Hydrothermal synthesis preparation method of zinc doped superparamagnetic ferroferric oxide nano particle

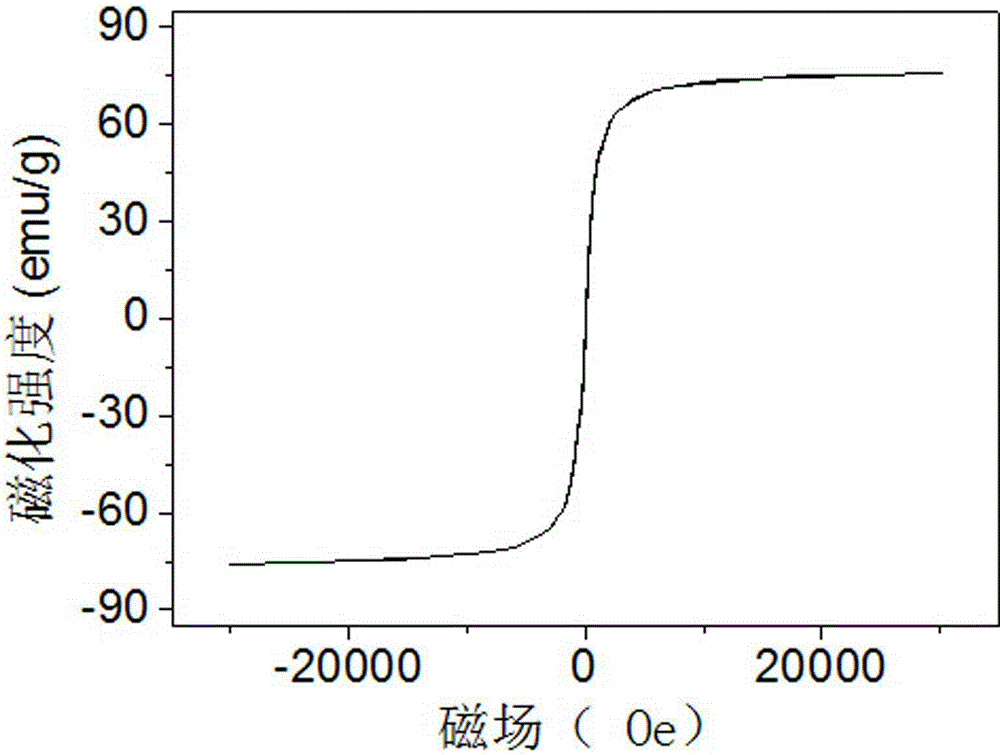

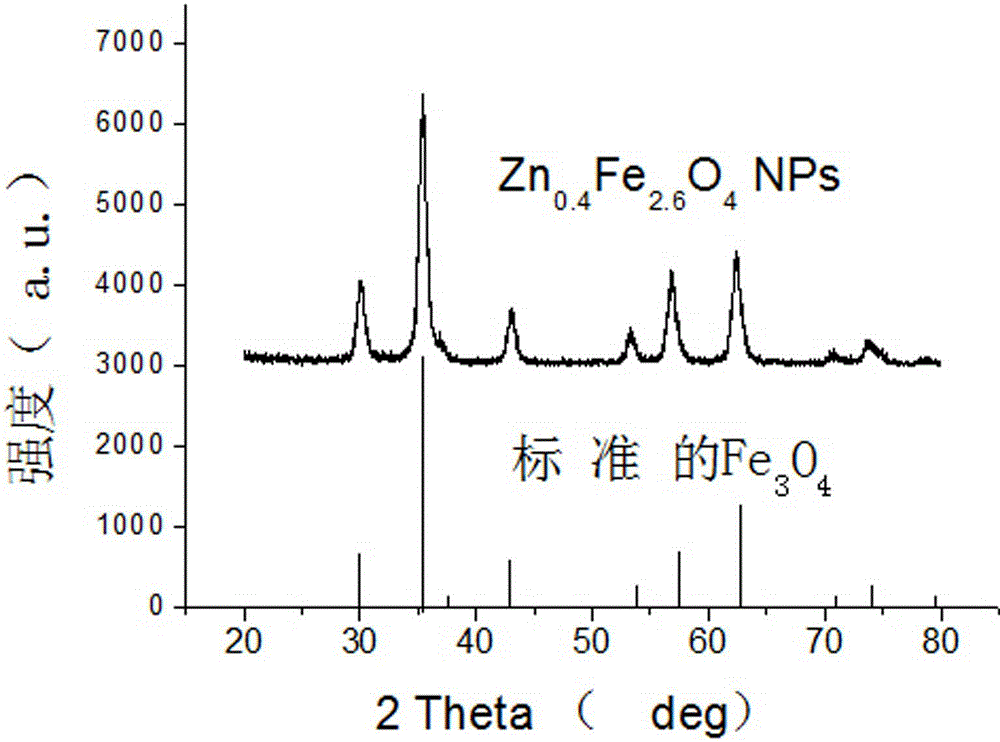

A technology of ferroferric oxide and nanoparticles, which is applied in the field of nano-biomedical materials, can solve the problems of low product crystallinity and low magnetic saturation value, and achieve the effect of simple preparation method, high crystallinity, and satisfying production and application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

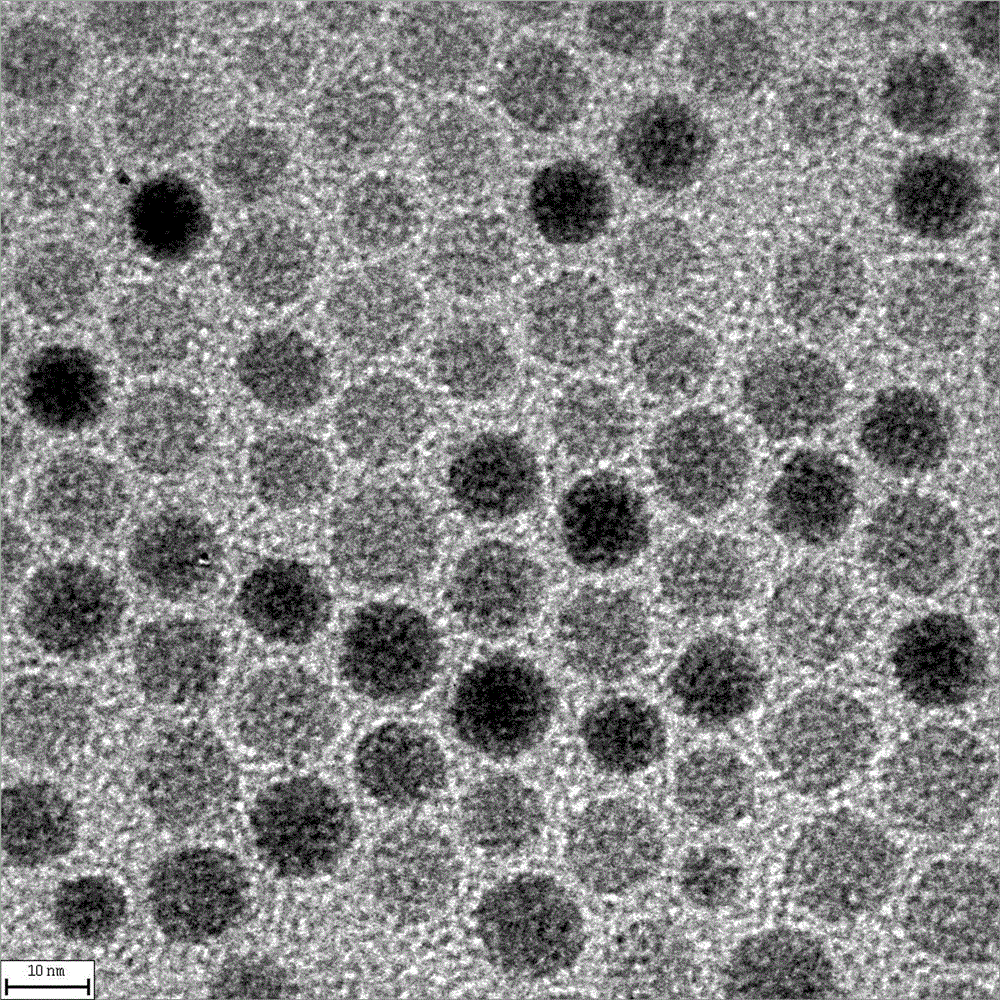

Embodiment 1

[0025] FeSO 4 ·(NH 4 ) 2 SO 4 ·6H 2 O and ZnSO 4 Dissolve in 20ml of water so that the precursor reaches 1.73×10 -3 molFe 2+ and2.67×10 -4 mol Zn 2+ the goal of. Next, mix 10ml of oleic acid, 10ml of water and 1g of NaOH, and stir magnetically at room temperature until a homogeneous solution is obtained. Furthermore, the precursor Fe 2+ and Zn 2+ Pour into this homogeneous solution, and after stirring for a few minutes, the mixed solution turns dark brown. Finally, the solution was transferred into a 50ml reaction kettle, sealed, and heated at 230 degrees for 15 hours. After the reaction, cool to room temperature. The product is deposited at the bottom of the kettle, and the nanoparticles are taken out by dissolving with cyclohexane. Then add ethanol into the cyclohexane containing the nanoparticles to precipitate the nanoparticles, and finally wash the nanoparticles repeatedly with ethanol several times. The organic surfactant on the particle surface was double...

Embodiment 2

[0027] FeSO 4 ·(NH 4 ) 2 SO4 ·6H 2 O and ZnSO 4 Dissolve in 20ml of water so that the precursor reaches 1.87×10 -3 molFe 2+ and1.33×10 -4 mol Zn 2+ the goal of. Next, mix 10ml of oleic acid, 10ml of water and 1g of NaOH, and stir magnetically at room temperature until a homogeneous solution is obtained. Furthermore, the precursor Fe 2+ and Zn 2+ Pour into this homogeneous solution, and after stirring for a few minutes, the mixed solution turns dark brown. Finally, the solution was transferred into a 50ml reaction kettle, sealed, and heated at 230 degrees for 15 hours. After the reaction, cool to room temperature. The product is deposited at the bottom of the kettle, and the nanoparticles are taken out by dissolving with cyclohexane. Then add ethanol into the cyclohexane containing the nanoparticles to precipitate the nanoparticles, and finally wash the nanoparticles repeatedly with ethanol several times. The organic surfactant on the particle surface was double-e...

Embodiment 3

[0029] FeSO 4 ·(NH 4 ) 2 SO 4 ·6H 2 O and ZnSO 4 Dissolve in 20ml of water so that the precursor reaches 1.67×10 -3 molFe 2+ and3.33×10 -4 mol Zn 2+ the goal of. Next, mix 10ml of oleic acid, 10ml of water and 1g of NaOH, and stir magnetically at room temperature until a homogeneous solution is obtained. Furthermore, the precursor Fe 2+ and Zn 2+ Pour into this homogeneous solution, and after stirring for a few minutes, the mixed solution turns dark brown. Finally, the solution was transferred into a 50ml reaction kettle, sealed, and heated at 230 degrees for 15 hours. After the reaction, cool to room temperature. The product is deposited at the bottom of the kettle, and the nanoparticles are taken out by dissolving with cyclohexane. Then add ethanol into the cyclohexane containing the nanoparticles to precipitate the nanoparticles, and finally wash the nanoparticles repeatedly with ethanol several times. The organic surfactant on the particle surface was double...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com