Ordinary calcium superphosphate feeding, screening, crushing system

A superphosphate and crushing system technology, applied in grain processing, etc., can solve the problems of high labor intensity of operators, unsmooth system, and many fault points, so as to avoid extrusion collision and large vibration, reduce labor intensity and The effect of high production cost and product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

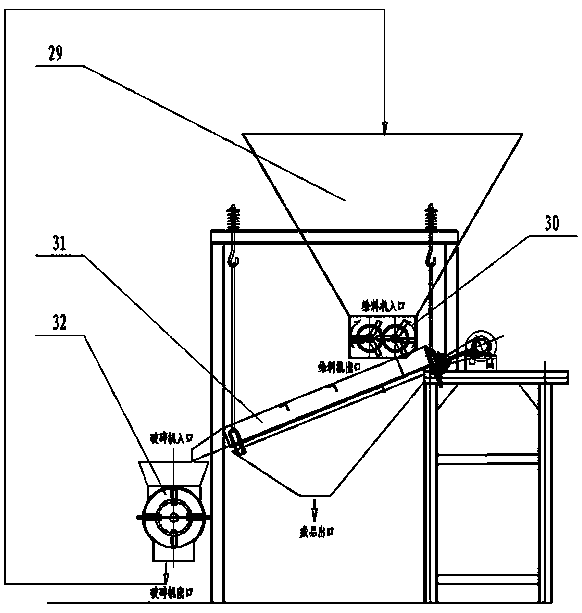

[0026] Such as figure 1 As shown, the present invention includes a feeding system 30 , a screening system 31 and a crushing system 32 . The material in the silo 29 is dropped to the feeding system 30 by gravity, and the feeding system 30 evenly feeds the material to the screening system 31, and after reciprocating screening, the finished product is transported to the automatic packaging system. The remaining large particle materials enter the crushing system 32 for crushing, and then enter the feed bin 29 again.

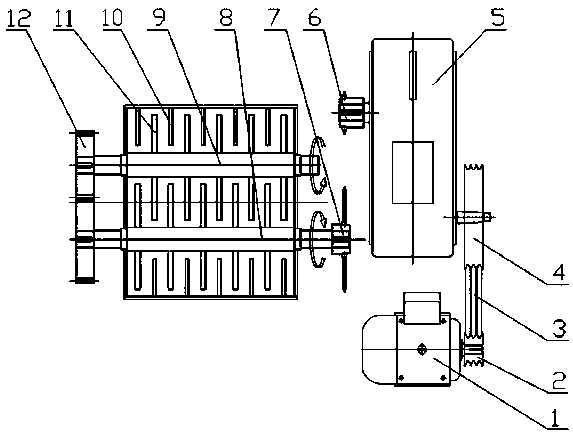

[0027] Such as figure 2 As shown, the motor-1 of the feeding system is connected with the driven sprocket 7 through a chain through the motor pulley-2, the belt-3, the reducer pulley 4, the reducer 5, and the drive sprocket 6 successively, and the driven sprocket 7 is fixed On the driving shaft 8, the two gears 12 on the driving shaft 8 and the driven shaft 9 mesh with each other. The driving shaft 8 and the driven shaft 9 are connected to the tank with the cleani...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com