Carbide-containing austempered ductile iron and preparation method thereof

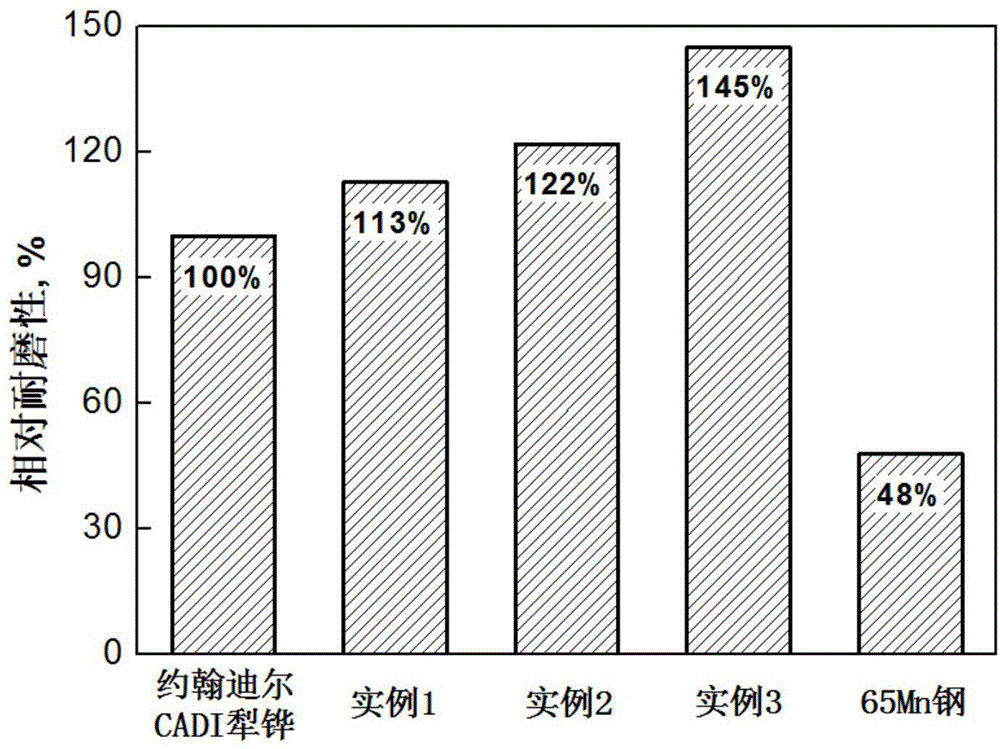

A nodular cast iron and austempering technology, applied in the field of nodular cast iron, can solve problems such as difficult control of structure uniformity and stability, difficult production process operation, and improved wear resistance, achieving low cost, simple selection, and improved wear resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

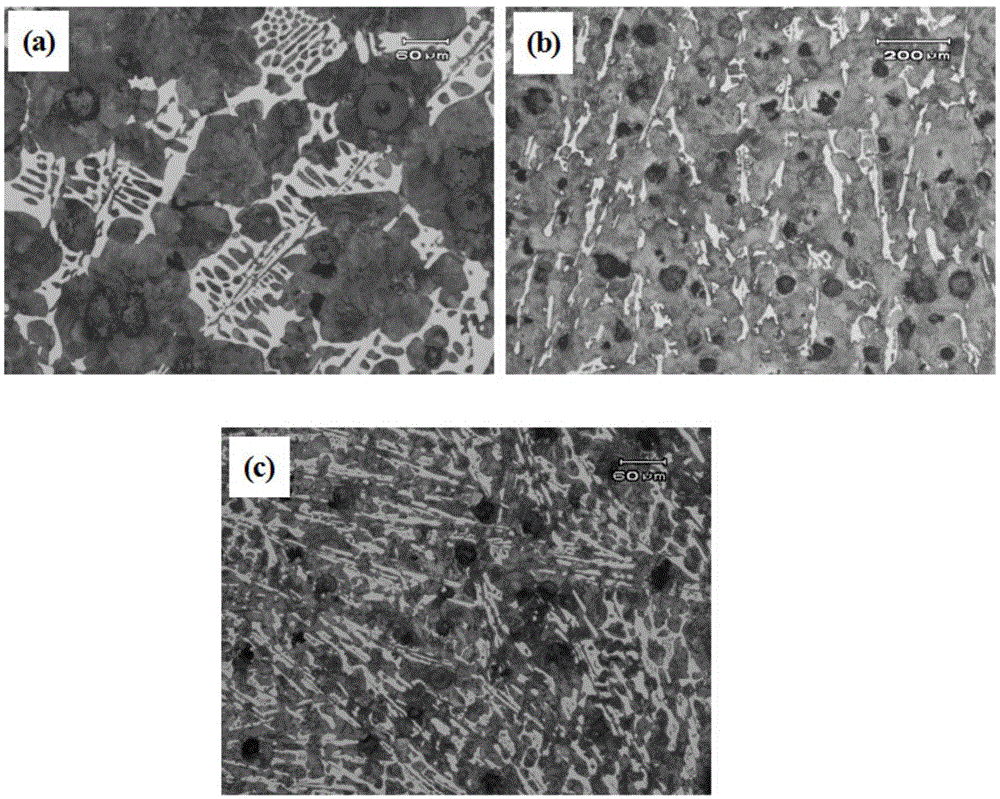

Examples

preparation example Construction

[0028] The present invention also provides a method for preparing the carbide-containing austempering ductile iron, including: ① preparation of raw materials and smelting in an intermediate frequency furnace; ② spheroidizing and inoculation treatment of molten iron; ③ austempering heat treatment. The specific process is as follows:

[0029]The first step of raw material preparation: the raw materials are pig iron, scrap steel, ferromolybdenum, ferromanganese, ferrovanadium, chromium, nickel, copper, silicon, etc., put the prepared raw materials into the intermediate frequency induction furnace, heat up and melt, and then release the balls to obtain the raw material of ductile cast iron. molten iron. The second step of nodularization and inoculation treatment: use FeSiMg8RE5 nodularizer and SiFe75 inoculant, the addition amount is 1.0-1.6% and 0.3-1.0% of the weight of the original molten iron of ductile iron, respectively, and the nodular cast iron after spheroidization and in...

Embodiment 1

[0031] The chemical composition of the austempering ductile iron containing carbides in this example is (wt.%): C3.45%, Si2.45%, Cr0.34%, Mn0.75%, Mo0.34%, V0.032 %, Ni0.25%, Cu0.19%, Mg0.018%, RE0.036%, S0.009%, P0.020%, Fe balance. The heat treatment system adopted by the CADI ductile iron is as follows: the austenitizing temperature is 880°C, the holding time is 1.5h;

Embodiment 2

[0035] The chemical composition of the austempering ductile iron containing carbides in this example is (wt.%): C3.43%, Si2.21%, Cr0.46%, Mn0.49%, Mo0.31%, V0.048 %, Ni0.43%, Cu0.16%, Mg0.019%, RE0.032%, S0.012%, P0.035%, Fe balance. The heat treatment system adopted by the CADI ductile iron is as follows: the austenitizing temperature is 920°C, the holding time is 1.5h;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com