ZSM-5/silicalite-1 core-shell molecular sieve for shell layer with oriented epitaxial intergrowth

A ZSM-5, core-shell molecular sieve technology, used in molecular sieve catalysts, bulk chemical production, chemical/physical processes, etc., can solve the problem of shell raw materials, template waste, poor catalyst activity and stability, and shell mechanical strength. It can achieve the effect of simplifying the preparation method, simplifying the symbiosis control of orientation epitaxy, and saving raw materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

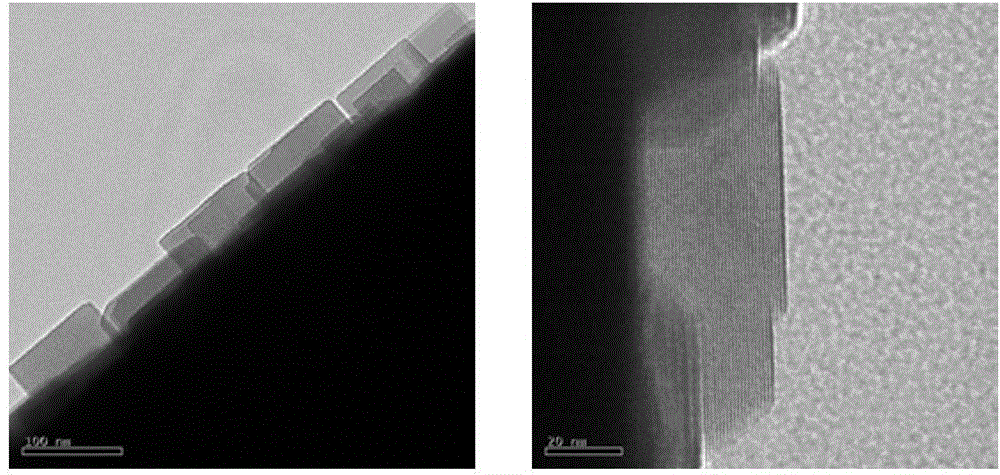

Image

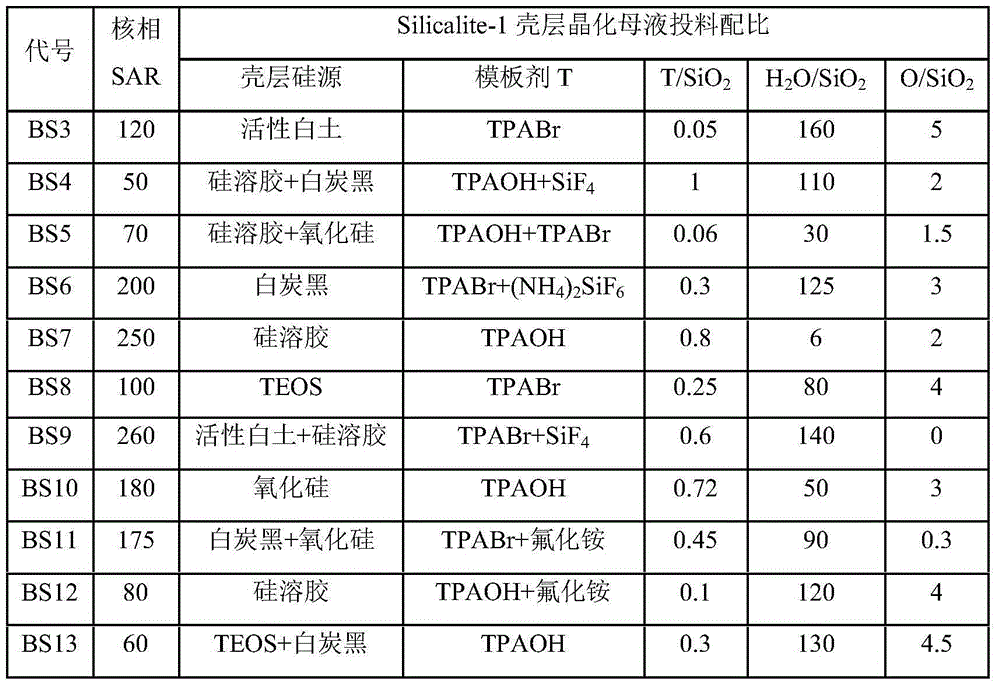

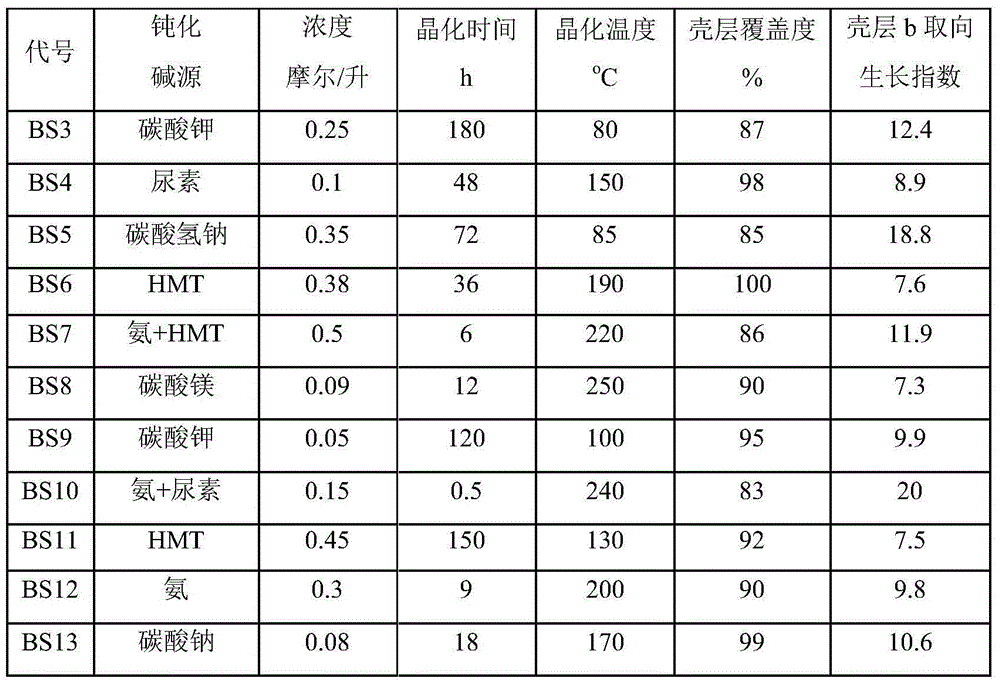

Examples

Embodiment 1

[0022] Dissolve 360 grams of silica sol (wt.40%) in 200 grams of water to configure solution A; dissolve 7 grams of aluminum sulfate in 100 grams of water to configure solution B; dissolve 3 grams of potassium sulfate in 240 grams of water to configure into solution C. Slowly add solution B to solution A dropwise, stir well, then add solution C, the formed reaction mixture is crystallized at 170°C for 2 days, filtered, and dried at low temperature to obtain large-grain nuclear phase ZSM-5 molecular sieves.

[0023] 320 grams of unroasted ZSM-5 raw powder is used as a nuclear phase molecular sieve, with a molar silicon-aluminum ratio of 100, added to 0.05 mol / liter urea aqueous solution, heated to 80°C under stirring and kept for 2 hours, filtered and heated at 120°C The ZSM-5 nuclear phase molecular sieve after outer surface treatment is obtained by drying in the air atmosphere.

[0024] 120 grams of white carbon black, 10 grams of silicon tetrafluoride, 800 grams of tetrae...

Embodiment 2

[0026] Dissolve 600 grams of water glass in 900 grams of water to form solution A; dissolve 25 grams of aluminum sulfate in 300 grams of water to form solution B; dissolve 20 grams of sodium sulfate in 200 grams of water to form solution C. Slowly add solution B to solution A dropwise, stir well, then add solution C, and the formed reaction mixture is crystallized at 140°C for 4 days, filtered, and dried at low temperature to obtain a small-grain nuclear phase ZSM-5 molecular sieve.

[0027] 40 grams of unroasted ZSM-5 raw powder is used as a nuclear phase molecular sieve, with a molar silicon-aluminum ratio of 40, added to a 0.05 mol / liter HMT aqueous solution, heated to 90°C under stirring and kept for 3 hours, filtered and cooled in 120°C air The ZSM-5 nuclear phase molecular sieve after the outer surface treatment is obtained by drying in the atmosphere.

[0028] 35 grams of TEOS, 6 grams of TPABr, and 180 milliliters of water were uniformly stirred to form a gel to obtain...

Embodiment 14-19

[0041] In Examples 14 to 19, samples BS-1 and BS-2 of core-shell molecular sieves BS-1 and BS-2 were used as catalysts for the production of p-xylene, respectively, with shell-oriented epitaxial symbiosis ZSM-5 / silicalite-1 core-shell molecular sieve samples. The results are shown in Table 2.

[0042] Table 2

[0043]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com