A kind of magnesium phosphate cement-based rapid repair mortar and preparation method thereof

A magnesium phosphate cement and repair mortar technology, which is applied in the field of magnesium phosphate cement-based rapid repair mortar and its preparation, can solve problems such as insufficient water resistance, and achieve the effects of improved performance indicators, controllable setting time, and high water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

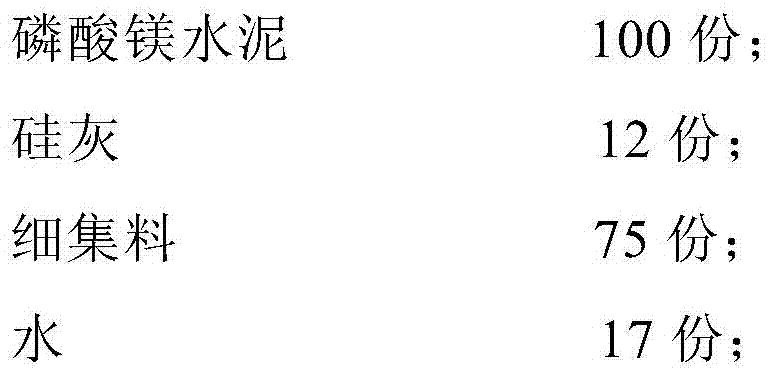

[0040] A magnesium phosphate cement-based rapid repair mortar, comprising the following components in parts by weight:

[0041]

[0042] Magnesium phosphate cement is made by mixing 66.5 parts by weight of metal oxide powder, 24 parts of phosphate, 5 parts of retarder and 4.5 parts of setting adjustment components. The metal oxide powder is dead-burned magnesium oxide powder with a purity of more than 90%, fineness less than 200 mesh, phosphate is potassium dihydrogen phosphate, industrial grade product, purity greater than 98%, retarder borax, industrial grade product, purity greater than 98%, coagulation adjustment component is K 2 HPO 4, The fine aggregate is a mixture of river sand and quartz sand with a fineness modulus of 2 to 3 and a maximum particle size of 4.75 mm.

[0043] The described rapid repair mortar is prepared through the following steps: weighing various raw materials according to the above-mentioned proportions, adding retarder borax, K 2 HPO 4 Dissol...

Embodiment 2

[0045] A magnesium phosphate cement-based rapid repair mortar, comprising the following components in parts by weight:

[0046]

[0047] Magnesium phosphate cement is made by mixing 60 parts by weight of metal oxide powder, 28 parts of phosphate, 6 parts of retarder and 6 parts of setting adjustment components. The metal oxide powder is dead-burned magnesium oxide powder with a purity greater than 90%, fineness less than 200 mesh, phosphate is potassium dihydrogen phosphate, industrial grade product, purity greater than 98%, retarder borax, industrial grade product, purity greater than 98%, coagulation adjustment component is K 2 HPO 4 ·3H 2 O, the fine aggregate is machine-made sand with a fineness modulus of 2 to 3 and a maximum particle size of 4.75 mm.

[0048] Weigh various raw materials according to the above proportions, mix evenly with reference to the preparation method of Example 1, and obtain a magnesium phosphate cement-based rapid repair mortar with excellent...

Embodiment 3

[0050] A magnesium phosphate cement-based rapid repair mortar, comprising the following components in parts by weight:

[0051]

[0052] Magnesium phosphate cement is made by mixing 70 parts by weight of metal oxide powder, 20 parts of phosphate, 5 parts of retarder and 5 parts of setting adjustment components. The metal oxide powder is dead-burned magnesium oxide powder with a purity greater than 90%, fineness less than 200 mesh, phosphate is potassium dihydrogen phosphate, industrial grade product, purity greater than 98%, retarder borax, industrial grade product, purity greater than 98%, coagulation adjustment component is K 2 HPO 4 ·3H 2 O and K 2 HPO 4 It is mixed at a mass ratio of 1:1, and the fine aggregate is river sand with a fineness modulus of 2 to 3 and a maximum particle size of 4.75mm.

[0053] Weigh various raw materials according to the above proportions, and mix them evenly with reference to Example 1 to obtain a magnesium phosphate cement-based rapid ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com