Method of manufacturing dense nano granular film and ordered nanowire film by using coffee-ring effects

A nanoparticle and silver nanoparticle technology, which is used in the preparation of thin films, dense nanoparticles and ordered nanowire films, can solve the problems of demanding equipment and operation precision, cumbersome and complicated preparation processes, etc., and achieve low cost and easy operation. Simple, versatile effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

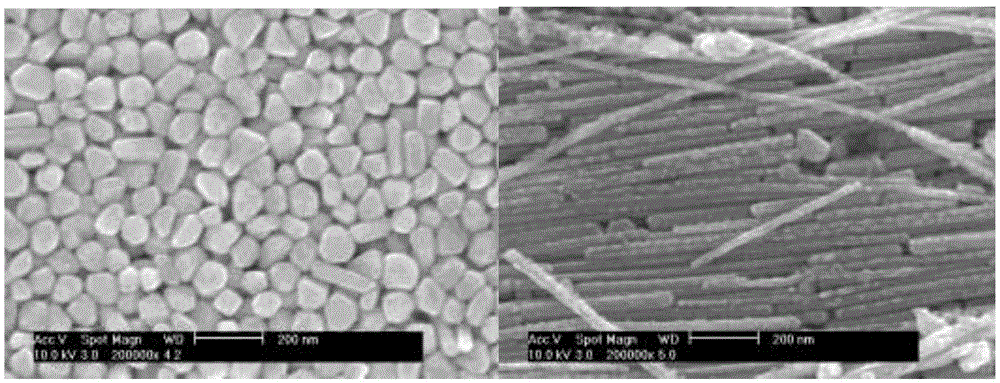

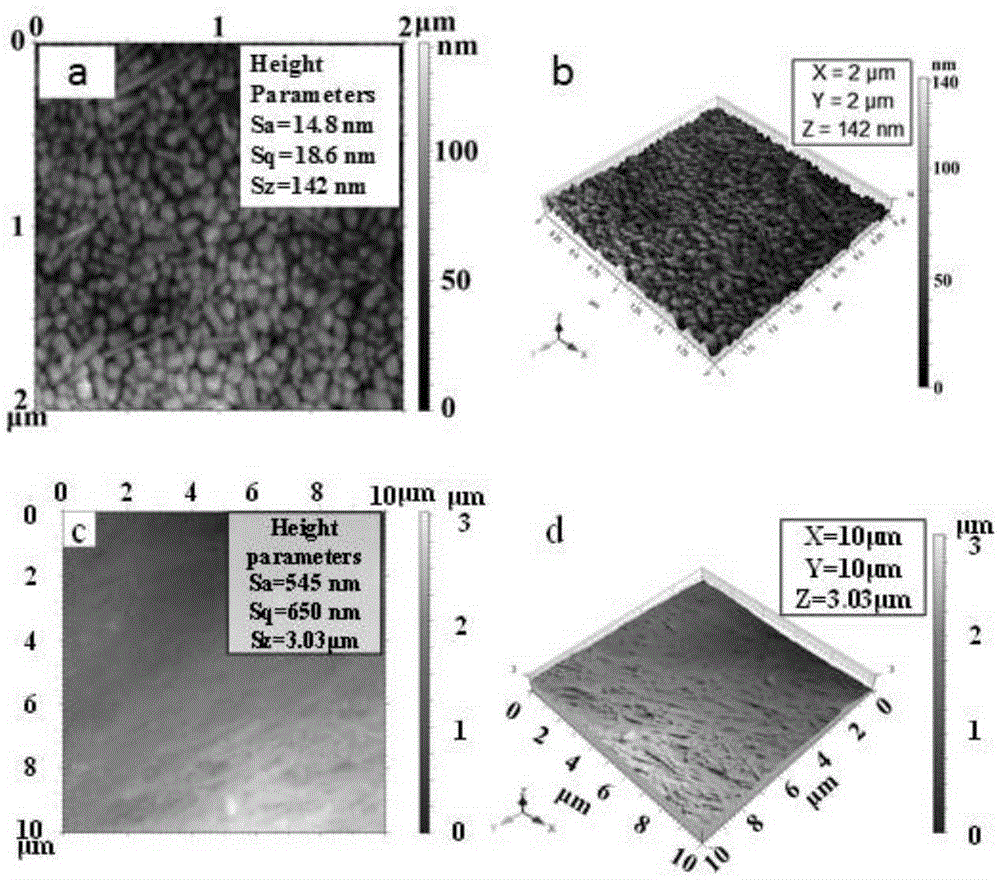

[0028] Embodiment 1, the preparation of compact silver nanoparticle film

[0029] 1) Dissolve 52.9 mg of trisodium citrate in 10 ml of water

[0030] 2) Dissolve 42.5 mg of silver nitrate in 250 ml of water, and heat to 85° C. with constant stirring.

[0031] 3) Pour the solution in step 1) into solution 2) and continue heating to 90-95°C. Keep warm for about 45 minutes. A silver nanoparticle solution was obtained after cooling.

[0032] 4) The silver nanoparticle solution obtained in step 3) is concentrated two hundred times by a centrifuge.

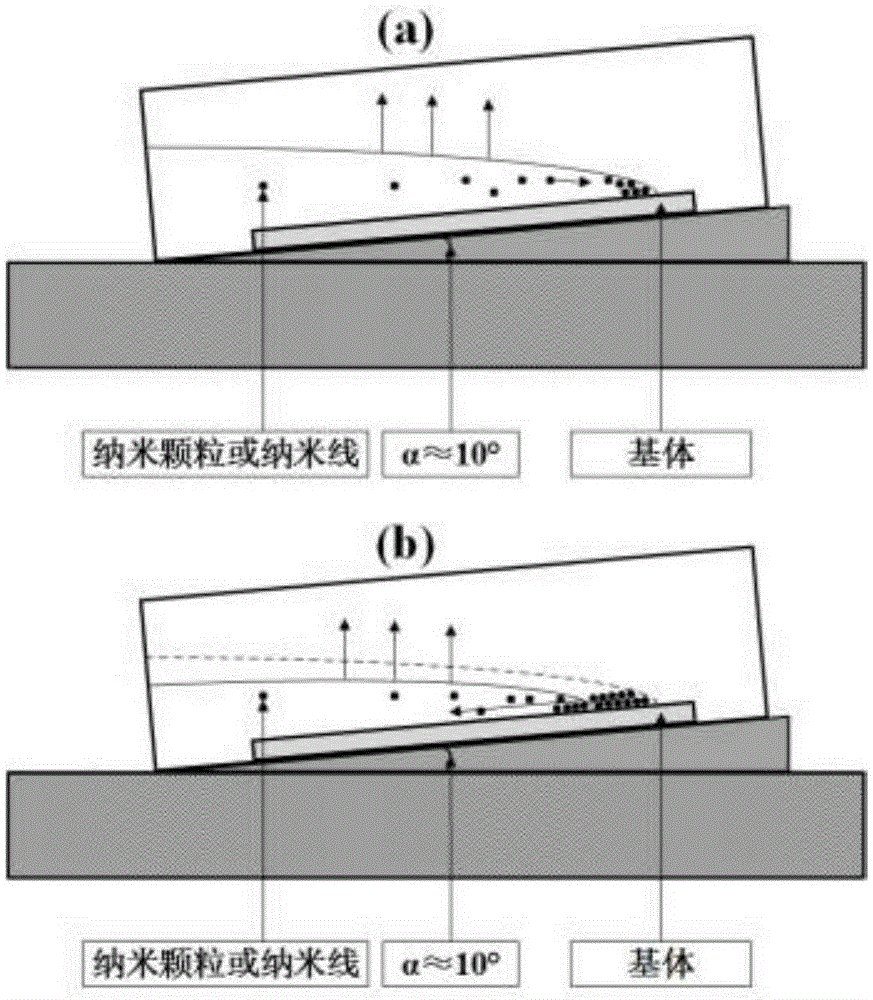

[0033] 5) Put the silicon wafers on which the nanomaterials need to be deposited into containers of corresponding size. And place it on an inclined platform with an inclination angle of about 10 degrees.

[0034] 6) Pour the nanoparticle solution concentrated in step 4) and immerse to the height of the substrate. Put the whole container into an oven and heat it to 50 degrees Celsius until the solution is completely evaporated to d...

Embodiment 2

[0036] Embodiment 2, the preparation of ordered silver nanowire film

[0037] 1) Select ethylene glycol as a solvent to prepare a silver nitrate solution with a concentration of 0.9 moles per liter, a sodium chloride solution with a concentration of 0.01 moles per liter, and a PVP (K90) solution with a concentration of 2.7 moles per liter.

[0038] 2) Measure 1 milliliter of silver nitrate solution and 0.6 milliliter of sodium chloride solution into 18.4 milliliters of PVP solution. Mix and stir and heat to 185°C for 20 minutes.

[0039] 3) The nanowire mixed solution prepared in step 2) was added into deionized water at a volume ratio of 1:1, washed, and centrifuged to obtain a pure nanowire solution.

[0040] 4) The silver nanoparticle solution obtained in step 3) is concentrated two hundred times by a centrifuge.

[0041] 5) Put the silicon wafers on which the nanomaterials need to be deposited into containers of corresponding size. And place it on an inclined platform w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com