A five-level double-buck grid-connected inverter

A dual step-down, inverter technology, used in electrical components, single-grid parallel feeding arrangements, conversion of AC power input to DC power output, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

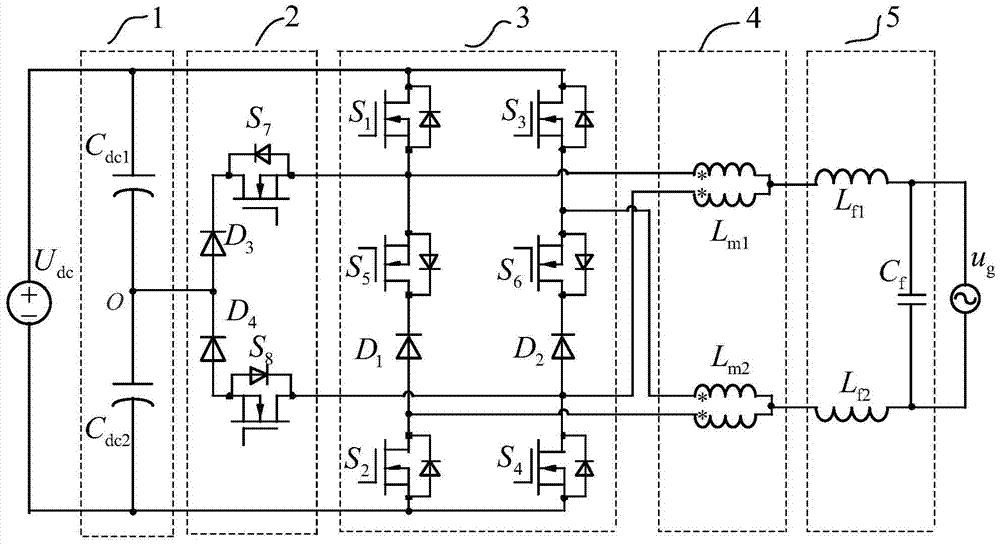

[0075] like figure 2 As shown, the common mode inductor branch 4 includes the first common mode filter inductor L m1 and a second common-mode filter inductor L m2 .

[0076] Input DC source U dc The positive output terminals of the first divider capacitor C dc1 positive pole of the first power switch tube S 1 The drain and the third power switch S 3 The drain connection of the input DC source U dc The negative output terminals are respectively connected to the second voltage dividing capacitor C dc2 The negative pole of the second power switch tube S 2 source of the fourth power switch S 4 The source connection; the first voltage divider capacitor C dc1 The negative pole of the second voltage dividing capacitor C dc2 The anode of the third power diode D 3 The anode of the fourth power diode D 4 The cathode connection; the third power diode D 3 The cathode and the seventh power switch S 7 The drain connection of the seventh power switch tube S 7 The sources of t...

Embodiment 2

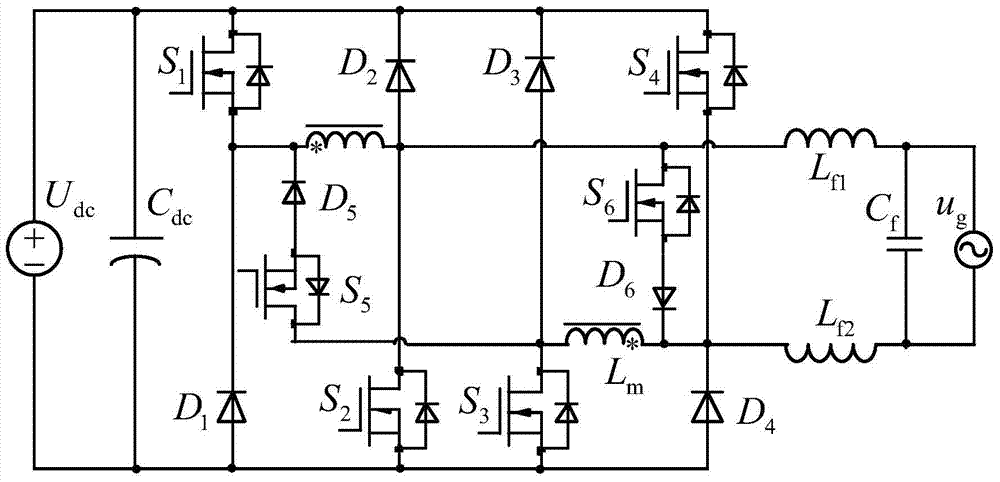

[0090] Such as Figure 5 As shown, the common mode inductance branch 4 includes the common mode filter inductance L m .

[0091] Input DC source U dc The positive output terminals are respectively connected to the first voltage dividing capacitor C dc1 positive pole of the first power switch tube S 1 The drain and the third power switch S 3 The drain connection of the input DC source U dc The negative output terminals are respectively connected to the second voltage dividing capacitor C dc2 The negative pole of the second power switch tube S 2 source of the fourth power switch S 4 The source connection; the first voltage divider capacitor C dc1 The negative pole of the second voltage dividing capacitor C dc2 The anode of the third power diode D 3 The anode of the fourth power diode D 4 The cathode connection; the third power diode D 3 The cathode and the seventh power switch S 7 The drain connection of the seventh power switch tube S 7 The sources of the first po...

Embodiment 3

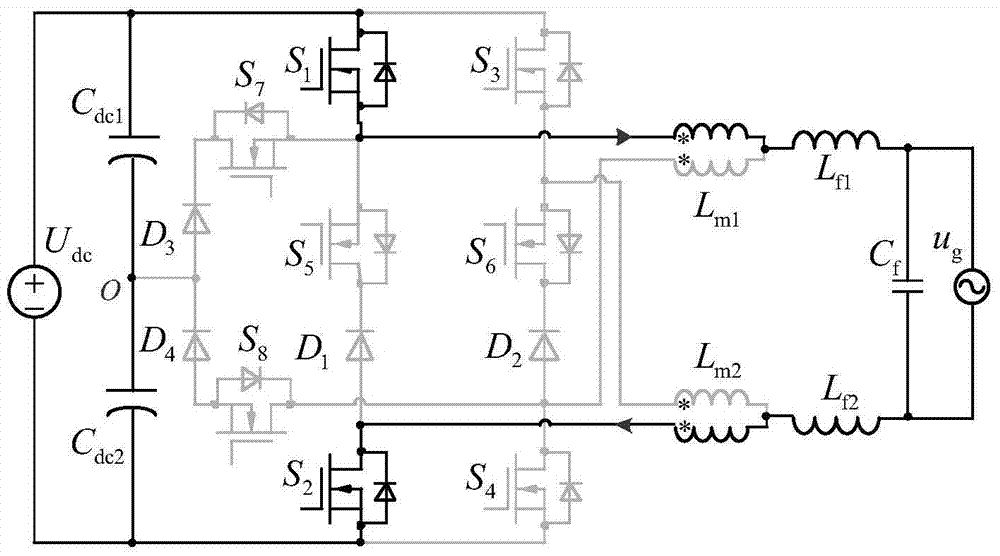

[0094] Such as Image 6 As shown, the common mode inductance branch 4 includes the common mode filter inductance L m .

[0095] Input DC source U dc The positive output terminals are respectively connected to the first voltage dividing capacitor C dc1 positive pole of the first power switch tube S 1 The drain and the third power switch S 3 The drain connection of the input DC source U dc The negative output terminals are respectively connected to the second voltage dividing capacitor C dc2 The negative pole of the second power switch tube S 2 source of the fourth power switch S 4 The source connection; the first voltage divider capacitor C dc1 The negative pole of the second voltage dividing capacitor C dc2 The anode of the third power diode D 3 The anode of the fourth power diode D 4 The cathode connection; the third power diode D 3 The cathode and the seventh power switch S 7 The drain connection of the seventh power switch tube S 7 The sources of the first pow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com