a small-grain nuclear phase ZSM-5 molecular sieve.

[0027] 40 grams of unroasted ZSM-5 raw powder is used as a nuclear phase molecular sieve, with a molar silicon-aluminum ratio of 40, added to a 0.05 mol / liter HMT aqueous solution, heated to 90°C under stirring and kept for 3 hours, filtered and cooled in 120°C air The ZSM-5 nuclear phase molecular sieve after the outer surface treatment is obtained by drying in the atmosphere.

[0028] 35 grams of TEOS, 6 grams of TPABr, and 180 milliliters of water were uniformly stirred to form a gel to obtain...

Embodiment 14-19

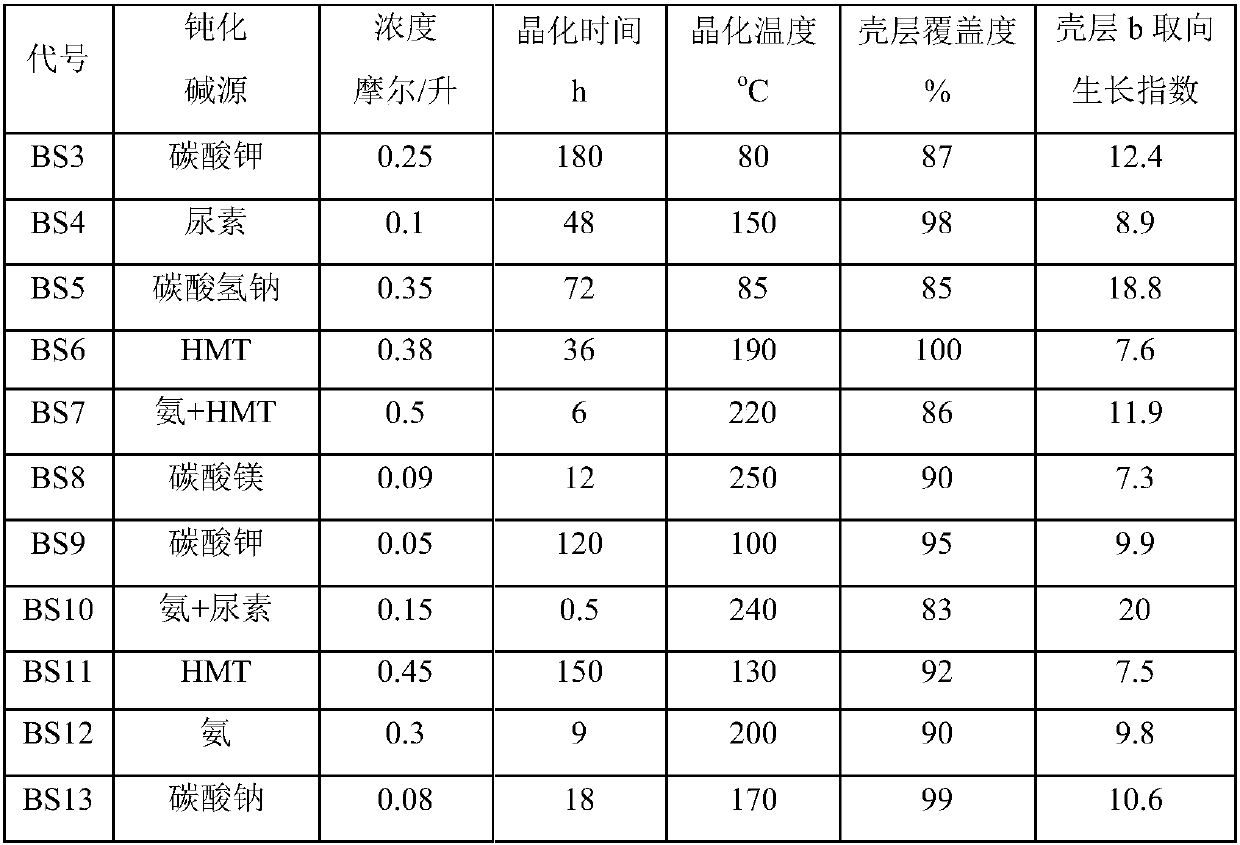

[0041] In Examples 14 to 19, samples BS-1 and BS-2 of core-shell molecular sieves BS-1 and BS-2 were used as catalysts for the production of p-xylene, respectively, with shell-oriented epitaxial symbiosis ZSM-5 / silicalite-1 core-shell molecular sieve samples. The results are shown in Table 2.

[0042] Table 2

[0043]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com