Thickened oil cracking and viscosity-reducing method based on nano-catalysis and microwave heating

A technology of microwave heating and nano-catalysis, which is used in earth-moving drilling, preparation of test samples, and production of fluids, etc., can solve the problems of high cost of oil-soluble viscosity reduction process, rising water content of oil wells, and small application range, and achieve energy utilization. good rate, less oil pollution in the reservoir, and good viscosity reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

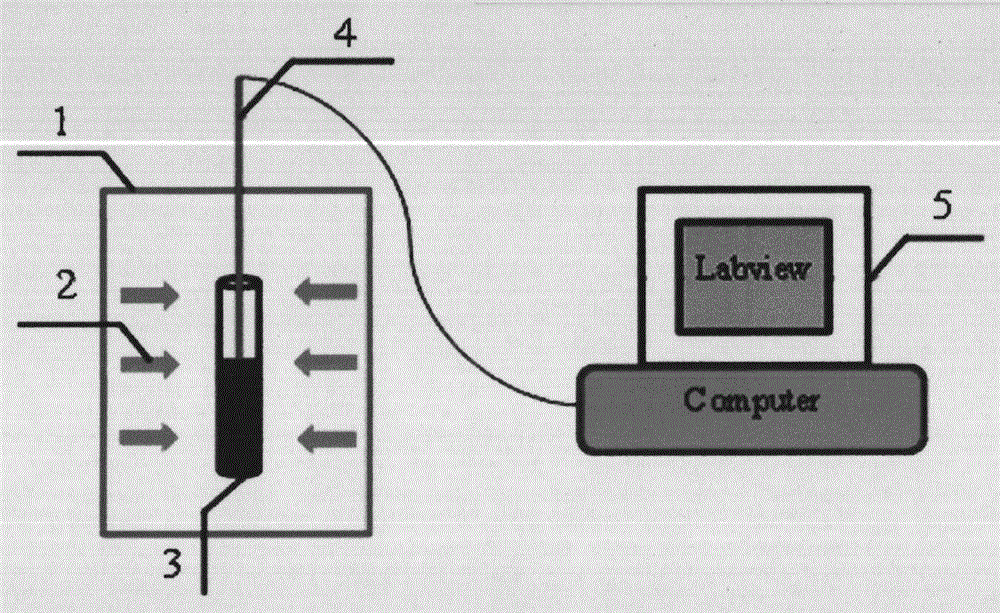

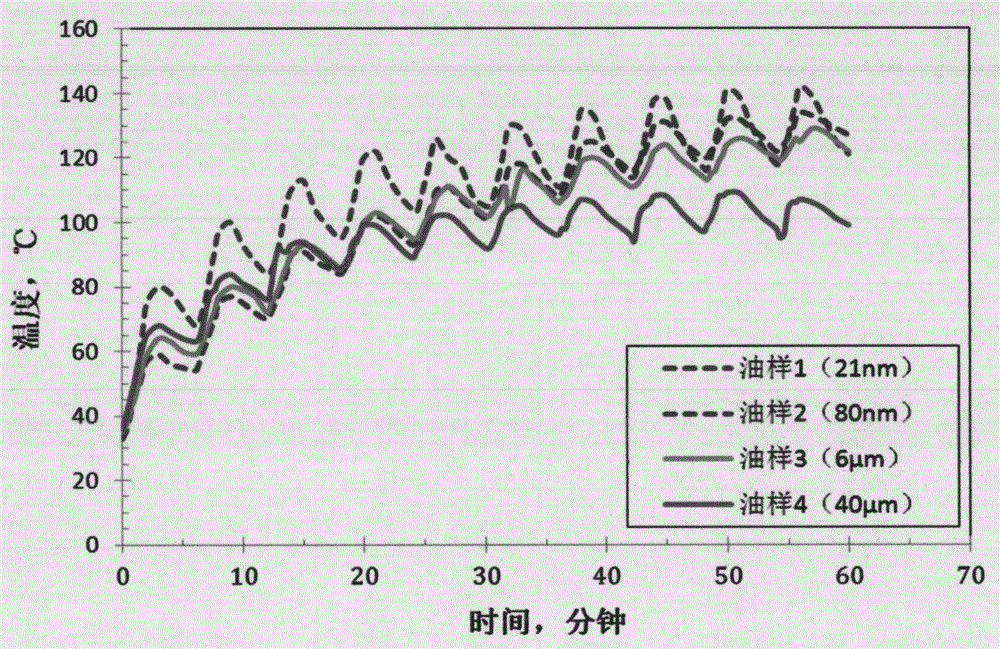

[0026] Embodiment 1 (using the carbon nano-catalyst adopted in the present invention): at first select the ultra-heavy oil of a domestic oil field as the target oil sample, and its original viscosity is 57800mPa s (30 ℃, 10s -1 ); select carbon nanoparticles with a particle size of 21nm as the catalyst; mix the oil sample, nano catalyst and hydrogen donor (tetrahydronaphthalene) according to a certain ratio, wherein the oil sample volume is 20mL, and the catalyst concentration is 0.5wt% , the hydrogen-donating agent concentration is 1wt%; microwave heating is carried out on the prepared oil sample, using the gradient temperature rise method, heating for 2 minutes, pausing for 4 minutes, and repeating this cycle 10 times, accumulatively heating for 20 minutes; as attached figure 1 As shown, during the heating process, the temperature of the oil sample was collected in real time by thermocouple and Libview software; the fluidity, viscosity and family component changes of the oil ...

Embodiment 2

[0027] Example 2 (using a catalyst with a larger particle size for comparison): As described in Example 1, the difference is that the catalyst is replaced by carbon nanoparticles with a particle size of 80 nm.

Embodiment 3

[0028] Example 3 (comparison using a catalyst with a larger particle size): As described in Example 1, the difference is that the catalyst is replaced by carbon nanoparticles with a particle size of 6 μm. ;

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com