Zsm-11/silicalite-2 core-shell molecular sieve with dense shell and preparation method thereof

A ZSM-11, core-shell molecular sieve technology, applied in molecular sieve catalysts, molecular sieve characteristic polymorphic crystalline silicon, chemical instruments and methods, etc., can solve the problems of complex shell structure modulation and unsatisfactory control effects, and achieve simplification control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] 320 grams of ZSM-11 (dried and unroasted, molar silicon-aluminum ratio of 100) raw powder is used as a nuclear phase molecular sieve, added to 0.05 mol / liter urea aqueous solution, and the temperature is raised to 80 under stirring o C and kept for 2 hours, filtered and heated at 120 o C drying in an air atmosphere to obtain the ZSM-11 nuclear phase molecular sieve after the outer surface treatment.

[0022] 120 grams of white carbon black, 10 grams of phenyltrimethylammonium chloride (BTMACl), 800 grams of tetrabutylammonium hydroxide and 6000 milliliters of water were evenly stirred to form a gel to obtain the silicalite-2 shell crystallization mother liquor, and slowly added while stirring The ZSM-11 nuclear phase molecular sieve powder after the above-mentioned weak base passivation treatment was stirred and aged for 2 hours and then 500 grams of glycerin was added. 160 o The molecular sieve sample obtained by static crystallization in oven C for 30 hours, filtere...

Embodiment 2

[0024] 40 grams of ZSM-11 (dried and unroasted, molar silicon-aluminum ratio of 40) raw powder is used as a nuclear phase molecular sieve, added to 0.05 mol / liter HMT aqueous solution, and the temperature is raised to 90 under stirring o C and kept for 3 hours, filtered and heated at 120 o C drying in an air atmosphere to obtain the ZSM-11 nuclear phase molecular sieve after the outer surface treatment.

[0025] 35 grams of TEOS, 6 grams of TBABr, and 180 milliliters of water were evenly stirred to form a gel to obtain the silicalite-2 shell crystallization mother liquor, and the ZSM-11 nuclear phase molecular sieve powder after the above treatment was slowly added while stirring, and then added after stirring and aging for 1 hour 10 grams of ethanol, the mixed system was quickly moved into the polytetrafluoroethylene-lined stainless steel coat crystallization kettle, placed in 180 o The molecular sieve sample obtained by static crystallization in oven C for 24 hours was take...

Embodiment 3~15

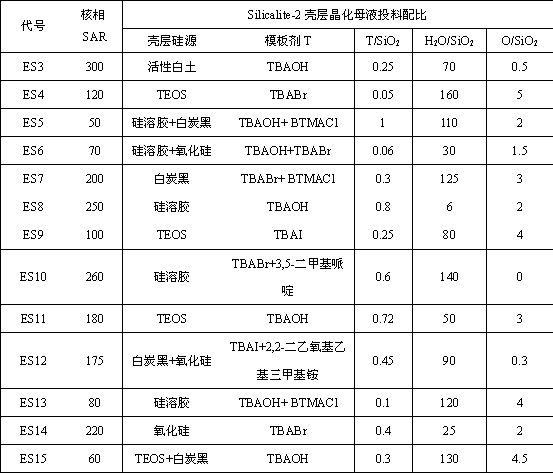

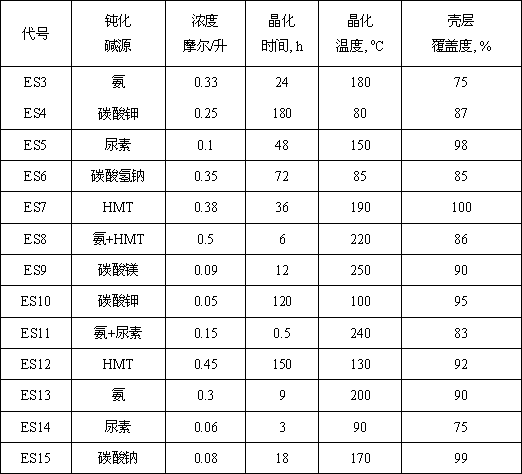

[0027] Examples 3-15 are ZSM-11 / silicalite-2 core-shell molecular sieves ES3-15 synthesized according to the similar conditions and method steps of Example 1 with the raw material ratio and synthetic materials in Table 1, see Table 1 for details.

[0028] Table 1

[0029]

[0030] Table 1 (continued)

[0031]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com