A light-weight block prepared from "phosphorus solid waste" as raw material and its preparation method

A technology for phosphorus solid waste and raw materials, applied in the field of building materials, can solve the problems of low excitation rate, inability to give full play to the potential activity of phosphorus tailings, slow activation of activity, etc., and achieves low production cost, broad market application prospects, and utilization rate of waste. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

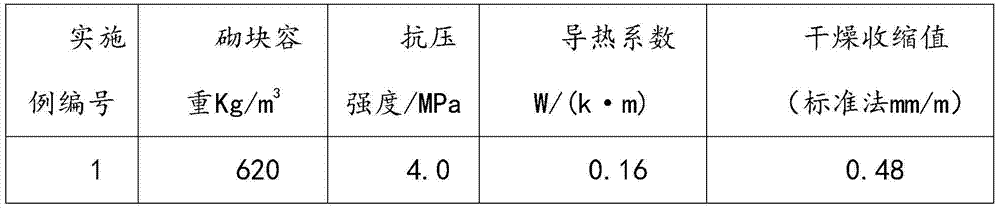

Embodiment 1

[0029] According to the technical scheme of the present invention, a light-weight building block material is prepared. In parts by weight, its components are 60.1 parts of phosphorous tailings, 15.0 parts of carbide slag, 15.0 parts of coal gangue, 2.0 parts of phosphogypsum, and 7.0 parts of cement. 2.0 parts of aluminum powder, 0.5 parts of polymerized polyol grinding aid, 0.4 parts of polycarboxylate superplasticizer, and water-to-material ratio of 0.65.

[0030] Specific preparation method:

[0031] (1) Weigh calcium carbide slag, phosphorus tailings, phosphogypsum, and coal gangue according to the above ratio, and place them in a crusher to crush until the average particle size is 2-20 mm.

[0032] (2) Put the above crushed material in a wet mill, add water and 0.5 parts of grinding aid according to the ratio of water to material 0.65, and ball mill for 5 hours until the specific surface area is 350-1200m 2 In the range of / kg, the average particle diameter is in the range...

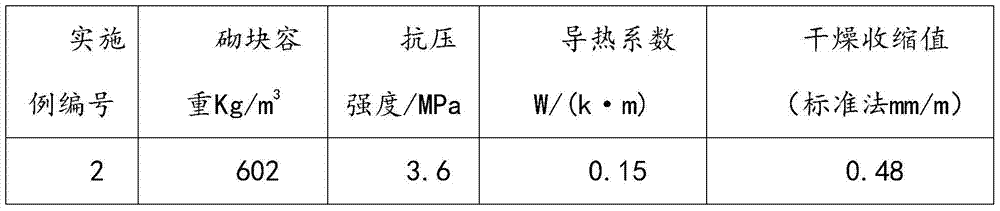

Embodiment 2

[0037] According to the technical scheme of the present invention, a light-weight building block material is prepared, and its components are 55.0 parts of phosphorous tailings, 14.0 parts of carbide slag, 23.4 parts of steel slag, 3.0 parts of phosphogypsum, and 6.0 parts of cement in parts by weight. , 2.4 parts of aluminum powder, 0.45 parts of triisopropanolamine grinding aid, 0.7 parts of melamine-based water reducer, and a water-to-material ratio of 0.6.

[0038] Specific preparation method:

[0039] (1) Weigh calcium carbide slag, phosphorus tailings, phosphogypsum, and steel slag according to the above ratio, and place them in a crusher to crush until the average particle size is 2-20mm.

[0040] (2) Put the above crushed material in a wet mill, add water and 0.45 parts of grinding aid according to the ratio of water to material 0.6, and ball mill for 5 hours until the specific surface area is 350-1200m 2 In the range of / kg, the average particle diameter is in the ra...

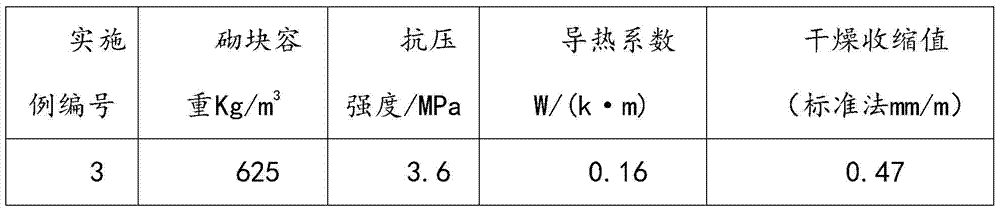

Embodiment 3

[0045] According to the technical scheme of the present invention, a light-weight block material has been prepared. In parts by weight, its components are 65.0 parts of phosphorus tailings, 10.0 parts of carbide slag, 8 parts of coal gangue, 4.3 parts of fly ash, phosphorus 3.0 parts of gypsum, 6.0 parts of cement, 2.0 parts of aluminum powder, 0.5 parts of triethanolamine type grinding aid, 0.5 part of melamine type water reducer, and the ratio of water to material is 0.7.

[0046] Specific preparation method:

[0047] (1) Weigh calcium carbide slag, phosphorus tailings, phosphogypsum, and coal gangue according to the above ratio, and place them in a crusher to crush until the average particle size is 2-20mm.

[0048] (2) Put the above crushed material in a wet mill, add water, 0.5 parts of grinding aid, fly ash, and ball mill for 5.5 hours according to the ratio of water to material ratio of 0.7, until the specific surface area is 350-1200m 2 In the range of / kg, the averag...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com