Limestone powder metering and feeding device

A technology of feeding device and limestone powder, which is applied in the direction of conveyor control device, packaging, transportation and packaging, etc., can solve the problem of limited blade diameter, achieve the effect of precisely controlling the feeding amount, avoiding moisture failure, and feeding thoroughly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

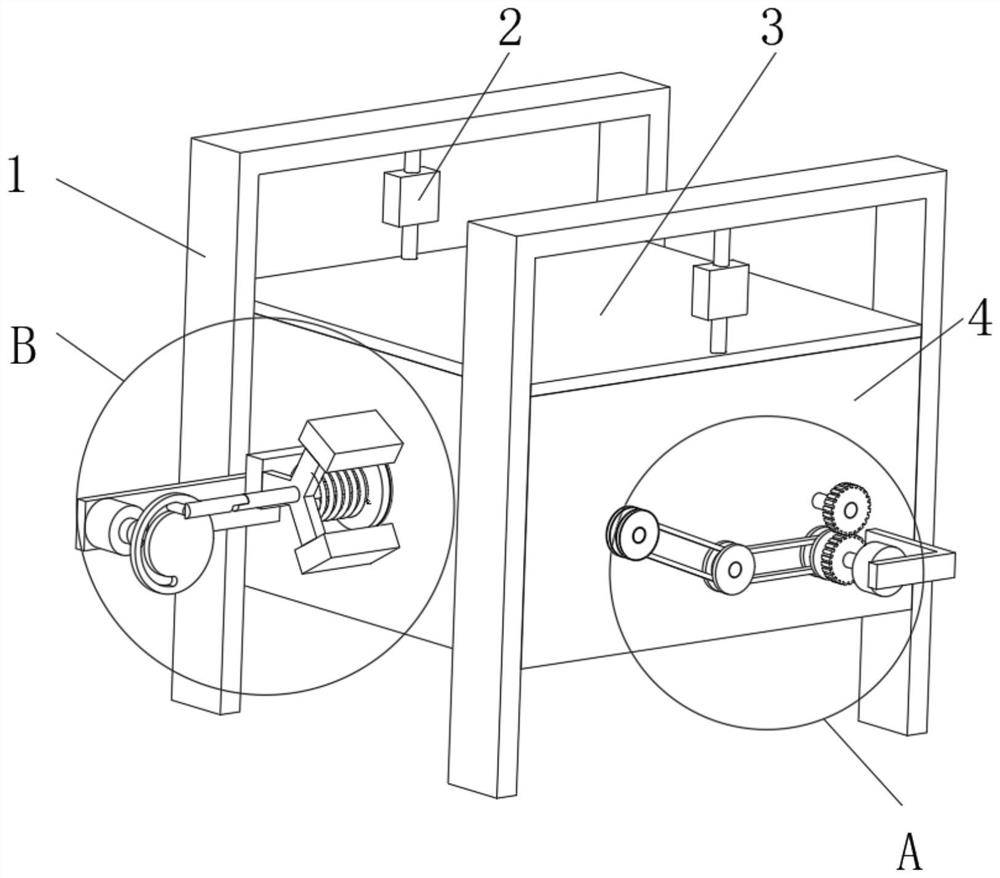

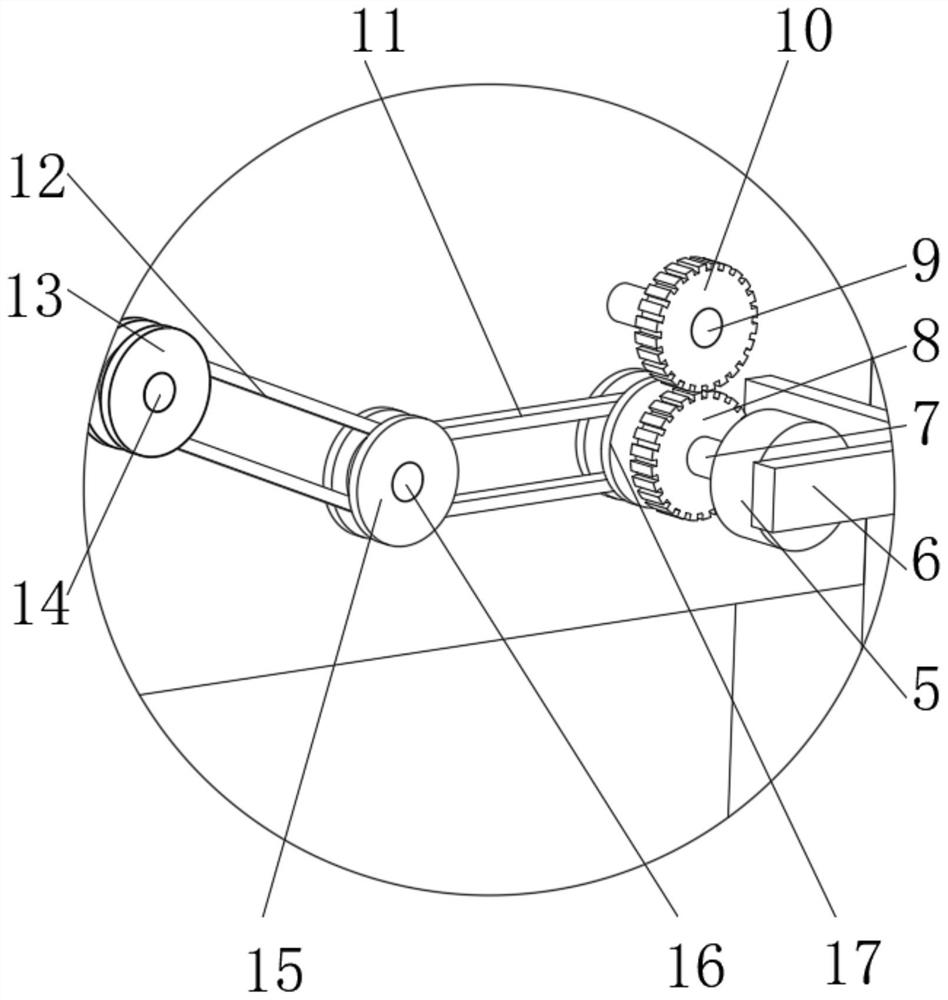

[0032] A limestone powder metering and feeding device, such as figure 1 As shown, including the gantry 1, the inner walls of the two gantry 1 are slidably connected with the same feed bin 4, and the top outer wall of the feed bin 4 is fixed with a top cover 3 by bolts, and the two gantries 1 and the top cover 3 The outer walls of the opposite side are all provided with electronic weighing devices 2, and the two outer walls perpendicular to each other of the feed bin 4 are respectively provided with a linkage mechanism and a vibrating device, and the inner wall of the feed bin 4 is provided with a feeding mechanism; when the present embodiment is used, the Limestone powder is put into the silo 4 in advance. Since the silo 4 is fixedly connected to the top cover 3 and the gantry 1, the two ends of the electronic weighing device 2 are connected to the top cover 3 and the gantry 1 respectively. The electronic weighing device 2 can calculate and display the weight of the silo 4, th...

Embodiment 2

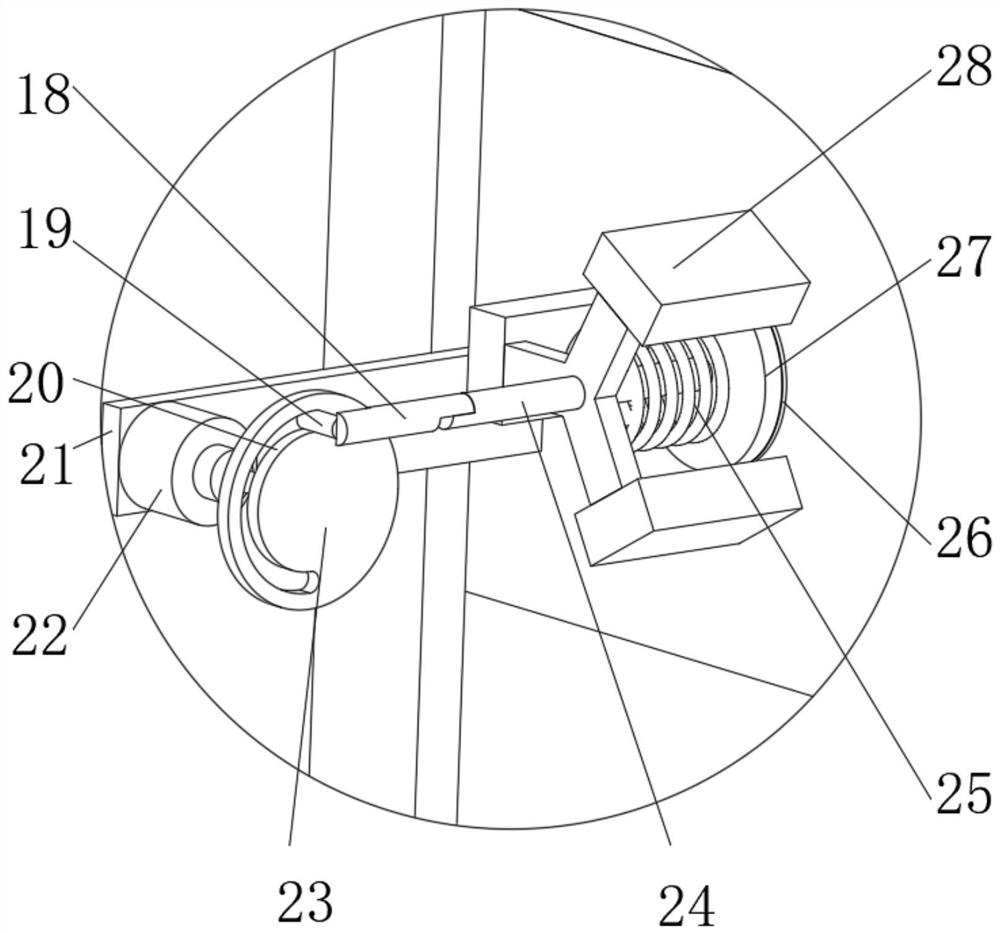

[0038] A limestone powder metering and feeding device, such as figure 1 , 3 As shown, in order to solve the problem of sticking to the inner wall of the bin 4 which is difficult to clean due to damp deterioration; this embodiment makes the following improvements on the basis of Embodiment 1: the vibrating device includes a spring 25 and a vibrating hammer 27, and the bin 4 A third support 28 is fixedly installed on one side of the outer wall, and the inner wall of the third support 28 is slidably connected with a slide bar 24. The vibration hammer 27 is fixedly installed on the side outer wall of the slide bar 24 close to the feed bin 4, and the vibration hammer 27 is close to the feed bin. 4 is bonded with a rubber pad 26 on one side of the outer wall, and the outer walls on both sides of the spring 25 are respectively arranged on the outer walls of the opposite side of the shock hammer 27 and the third bracket 28, and the top outer wall of the slide bar 24 is hinged with a h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com