Washing-free foam printing paste and printing method

A technology of printing color paste and printing method, which is applied in the field of textile printing and dyeing, can solve problems such as difficult wastewater treatment and environmental pollution, achieve water saving and energy saving economic benefits, improve printing quality, and be beneficial to environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

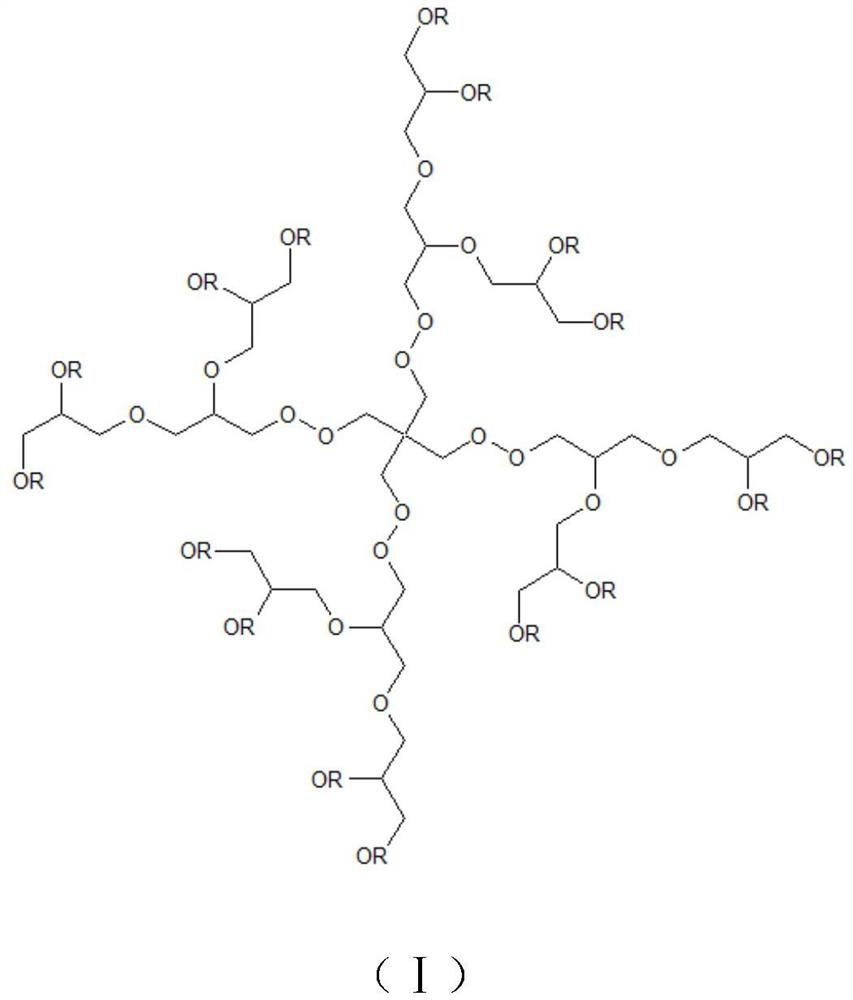

[0027] The preparation process of the hyperbranched polyester thickener is as follows: put 1 part of pentaerythritol and 4 parts of bismethylol propionic acid into the reaction kettle, then put in the catalyst toluenesulfonic acid, react at 150°C for 1 hour, and then put in 8 parts Two methylolpropionic acid, the product is obtained after the reaction.

[0028] Wherein, the high-performance foam stabilizer is at least one of linear azobenzene polyoxyethylene ether PEP-600, azobenzene polyoxyethylene ether PIP-1000, and sodium lauryl sulfate.

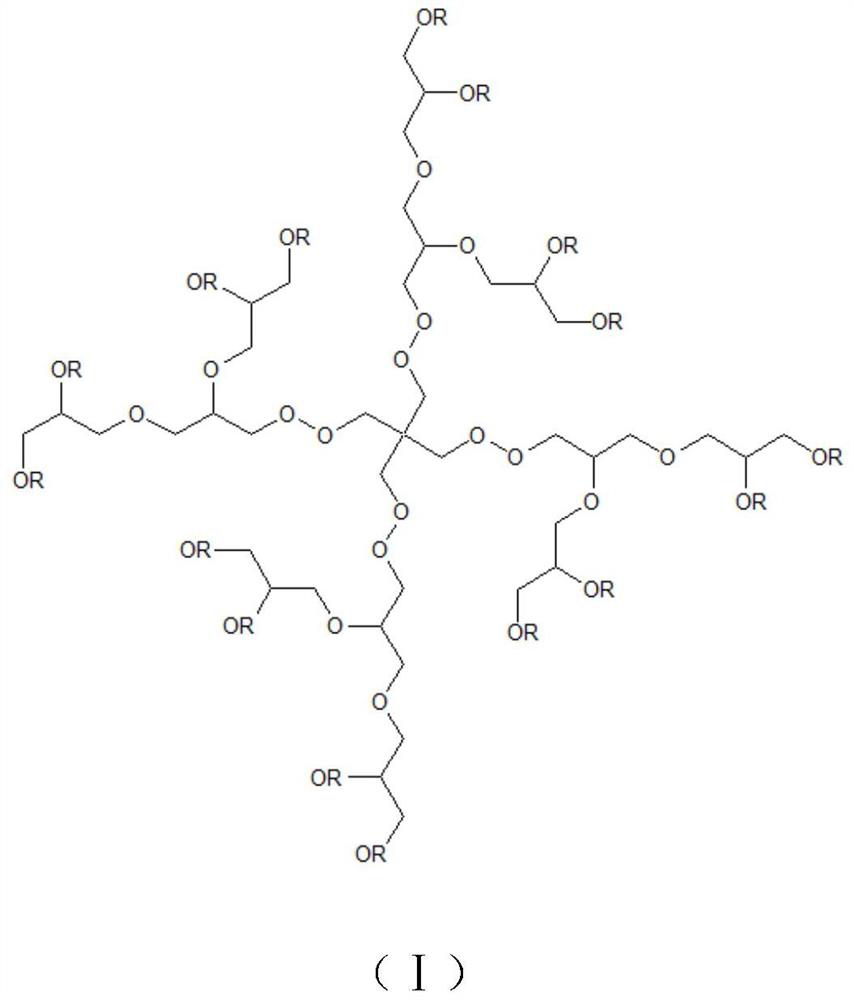

[0029] The molecular structural formula of the linear azobenzene polyoxyethylene ether PEP-600 is shown in formula (II).

[0030]

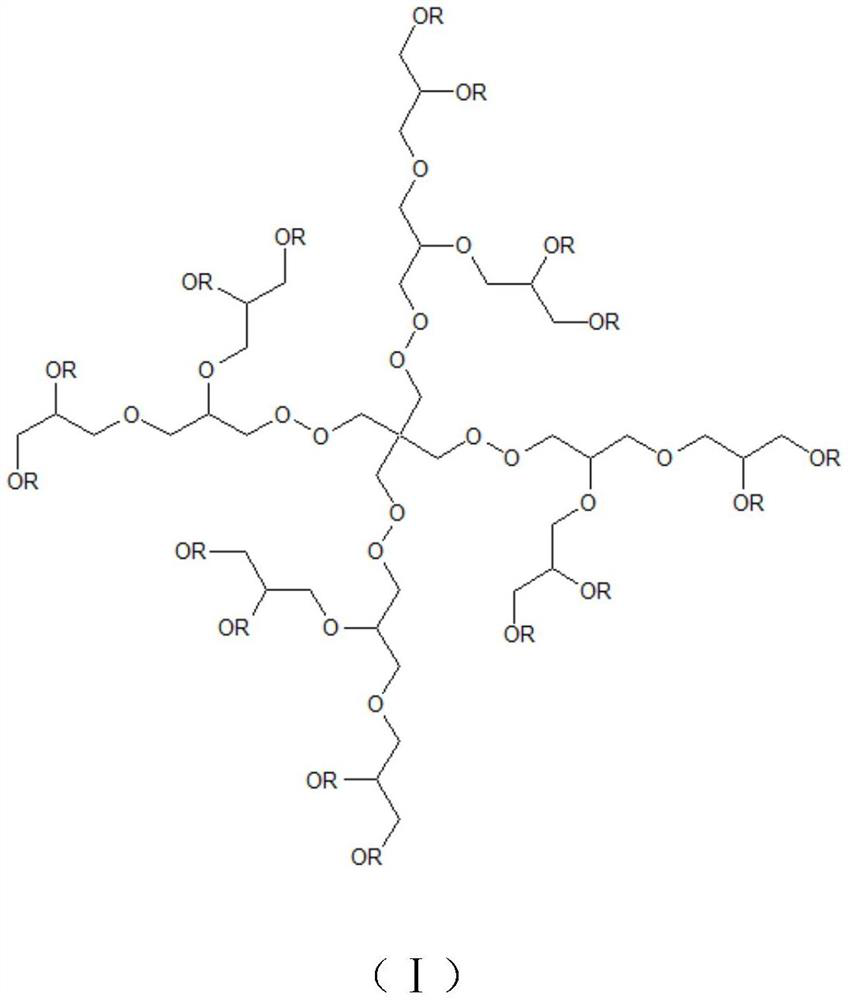

[0031] The molecular structural formula of the azobenzene polyoxyethylene ether PIP-1000 is shown in formula (III).

[0032]

[0033] Wherein, the composite foaming agent is azodicarbonamide.

[0034] The present invention also provides a printing method using the above-mentioned water-free foam prin...

Embodiment 1

[0038] The non-washing foam printing color paste of the present embodiment 1 comprises the following components according to the mass percentage: nanometer liquid dispersion black MX-DBN 6%, PEP-600 0.5%, azodicarbonamide 1.5%, thickener 2%, remove Ionized water balance. The above-mentioned components were weighed according to the above-mentioned mass percentages, and all the components were stirred and mixed evenly to obtain the water-free printing color paste.

[0039] The method for carrying out foam printing using the water-free foam printing color paste of the present embodiment 1 comprises the following steps:

[0040] (1) Add the water-free foam printing color paste to the foaming machine for foaming to make printing foam. The printing foam is transported from the duct of the foaming machine to the foam applicator, and the foam applicator is used to accurately supply the liquid, and then the printing foam is sprayed with a scraper. uniformly distributed on the surface ...

Embodiment 2

[0043] The non-washing foam printing color paste of the present embodiment 2 comprises the following components according to mass percentage: nanometer liquid dispersion blue MX-2R 6%, PIP-1000 1%, azodicarbonamide 2%, thickener 2%, remove Ionized water balance. The above-mentioned components were weighed according to the above-mentioned mass percentages, and all the components were stirred and mixed evenly to obtain the water-free printing color paste.

[0044] The method for carrying out foam printing using the water-free foam printing color paste of the present embodiment 2 comprises the following steps:

[0045] (1) Add the water-free foam printing color paste to the foaming machine for foaming to make printing foam. The printing foam is transported from the duct of the foaming machine to the foam applicator, and the foam applicator is used to accurately supply the liquid, and then the printing foam is sprayed with a scraper. uniformly distributed on the surface of the fa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com