Propylene oxide production method

A technology of propylene oxide and production method, applied in the production field of propylene oxide, can solve the problem of high energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

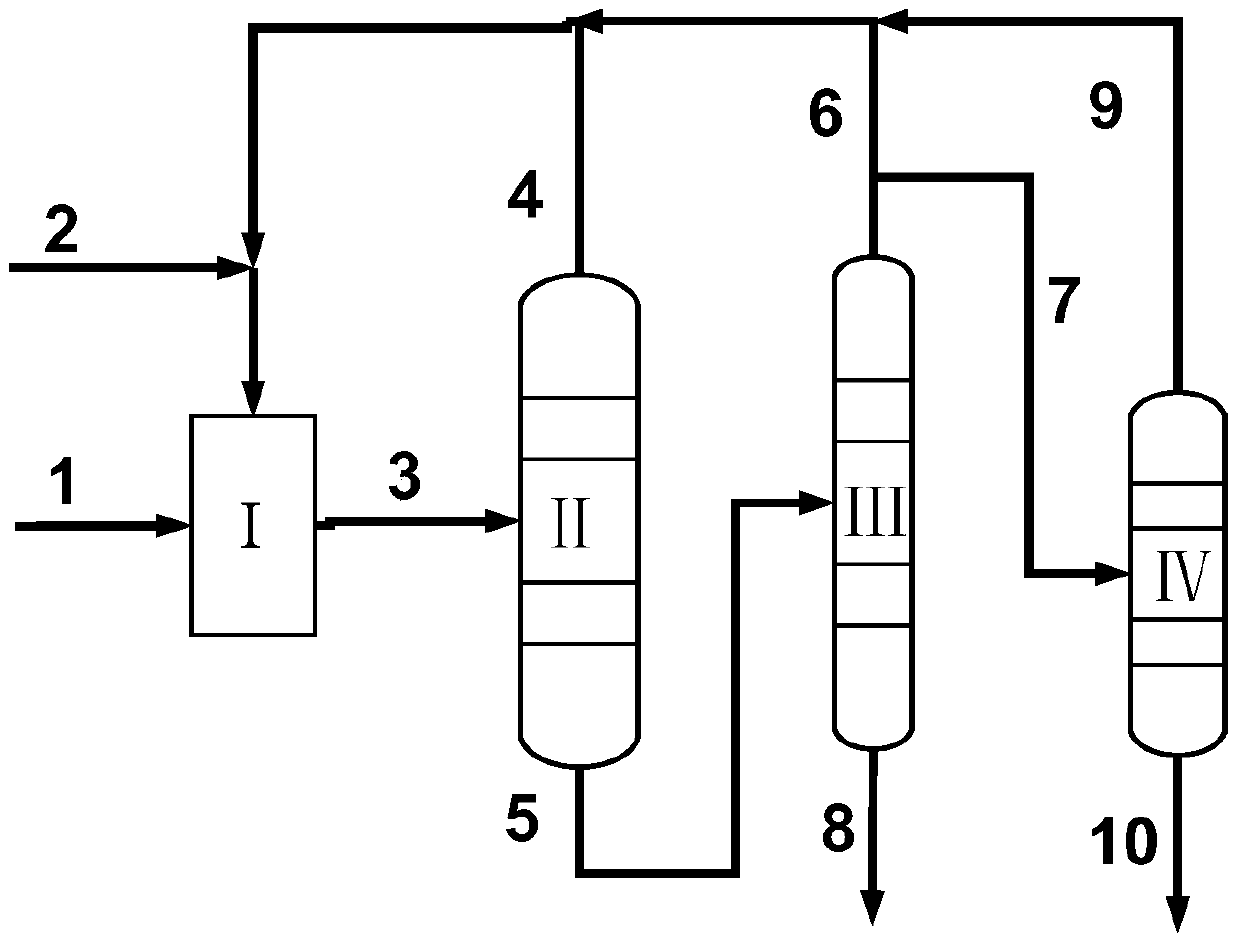

[0028] Such as figure 1 As shown, taking a 100,000-ton / year PO plant as an example, the raw materials cumene hydroperoxide 1 and fresh propylene 2 are reacted in reactor I to produce α,α-dimethylbenzyl alcohol, cumene, and cyclohexane. Liquid phase stream 3 of oxypropane, propylene and propane. Stream 3 is sent to high-pressure propylene recovery tower II for separation, and stream 4 is obtained at the top of the tower, and stream 5 containing α,α-dimethylbenzyl alcohol, cumene, propylene oxide, a small amount of propylene and propane is obtained from the bottom of the tower. Stream 5 is sent to low-pressure propylene recovery tower III for separation, and stream 6 is obtained at the top of the tower, and crude propylene oxide product stream 8 from which propylene has been removed is obtained from the tower bottom. The propylene stream 6 recovered at the top of the low-pressure propylene recovery tower III is divided into two parts, and a part of the stream 7 enters the de-pro...

Embodiment 2

[0037] Same as [Example 1], except that the operating conditions are changed.

[0038] In liquid stream 3, the content of α,α-dimethylbenzyl alcohol is 26% by weight, the content of cumene is 21.5%, the content of propylene oxide is 10.5%, and the content of propylene is 39%. , The content of propane is 2%. The operating conditions of the high-pressure propylene recovery tower are: the operating pressure is 1.6MPa, the operating temperature at the top of the tower is 40°C, the operating temperature of the tower bottom is 87°C, and the number of theoretical plates is 25.

[0039] The operating conditions of the low pressure propylene recovery tower are as follows: operating pressure is 0.2MPa, tower top operating temperature is -20°C, tower bottom operating temperature is 120°C, and the number of theoretical plates is 20.

[0040] The operating conditions of the de-propanizer are as follows: operating pressure is 2.0MPa, operating temperature at the top of the tower is 51°C, operatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com