Radiator fin for power module and power module made of the same

A technology for power modules and heat sinks, which can be applied to coatings, electrical components, circuits, etc., and can solve problems such as troublesome mounting and processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] The present invention will be described in further detail below in conjunction with specific examples, but the present invention is not limited to the following examples. The implementation conditions adopted in the examples can be further adjusted according to the different requirements of specific use, and the implementation conditions not indicated are the conditions in routine experiments.

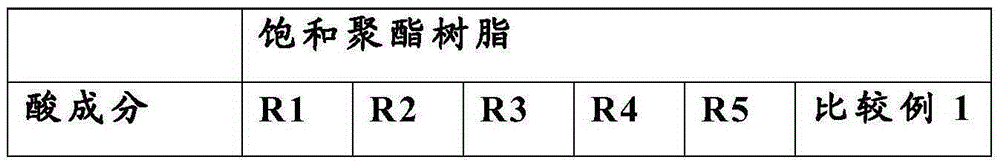

[0060] 1. Synthesis of saturated polyester resin:

[0061] Add each raw material component into the stainless steel reaction kettle with agitator, cooling pipe and thermometer according to the formula amount in Table 1, start stirring, then add the catalyst antimony trioxide relative to the acid component 0.04mol%, and pass nitrogen In the case of , the temperature of the reaction kettle was raised to 160°C to 240°C, and the esterification reaction was carried out for 4 hours. Then release the pressure in the reactor. After 1 hour, the pressure in the reactor drops to 650Pa. Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com