An integral pouring method for preparing foamed wall building materials made of recycled solid waste

A solid waste, integral pouring technology, applied in the field of building materials, can solve problems such as waste of resources, inability to drill nails, air pollution, etc., and achieve the effects of reducing pollution, reducing labor force, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

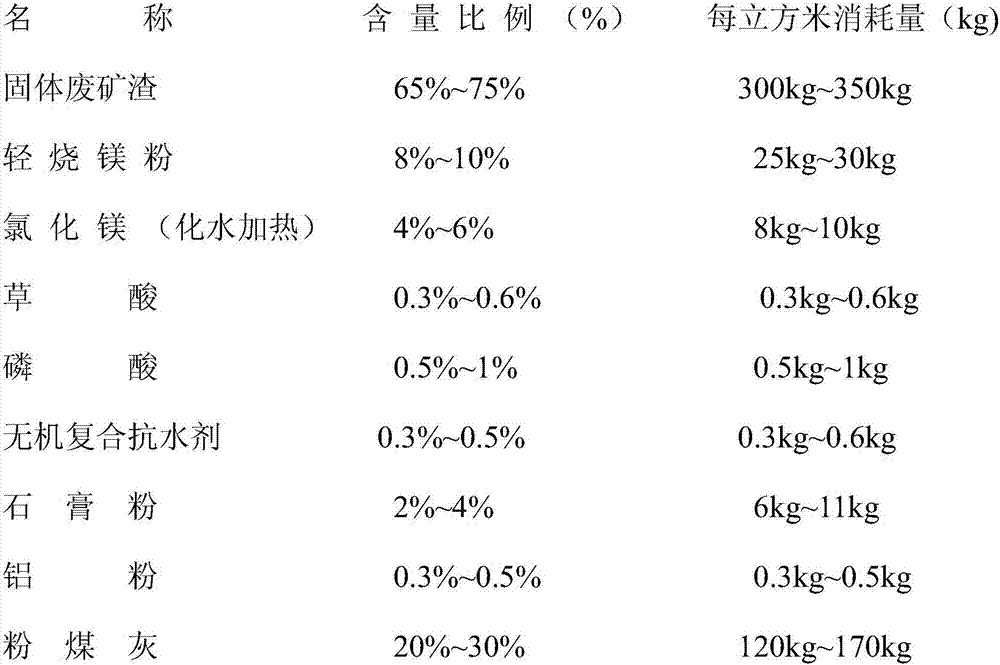

[0009] Embodiment 1: The formula percentage per cubic base material of the whole block casting is as follows:

[0010]

[0011] The overall casting block is equipped with a large mold, after heating the above-mentioned content of magnesium chloride water to 70°C, under the stirring of a strong mixer, add the above-mentioned content of light-burned magnesium powder, phosphoric acid, oxalic acid, and composite water-resistant agent , gypsum powder, aluminum powder, fly ash, and construction waste (or solid waste slag) are stirred vigorously for 6 minutes to make the base material evenly decompose, expand instantly, and then pour it into a pre-designed mold to solidify itself Physically forming, forming The final strength is above 8.2mpa, the compressive strength is high, the thermal conductivity reaches 0.27, the thermal insulation performance is good, the weight is light, the durability is good, the service life is long, easy to process, can be cut, can be nailed, and can be ...

Embodiment 2

[0013] The formula and percentage by weight of the base material per cubic meter of the overall casting block are as follows: 55% to 65% of construction waste (or solid waste slag), 8% to 10% of lightly burned magnesium powder, and magnesium chloride (heated to 70 degrees Celsius in liquefied water). ) 3% to 6%, phosphoric acid 0.5% to 1%, oxalic acid 0.3% to 0.6%, inorganic composite water-resistant agent 0.3% to 0.5%, gypsum powder 2% to 4%, aluminum powder 0.3% to 0.5%, pulverized coal Ash 20% to 30%.

[0014] The integral cast block is fixed by a mould, and the above-mentioned content of magnesium chloride water is heated to 70°C under the stirring of a strong mixer, and the above-mentioned content of light-burned magnesium powder, phosphoric acid, oxalic acid, inorganic composite water-resistant agent, and gypsum are added. powder, aluminum powder, fly ash or construction waste and stir vigorously for 6 minutes. Make the substrate evenly decompose, expand instantly, and ...

example 1

[0017] The specifications of the wall tiles are 24mm long, 11.5mm wide and 5.1mm thick.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com