A kind of magnetic conductive graphene battery material and preparation method thereof

A battery material, graphene technology, applied in the direction of battery electrodes, secondary batteries, inorganic material magnetism, etc., can solve problems such as thermodynamic instability, achieve excellent electrical properties, high magnetic saturation value effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

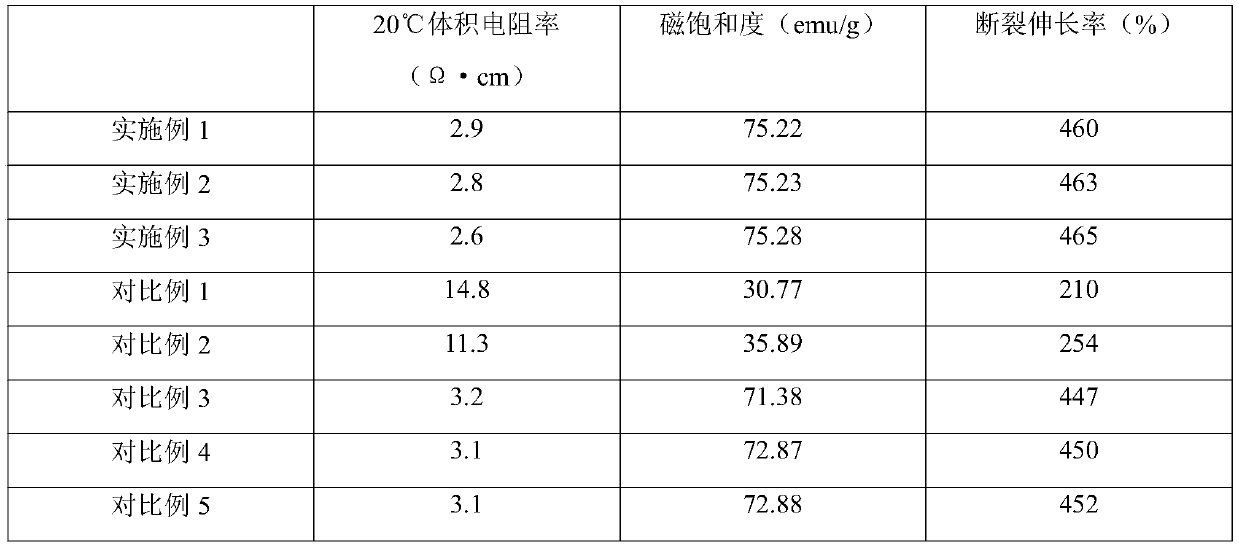

Examples

Embodiment 1

[0033] A preparation method of a magnetically conductive graphene battery material, comprising the following steps:

[0034] (1) adding ferric salt with a particle size of 20nm and heat-treated liquid polyacrylonitrile into the solvent, stirring and mixing to obtain liquid polyacrylonitrile-coated iron particles;

[0035] (2) Dry at 200°C for 5 hours until the solvent is completely evaporated to obtain low-temperature carbonized precursor-coated iron particles;

[0036] (3) under the protection of an inert atmosphere, calcining at 1000° C. for 5 hours to obtain graphene coated with nano-iron particles;

[0037] (4) adding nickel salt with a particle size of 20nm, polyethylene oxide-polypropylene oxide-polyethylene oxide triblock copolymer, sodium phytate, sodium thimerosal and coated nano-iron particles to the volume In the ethylene glycol solution with a concentration of 30%, after ultrasonic dispersion, transfer to a hydrothermal high-pressure reactor, and react at 200 ° C ...

Embodiment 2

[0044] A preparation method of a magnetically conductive graphene battery material, comprising the following steps:

[0045] (1) adding ferric salt with a particle diameter of 30nm and heat-treated liquid polyacrylonitrile into the solvent, stirring and mixing to obtain liquid polyacrylonitrile-coated iron particles;

[0046] (2) Dry at 250°C for 8 hours until the solvent is completely evaporated to obtain low-temperature carbonized precursor-coated iron particles;

[0047] (3) under the protection of an inert atmosphere, calcining at 1200° C. for 8 hours to obtain graphene coated with nano-iron particles;

[0048] (4) adding nickel salt with a particle size of 30nm, polyethylene oxide-polypropylene oxide-polyethylene oxide triblock copolymer, sodium phytate, sodium thimerosal and coated nano-iron particles into the volume In the ethylene glycol solution with a concentration of 40%, after ultrasonic dispersion, transfer to a hydrothermal high-pressure reactor, and react at 220°...

Embodiment 3

[0055] A preparation method of a magnetically conductive graphene battery material, comprising the following steps:

[0056] (1) adding ferric salt with a particle diameter of 25nm and heat-treated liquid polyacrylonitrile into the solvent, stirring and mixing to obtain liquid polyacrylonitrile-coated iron particles;

[0057] (2) Dry at 220°C for 6 hours until the solvent is completely evaporated to obtain low-temperature carbonized precursor-coated iron particles;

[0058] (3) Under the protection of an inert atmosphere, calcining at 1100° C. for 7 hours to obtain graphene coated with nano-iron particles;

[0059] (4) adding nickel salt with a particle diameter of 25nm, polyethylene oxide-polypropylene oxide-polyethylene oxide triblock copolymer, sodium phytate, sodium thimerosal and coated nano-iron particles into the volume In the ethylene glycol solution with a concentration of 35%, after ultrasonic dispersion, transfer to a hydrothermal high-pressure reactor, and react a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com