Filtering medium for removing antibiotic-sulfamethoxazole in drinking water, filtering element and preparation method of filtering medium for removing antibiotic-sulfamethoxazole in drinking water

A sulfamethoxazole and filter medium technology, applied in chemical instruments and methods, water pollutants, other chemical processes, etc., can solve the problems of cumbersome operation, secondary pollution, high cost, high removal rate, harm-free, simple method effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

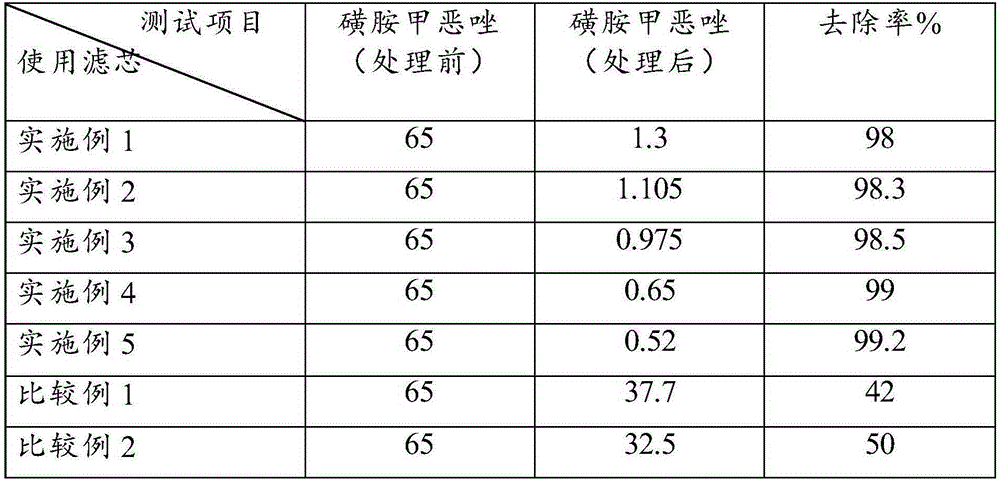

Examples

preparation example Construction

[0021] The invention provides a kind of preparation method of the filter medium that removes sulfamethoxazole in drinking water, it is characterized in that, comprises the following steps:

[0022] a) mixing ultra-high molecular weight polyethylene powder, activated carbon powder, micron molecular sieve powder, nanometer molecular sieve powder and a pore forming agent to obtain a mixture, wherein the ultrahigh molecular weight polyethylene powder, activated carbon powder, micron molecular sieve powder, nanometer molecular sieve powder and foam The weight ratio of the pore agent is 200~300:100~200:50~100:50~100:50~100;

[0023] b) pressing, sintering and cooling the mixture obtained in step a) in a mould;

[0024] The pressing pressure is 0.4MPa-1Mpa; the sintering temperature is 200°C-240°C; the sintering time is 90-150min; the cooling temperature is 40-60°C.

[0025] The present invention first mixes ultra-high molecular weight polyethylene powder, activated carbon powder, m...

Embodiment 1

[0052] (1) Take by weighing particle diameter and be 200g of ultra-high molecular weight polyethylene powder of 80 μm, described ultra-high molecular weight polyethylene is the M-I type product of Beijing Dongfang Petrochemical Co., Ltd. Auxiliary No. 2 Factory, and its molecular weight is 1,500,000;

[0053] (2) Weighing 100g of medical activated carbon powder with a particle diameter of 100 μm, the specific surface area of the medical activated carbon is 800m 2 / g;

[0054] (3) Take by weighing particle diameter and be 50g of micron molecular sieve of 2 μ m;

[0055] (4) taking by weighing particle diameter is 1nm nano molecular sieve 50g;

[0056] (5) Take 50g of pore forming agent;

[0057] (6) Put the above five kinds of powders into a mechanical stirrer and stir for 10 minutes to mix evenly;

[0058] (7) Fill the mixed powder into a tubular mold, press under a hydraulic pressure of 0.7 MPa, and sinter at a temperature of 230° C. for 120 minutes;

[0059] (8) Natura...

Embodiment 2

[0061] (1) Take ultra-high molecular weight polyethylene powder 250g, described ultra-high molecular weight polyethylene is the M-III type product of Beijing Dongfang Petrochemical Co., Ltd. Auxiliary No. 2 Factory, and its molecular weight is 3.5 million;

[0062] (2) Take by weighing medical active carbon powder 150g, the specific surface area of described medical active carbon is 1500m 2 / g;

[0063] (3) Take by weighing particle diameter and be 75g of micron molecular sieve of 3 μ m;

[0064] (4) taking by weighing particle diameter is 2nm nanometer molecular sieve 75g;

[0065] (5) Take 75g of pore forming agent;

[0066] (6) Put the above five kinds of powders into a spiral agitator and stir for 10 minutes to mix evenly;

[0067] (7) Fill the mixed powder into a tubular mold, press under a hydraulic pressure of 0.6MPa, and sinter at a temperature of 230° C. for 100 minutes;

[0068] (8) Naturally cool to 50° C. and then release the mold with a siloxane uranium rele...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com